1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

A53(A,B),20#,10#,SS400-SS490,600 Series,400 Series,300 Series,Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series

Certification:

SGS,ISO,RoHS,IBR,BV,UL,BSI,API,CE

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

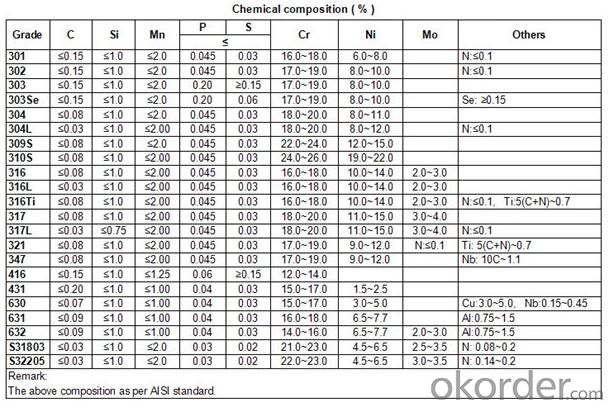

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q:Are stainless steel bars suitable for wastewater treatment facilities?

- Yes, stainless steel bars are highly suitable for wastewater treatment facilities. Stainless steel possesses excellent corrosion resistance properties, making it ideal for environments with high levels of moisture and chemicals, such as those found in wastewater treatment facilities. It can withstand the corrosive effects of various wastewater components, including acids, alkalis, and organic compounds, which can cause significant damage to other materials over time. Additionally, stainless steel bars are durable, hygienic, and easy to clean, ensuring long-lasting performance and maintaining the required sanitary standards in wastewater treatment facilities.

- Q:Can stainless steel bars be used in the mining industry?

- Yes, stainless steel bars can be used in the mining industry. Stainless steel is known for its high strength, durability, and corrosion resistance, making it suitable for various applications in the mining sector. Stainless steel bars can be used in the construction of mining equipment, such as crushers, screens, and conveyors, as well as in the fabrication of structural components for mining infrastructure. Additionally, stainless steel bars can withstand harsh environmental conditions commonly encountered in mining operations, including exposure to moisture, chemicals, and abrasive materials. Overall, the use of stainless steel bars in the mining industry helps ensure the longevity and reliability of mining equipment and structures.

- Q:Can stainless steel bars be used in the power plant manufacturing industry?

- Yes, stainless steel bars can be used in the power plant manufacturing industry. Stainless steel is highly resistant to corrosion, heat, and pressure, making it suitable for various applications in power plants such as turbine blades, valves, and piping systems. Stainless steel's durability and strength make it a reliable choice for withstanding harsh operating conditions and maintaining the efficiency and safety of power generation equipment.

- Q:How do you measure the hardness of a stainless steel bar?

- The hardness of a stainless steel bar can be measured using various methods, but the most common technique is through the use of a hardness testing machine called a Rockwell hardness tester. This device applies a specific amount of force to an indenter, which is then pressed into the surface of the stainless steel bar. The depth of penetration is measured, and this value is used to determine the hardness of the material. To measure the hardness of a stainless steel bar using a Rockwell hardness tester, the following steps are typically followed: 1. Prepare the stainless steel bar by ensuring it is clean and free from any surface contaminants that may affect the test results. 2. Select the appropriate Rockwell hardness scale based on the grade and type of stainless steel being tested. Common scales used for stainless steel include Rockwell C (HRC) and Rockwell B (HRB). 3. Place the stainless steel bar on the anvil of the Rockwell hardness tester, ensuring it is securely positioned. 4. Adjust the machine to the desired test load and indenter type as specified by the hardness scale selected. For example, Rockwell C typically uses a 150 kg test load and a diamond cone-shaped indenter. 5. Activate the machine and allow the indenter to penetrate the surface of the stainless steel bar for a specific duration, usually a few seconds. 6. Once the test is complete, the machine will display the hardness value on its digital or analog readout. This value represents the resistance of the stainless steel bar to indentation and is expressed in a Rockwell hardness number (e.g., HRC 50). It is important to note that the hardness measurement obtained using a Rockwell hardness tester is not the only indicator of a stainless steel bar's properties. Other factors such as tensile strength, corrosion resistance, and metallurgical structure also contribute to its overall performance.

- Q:Are stainless steel bars suitable for the oil and gas industry?

- Yes, stainless steel bars are highly suitable for the oil and gas industry. Stainless steel has excellent corrosion resistance, high temperature strength, and durability, making it ideal for harsh environments and corrosive fluids encountered in oil and gas operations. Additionally, stainless steel bars offer enhanced mechanical properties and can withstand extreme pressure, making them a reliable choice for various applications in the industry.

- Q:Are stainless steel bars suitable for architectural balustrades?

- Indeed, architectural balustrades benefit greatly from the use of stainless steel bars. As a material, stainless steel boasts high durability and resistance to corrosion, rendering it perfect for outdoor installations like balustrades. Moreover, stainless steel demands minimal maintenance, ensuring little effort is needed to keep it in pristine condition over the years. Furthermore, its sleek and contemporary look enhances the overall visual appeal of buildings and structures. Stainless steel bars can be crafted in a multitude of sizes and designs, catering to diverse architectural styles and needs. Ultimately, stainless steel bars offer a robust and reliable solution for architectural balustrades, guaranteeing strength and security.

- Q:Can stainless steel bars be used in automotive exhaust systems?

- Indeed, automotive exhaust systems can make use of stainless steel bars. The extensive utilization of stainless steel in exhaust systems is attributed to its exceptional resistance against corrosion and heat. It possesses the capability to endure the extreme temperatures and adverse conditions to which exhaust systems are typically subjected. By offering durability, longevity, and superior performance, stainless steel bars emerge as a favored option for manufacturers and individuals seeking to enhance their exhaust systems.

- Q:What are the different types of stainless steel bar surface treatments for improved aesthetics?

- There are several different types of stainless steel bar surface treatments that can be used to enhance aesthetics. Some of the common ones include: 1. Mirror Polishing: This treatment involves buffing the surface of the stainless steel bar to achieve a highly reflective, mirror-like finish. It not only improves the appearance but also provides a smooth and easy-to-clean surface. 2. Brushed Finish: This treatment creates a uniform, brushed pattern on the stainless steel surface. It is achieved by brushing the surface with abrasive materials in a consistent direction, resulting in a textured finish that hides scratches and fingerprints. 3. Bead Blasting: In this treatment, tiny glass beads are shot at high pressure onto the stainless steel surface. This creates a matte, non-reflective finish that is smooth to touch. Bead blasting also helps to remove any surface imperfections and gives the bar a uniform appearance. 4. Electropolishing: This is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth, shiny finish. It not only enhances the aesthetics but also improves the corrosion resistance and cleanliness of the bar. 5. PVD Coating: Physical Vapor Deposition (PVD) coating is a method where a thin layer of colored metal or ceramic is deposited onto the stainless steel surface. This creates a durable and decorative finish that can be tailored to various colors and patterns. 6. Powder Coating: In this technique, a dry powder is applied to the stainless steel bar surface and then heated to form a hard, protective coating. Powder coating provides a wide range of color options and can create a smooth or textured finish depending on the desired aesthetic. By selecting the appropriate surface treatment, stainless steel bars can be transformed into visually appealing products that suit various applications and environments.

- Q:Are stainless steel bars resistant to low temperatures?

- Yes, stainless steel bars are generally resistant to low temperatures. Stainless steel has excellent cryogenic properties and remains strong and ductile even at extremely cold temperatures.

- Q:What are the different cutting techniques for stainless steel bars?

- There are several cutting techniques commonly used for stainless steel bars, including abrasive cutting, band saw cutting, plasma cutting, and laser cutting. Each technique offers its own advantages and considerations in terms of precision, speed, cost, and the type of cut required. The choice of cutting technique depends on the specific requirements of the project and the desired outcome.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords