All Categories

- - Steel Wire Rod

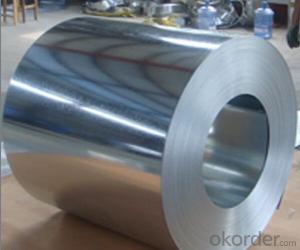

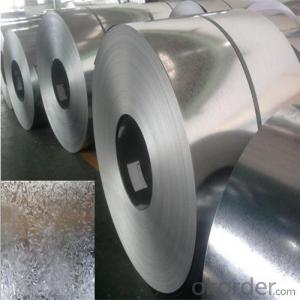

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

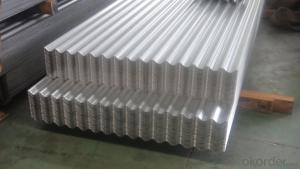

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the advancements in coil slitting technology for precision cutting in the production of metal furniture and fixtures?

Coil slitting technology for precision cutting in the production of metal furniture and fixtures has seen significant advancements in recent years. These advancements primarily revolve around improving the accuracy, speed, and efficiency of the process.

One major advancement is the development of high-tech slitting machines that utilize advanced computer numerical control (CNC) systems. These systems allow for precise control and adjustment of cutting parameters, resulting in higher accuracy and consistency in the slitting process.

Furthermore, the introduction of laser-guided slitting technology has greatly enhanced precision cutting in metal furniture and fixtures production. Laser systems provide real-time feedback and guidance, ensuring the slitting blade follows the desired cutting path with utmost precision, even on complex patterns or irregular shapes.

In addition, improved blade materials and designs have enhanced the durability and longevity of slitting blades, reducing the need for frequent blade replacements and downtime. These advancements have not only improved overall productivity but also reduced costs associated with maintenance and blade replacements.

Moreover, automation and integration with digital systems have streamlined the coil slitting process. Automated material handling systems, along with advanced software and control systems, allow for seamless integration between different stages of production, minimizing human error, and optimizing efficiency.

Overall, these advancements in coil slitting technology have revolutionized the production of metal furniture and fixtures by enabling more precise, efficient, and cost-effective cutting processes.

What are the environmental considerations in the manufacturing of steel coils?

There are several environmental considerations in the manufacturing of steel coils. Firstly, the extraction of iron ore, which is the primary raw material for steel production, can lead to deforestation and habitat destruction. Additionally, the mining process can generate large amounts of waste materials and result in soil and water pollution.

During the actual manufacturing process, the use of high energy-consuming blast furnaces and the combustion of fossil fuels for heat generation contribute to greenhouse gas emissions, including carbon dioxide and methane. These emissions contribute to climate change and air pollution.

Moreover, the steel manufacturing industry is a significant consumer of water, requiring vast amounts for cooling, cleaning, and processing purposes. The extraction and consumption of water can put pressure on local water sources, leading to water scarcity and affecting ecosystems and communities in the vicinity of the steel mills.

Furthermore, the disposal of waste materials such as slag, dust, and sludge generated during steel production requires careful management to prevent contamination of soil and water systems. Proper treatment and disposal methods are necessary to minimize the environmental impact.

Overall, addressing these environmental considerations requires implementing sustainable practices, such as using recycled materials, improving energy efficiency, reducing emissions, conserving water, and adopting responsible waste management strategies in the manufacturing of steel coils.

What is the purpose of a coil's ID and OD?

The purpose of a coil's ID (inner diameter) and OD (outer diameter) is to determine the size and fit of the coil within a specific application. The ID is important for compatibility with the machinery or equipment in which the coil will be installed, ensuring a proper fit and efficient functioning. The OD, on the other hand, is crucial for determining the overall dimensions of the coil, allowing for accurate measurements and calculations during manufacturing and installation.

Wholesale Steel Coils from supplier in Switzerland

Our team is dedicated to providing you with top-quality Steel Coils products and exceptional customer service. We understand the importance of timely and reliable deliveries, and we strive to meet your specific requirements and deadlines. With our extensive network of suppliers and partners, we can source the highest quality Steel Coils products at competitive prices.

In addition to sales and quotations, we also offer technical support to assist you with any questions or concerns you may have regarding Steel Coils. Our team of experts is available to provide guidance and advice on product selection, application, and maintenance. We are committed to ensuring that you have all the information and support you need to make informed decisions for your projects.

Switzerland is a key market for us, and we have a deep understanding of the local business environment. Our years of experience in the Swiss market have allowed us to develop strong relationships with local suppliers and customers, enabling us to provide you with valuable insights and expertise. We are familiar with the specific requirements and regulations of the Swiss market, and we can help you navigate any challenges or obstacles that may arise during the procurement process.

Beyond business opportunities, Switzerland offers a wealth of attractions and activities for both business and leisure travelers. The country's stunning landscapes, including the Swiss Alps and pristine lakes, provide a picturesque backdrop for outdoor activities such as hiking, skiing, and mountain biking. The cities are known for their cleanliness, efficiency, and high quality of life. You can explore the charming old towns, visit world-class museums, and indulge in Swiss cuisine and hospitality. Switzerland is also famous for its luxury watches and delicious chocolate, making it a paradise for shopping enthusiasts and food lovers.

Whether you are a local business in Switzerland or an international company looking to enter the Swiss market, we are here to support your Steel Coils procurement needs. Contact us today to discuss your requirements and let us help you achieve success in Switzerland.

In addition to sales and quotations, we also offer technical support to assist you with any questions or concerns you may have regarding Steel Coils. Our team of experts is available to provide guidance and advice on product selection, application, and maintenance. We are committed to ensuring that you have all the information and support you need to make informed decisions for your projects.

Switzerland is a key market for us, and we have a deep understanding of the local business environment. Our years of experience in the Swiss market have allowed us to develop strong relationships with local suppliers and customers, enabling us to provide you with valuable insights and expertise. We are familiar with the specific requirements and regulations of the Swiss market, and we can help you navigate any challenges or obstacles that may arise during the procurement process.

Beyond business opportunities, Switzerland offers a wealth of attractions and activities for both business and leisure travelers. The country's stunning landscapes, including the Swiss Alps and pristine lakes, provide a picturesque backdrop for outdoor activities such as hiking, skiing, and mountain biking. The cities are known for their cleanliness, efficiency, and high quality of life. You can explore the charming old towns, visit world-class museums, and indulge in Swiss cuisine and hospitality. Switzerland is also famous for its luxury watches and delicious chocolate, making it a paradise for shopping enthusiasts and food lovers.

Whether you are a local business in Switzerland or an international company looking to enter the Swiss market, we are here to support your Steel Coils procurement needs. Contact us today to discuss your requirements and let us help you achieve success in Switzerland.