2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

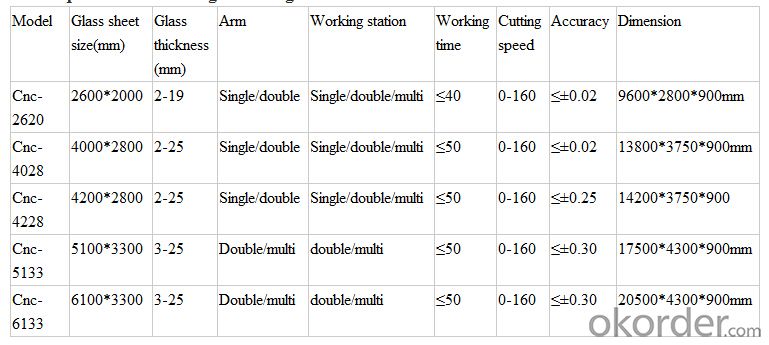

2. Technical parameter:

3. Main components

a, Turning angle: adjustable, from 95 to 98 degree.

b, Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

c, Induction system: two sets of photoelectric sensors to ensure safety operation.

d, Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

e, Suction system: introduced double layer suction, strong absorption.

f, Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

g, Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

h, Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

i, Operation mode: The machine has two kinds controlling mode(automation and manual)

j, Operation screen: Color LCD screen interface

k, Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:What kind of cutting fluid is used in organic glass processing?

- SCC790 glass cutting fluid has excellent biological stability and settlement. SCC790 glass cutting fluid does not contain chlorine, nitrite, phenol and other harmful substances. It belongs to environmental friendly cutting fluid.

- Q:Waste glass processing equipment

- Auxiliary equipment: fuel storage and supply system; fan and air supply system; combustion system

- Q:Glass mechanical grinding, grinding wheel mesh 180, belonging to the grinding edge? What is the appearance quality?

- 180 the glass of the grinding wheel of the target wheel must be opaque and visible. A washing forming section, visible grinding machine, wheel configuration: No. 1, wheel 180*, No. 2, wheel 300*, wheel 3, 400--500, 2 sets of polishing wheels (resin wheel)After tempering glass is generally not recommended for grinding 1. first in the process of grinding wheel 1, adjust properly it will break the glass and the conveyor belt are likely to scrap (we will destroy the 2 synchronous belt 2.) after tempering grinding will damage much toughened glass compressive stress layer after grinding blew the chance increased

- Q:How is glass produced? How much does it cost to open a glass plant and what equipment do we need?

- What kind of glass factory do you prefer? A toughened glass factory, an ordinary glass factory and so on. The investment in the toughened glass factory is much lower than that of the ordinary glass factory

- Q:Is it complicated to produce double glass? We invest about how much money?

- The equipment for making glass is not very complicated, so it can be done with several machines. Cutting tube, sealing, oven, holding furnace. That's all. But now it's harder for sealing workers. A total investment of about one hundred thousand can be done.

- Q:Can organic glass be machined?

- Can be processed, acrylic plate processing with milling machine processing, no problem

- Q:Toughened glass production equipment and price

- 9 grinding head beveling machine more than 80 thousand; 19 thousand basic type profiled machines; drilling machine 18 thousand; washing machine price is unknown, specifications are type 2500, but also several class cleaning; normally want bilateral straight edge grinding machine, the price is unknown, probably need yiershiwan;

- Q:Which equipment should be needed for a glass curtain wall processing plant?

- It depends on how much money you invest, how much equipment you have, and how many products you have, but the more you invest

- Q:What are the equipment for making glass?

- Glass manufacturing process is more and more popular now is pull, float, stamping production of flat glass

- Q:Who knows how the glass is processed into fiberglass? How much is the approximate price of the equipment?

- Its raw materials are mainly waste and broken glass. The process has high energy consumption and poor product quality. It is a process prohibited by the state.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches