All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

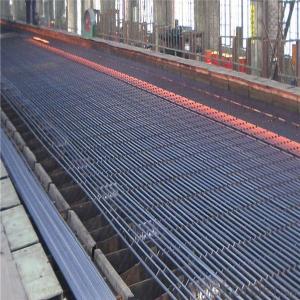

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to ensure proper compaction of concrete around steel rebars in construction?

Proper compaction of concrete around steel rebars in construction is ensured through a combination of techniques and measures. Firstly, the concrete mix is designed with the right proportions of cement, aggregates, water, and admixtures to achieve the desired workability and strength. During placement, skilled workers use vibrating tools, such as poker vibrators or vibrating screeds, to consolidate the concrete and remove any air voids. This ensures that the concrete flows properly around the rebars and fills all the gaps. Additionally, proper formwork design and reinforcement placement allow for easy access to the concrete with vibrators, ensuring uniform compaction throughout the structure. Inspection and testing of the concrete and rebars, such as slump tests and reinforcement checks, are conducted to verify proper compaction and adherence to construction standards. Overall, a combination of well-designed concrete mixes, skilled labor, appropriate tools, and quality control measures are implemented to ensure the proper compaction of concrete around steel rebars in construction.

What is the minimum bend diameter for steel rebars?

The minimum bend diameter for steel rebars is typically determined by the rebar size and grade, but it is generally recommended to be at least four times the diameter of the rebar.

What are the implications of steel rebar theft on the progress and security of construction projects?

Steel rebar theft can have significant implications on the progress and security of construction projects. Firstly, it can lead to delays and disruptions in construction timelines as contractors often need to wait for replacement materials, causing project completion to be delayed. This can result in increased costs and financial losses for all stakeholders involved. Moreover, the theft of steel rebar can compromise the structural integrity of buildings, putting the safety of workers and future occupants at risk. Additionally, the theft of construction materials raises concerns about the security of construction sites, requiring additional security measures and expenses to prevent further thefts. Overall, steel rebar theft negatively impacts both the progress and security of construction projects, necessitating increased vigilance and preventative measures to mitigate these risks.

How are steel rebars transported and stored on a construction site?

Steel rebars are typically transported to a construction site using trucks or trailers and are unloaded using cranes or forklifts. Once on the site, rebars are usually stored in a designated area, often in a horizontal position on racks or stands to prevent them from bending or getting damaged. They may also be bundled together and secured to prevent movement.

Wholesale Steel Rebars from supplier in Turkmenistan

Whether you are involved in construction, infrastructure development, or any other industry that requires Steel Rebars, we have you covered. Our high-quality Steel Rebars are manufactured to international standards, ensuring durability and reliability in every project.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We have a well-established distribution network in Turkmenistan, allowing us to deliver Steel Rebars to your job site efficiently. Our team of experts is always available to provide you with accurate and competitive quotations, tailored to your specific requirements.

Furthermore, we offer comprehensive technical support to assist you throughout the procurement process. Whether you need assistance with product selection, technical specifications, or any other aspect of your project, our knowledgeable staff is here to help. We can provide guidance on the best Steel Rebars for your application and offer recommendations based on our extensive industry experience.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. We believe in providing value-added services that go beyond just supplying Steel Rebars. Our aim is to contribute to the success of your projects by providing reliable products, exceptional service, and valuable insights.

Partner with us for all your Steel Rebars needs in Turkmenistan, and experience a seamless procurement process backed by the expertise of a Fortune Global 500 company. Contact us today to discuss your requirements and benefit from our comprehensive range of products and services.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We have a well-established distribution network in Turkmenistan, allowing us to deliver Steel Rebars to your job site efficiently. Our team of experts is always available to provide you with accurate and competitive quotations, tailored to your specific requirements.

Furthermore, we offer comprehensive technical support to assist you throughout the procurement process. Whether you need assistance with product selection, technical specifications, or any other aspect of your project, our knowledgeable staff is here to help. We can provide guidance on the best Steel Rebars for your application and offer recommendations based on our extensive industry experience.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. We believe in providing value-added services that go beyond just supplying Steel Rebars. Our aim is to contribute to the success of your projects by providing reliable products, exceptional service, and valuable insights.

Partner with us for all your Steel Rebars needs in Turkmenistan, and experience a seamless procurement process backed by the expertise of a Fortune Global 500 company. Contact us today to discuss your requirements and benefit from our comprehensive range of products and services.