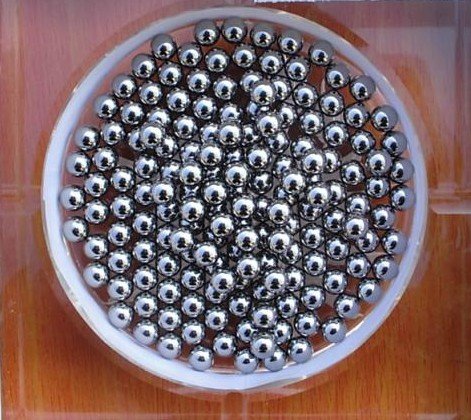

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Ball

MAIN PRODUCTS:

1. Material: AISI304, 316L, 420C, 430, 440C

2. Steel ball, with material AISI 1008-1086.

3. Chrome steel ball,with material: AISI52100

4. Flying saucer steel ball

5. Precision casting, including auto parts, machine parts, hardware handles, etc.

CHARACTER OF PRODUCTS:

1.The Grade of our products is from G10 to G1000

2.The dimension is from 0.5 mm to 25.4 mm.

3.The products from us are widely used in several industries, such as hardware, sliders, ball bearing lead screw, wheels, toys, bicycles, bearings, trust bearings pulleys, chemical industries, etc.

DETAIL SPECIFICATION:

|

Item |

SS304,316L,420C,440C Stainless steel ball |

|

Category |

Stainless Steel Ball |

|

Material |

AISI 420 430 440 SS304 316L |

|

Size |

0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

|

Grade |

G100-G3000 |

|

Hardness ( HRC) |

HRC58-65 |

|

Application |

Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

|

Standard |

GB/T-308-2002, GB/T1148-93 |

|

Matched Standard |

DIN, JIS, ASME |

|

Certification |

ISO |

|

Packing |

Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

|

Place of original |

Shandong province, China |

|

Delivery |

Within 30 days or confirmed while placing order |

- Q:Are stainless steel balls used in any textile dyeing machinery?

- Stainless steel balls find widespread use in textile dyeing machinery, a fact widely acknowledged. Crafted from top-notch stainless steel material, these balls boast exceptional resistance to corrosion, abrasion, and heat. Various components of the dyeing machinery, such as dyeing vessels, drums, and machines, benefit from the utilization of these balls. By agitating the textile materials, stainless steel balls enhance the dyeing process, ensuring superior dye penetration and color fastness. Moreover, their durability and longevity contribute to the overall robustness of the machinery, thanks to their ability to withstand wear and tear. Furthermore, their ease of cleaning and maintenance renders them a go-to choice for textile dyeing machinery.

- Q:Are stainless steel balls used in petrochemical industries?

- Stainless steel balls find widespread application in petrochemical industries. Crafted from top-notch stainless steel alloys, these balls showcase exceptional resistance to corrosion and boast remarkable durability, rendering them ideal for a range of petrochemical uses. Commonly employed in valves, pumps, and other machinery handling corrosive fluids and gases, these industries favor stainless steel balls owing to their ability to endure rigorous operating conditions such as elevated pressures and temperatures. Furthermore, their non-reactive properties guarantee the absence of any contamination in the processed petrochemical products.

- Q:Are stainless steel balls used in fuel cells?

- Fuel cells commonly utilize stainless steel balls. These electrochemical devices transform the chemical energy of a fuel, like hydrogen, into electricity via an oxidation-reduction reaction. In fuel cells, stainless steel balls often serve as a catalyst support material. They possess a large surface area that facilitates the catalytic reactions, enabling the conversion of fuel to electricity. The selection of stainless steel balls stems from their durability, resistance to corrosion, and ability to withstand the challenging conditions within fuel cells. Moreover, their high thermal conductivity aids in dissipating the heat generated during fuel cell operation. All in all, the presence of stainless steel balls significantly contributes to the improved performance and extended lifespan of fuel cells.

- Q:Are stainless steel balls used in any semiconductor manufacturing equipment?

- Yes, stainless steel balls are used in semiconductor manufacturing equipment. Stainless steel balls are commonly used in semiconductor manufacturing equipment, particularly in wafer handling systems and precision machinery. They are often used as bearings or rollers in various stages of the semiconductor manufacturing process, including wafer loading, wafer cleaning, wafer polishing, and wafer inspection. Stainless steel balls are preferred in these applications due to their corrosion resistance, high strength, and precision performance, ensuring smooth and precise movement of the equipment. Additionally, stainless steel balls have low magnetic permeability, making them suitable for use in sensitive semiconductor manufacturing environments.

- Q:What are the different precision grades available for stainless steel balls?

- Stainless steel balls are available in several precision grades, which are determined by their dimensional accuracy and surface quality. The most common precision grades for stainless steel balls are G10, G16, G25, G40, G60, and G100. G10 represents the highest precision grade, indicating a diameter tolerance of ±0.000025 inches and a sphericity tolerance of 0.000012 inches. It also has a surface roughness of approximately 0.00001 inches. The next precision grade is G16, which has a slightly larger diameter tolerance of ±0.000039 inches and a sphericity tolerance of 0.00002 inches. Its surface roughness typically measures around 0.000015 inches. Another commonly used precision grade is G25, with a diameter tolerance of ±0.000049 inches and a sphericity tolerance of 0.000025 inches. The surface roughness for this grade is usually around 0.00002 inches. Moving on to G40, this grade has a larger diameter tolerance of ±0.000078 inches and a sphericity tolerance of 0.000039 inches. The surface roughness is typically around 0.000025 inches. G60, with a diameter tolerance of ±0.000118 inches and a sphericity tolerance of 0.000059 inches, comes next. The surface roughness for this grade is usually around 0.000032 inches. Lastly, G100 represents the lowest precision grade, with a diameter tolerance of ±0.000197 inches and a sphericity tolerance of 0.000099 inches. The surface roughness typically measures around 0.000039 inches. These precision grades offer different levels of dimensional accuracy and surface quality for stainless steel balls, catering to various industrial applications that have specific precision requirements.

- Q:Can stainless steel balls be used in fluid filtration systems?

- Yes, stainless steel balls can be used in fluid filtration systems. Stainless steel balls are known for their corrosion resistance, strength, and durability, making them suitable for a wide range of applications, including fluid filtration. They can be used as part of a filtration system to separate solid particles or impurities from liquids or gases. The smooth surface of stainless steel balls allows for efficient fluid flow, while their chemical resistance ensures they can withstand the harsh conditions often found in filtration systems. Additionally, stainless steel balls can be easily cleaned and sterilized, making them a hygienic choice for fluid filtration applications.

- Q:How are stainless steel balls used in bearings?

- Stainless steel balls are commonly used in bearings due to their corrosion resistance and high durability. They are inserted between the inner and outer races of a bearing to reduce friction and enable smooth rotation. These balls provide support and facilitate the transfer of loads, helping the bearing to operate efficiently and withstand heavy loads and high speeds.

- Q:What are the differences between ordinary stainless steel ball valves and high temperature ball valves?

- The main difference between high temperature ball valve and normal temperature ball valve is different from the manufacturing process,

- Q:Are stainless steel balls resistant to rust?

- Yes, stainless steel balls are resistant to rust. Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium. The presence of chromium forms a thin layer of chromium oxide on the surface of the steel, which acts as a protective barrier against corrosion and rust. This layer is self-repairing, meaning that if it is scratched or damaged, it will quickly reform and continue to provide protection. Therefore, stainless steel balls are highly resistant to rust and can be used in various applications where corrosion resistance is required, such as in bearings, valves, and other precision components.

- Q:Are stainless steel balls used in ammunition?

- Yes, stainless steel balls are commonly used in certain types of ammunition, such as shotgun slugs or air gun pellets. However, they are not as widespread as traditional lead or copper projectiles. Stainless steel balls offer specific advantages, including improved penetration and resistance to corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords