YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-4228 full automatic CNC glass cutting machine

Product General Description

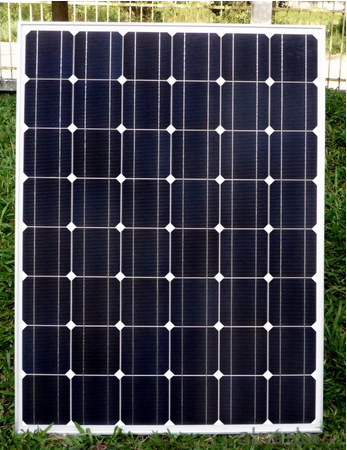

A photovoltaic (in short PV) module is a packaged, connected assembly of typically 6×10 solar cells. Solar Photovoltaic panels constitute the solar array of a photovoltaic system that generates and supplies solar electricityin commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 365 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, a solar inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

Physical characteristic

Equipment frame: guarantee accuracy and keep the shape.

Cutting tool apron: cutting head can rotate 360 degree.

Table top: HDF board

Felt: imported felt, smooth and anti-static

Cutting oil: pneumatic input oil automatically, cutting and oil synchronization

Transfer system: Synchronized belt transfer automatically.

Mechanical parts

Table top: HDF board

Rack: KHK

Transfer belt: Barbieri

Cutting wheel: Germany Bohle

Electrical parts

Microsoft windows interface

Voltage: 380V/50HZ, equipped with transformer.

Motor: Japan YASKAWA sever motor

Approach switch: Switzerland ELCO

Control card: Italy imported TECNOS (match with Italy OPTIMA SOFTWARE)

Main electrical parts: Japan IDEC Relay, Schneider A. C. Contactor

Air proportional valve: Japan SMC

Calculate capacity automatically

- Q:How do we polish the plexiglass after processing?

- Landlord: glass wool top with leather polishing. The specific method is. If the workpiece is bar, workpiece rotation, leather surface with a little powder grinding paste, the amount must be less. If the workpiece is not a bar, with a polishing cloth. To be stained with a little polishing wax.

- Q:How much is the equipment for toughened glass production?

- Type 2436 (2440 * 3660) flat steel furnace is about 900 thousand or so, the prices of different manufacturers are different. Matching pretreatment equipment: 9, grinding machine linear machine about 40 thousand; 9 grinding head beveling machine more than 80 thousand;

- Q:How much does a set of insulating glass aluminum strips require?

- Hollow glass aluminum bars in the past few years, the market is relatively hot, but the equipment requires high accuracy, it is estimated that the price is not cheap.

- Q:How much will it cost to machine ordinary glass into toughened glass? Where can I buy it?

- Different from the raw material, the ordinary glass can be burned by tempering furnace and cooled into toughened glass. Machine made Guangzhou more, of course, more expensive abroad, and good quality. Generally open a steel plant, no 4 million, do not open.

- Q:Is it complicated to produce double glass? We invest about how much money?

- The equipment for making glass is not very complicated, so it can be done with several machines. Cutting tube, sealing, oven, holding furnace. That's all. But now it's harder for sealing workers. A total investment of about one hundred thousand can be done.

- Q:What equipments are used in glass production?

- Grinding angle: special machine, angle grinder.Drilling equipment: bench drill, double sided drilling etc.. Dig holes, cut with water.Silk screen: screen printing platform, screen board, scraper, oven, conditional Optional machine printing equipment.Tempering: flat tempering furnace, bending tempering furnace.Coating: vacuum magnetron sputtering coating machine, divided into hanging furnace, horizontal roller circulation furnace.Packaging cleaning: belt machine, cleaning machine, polishing machine.

- Q:Can organic glass be machined?

- Can be processed, acrylic plate processing with milling machine processing, no problem

- Q:How to polish plexiglass and acrylic machine after machining?

- The flame polishing machine adopts electrochemical technology and uses the special reaction device to extract the oxyhydrogen gas from the water

- Q:Which equipment should be needed for a glass curtain wall processing plant?

- Crane, two-component glue injection machine, double sawing, sawing platform, angle machine, drilling and milling machine, air compressor and fixture fixture.

- Q:What are the main equipments for making insulating glass? How much would a whole set of funds be?

- Aluminum insulated glass equipment also needs a butyl coating machine, two component punch or not, a vertical production line of about 10 million

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches