All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

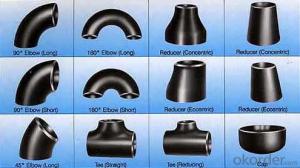

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

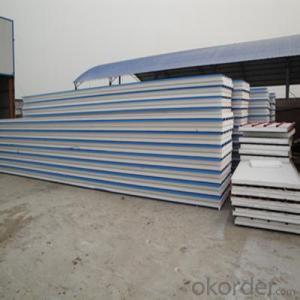

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Steel Wire RodView More

Steel CoilsView More

Steel ProfilesView More

Steel PipesView More

Stainless SteelView More

TinplateView More

Special SteelView More

Steel SheetsView More

Steel RebarsView More

Steel StripsView More

Hot Rolled SteelView More

Cold Rolled SteelView More

Pre-painted SteelView More

Seamless Steel PipeView More

Welded Steel PipeView More

Hollow Steel TubesView More

Galvanized PipeView More

Stainless Steel CoilView More

Stainless Steel SheetView More

Stainless Steel PlateView More

Stainless Steel StripsView More

Electrolytic Tinplate CoilView More

Electrolytic Tinplate SheetView More

Stainless Steel RebarsView More

Q & A

How has the steel manufacturing process evolved over time?

The steel manufacturing process has evolved significantly over time, with advancements in technology and innovation driving major changes. Initially, steel was produced using the Bessemer process in the mid-19th century, which involved blowing air through molten iron to remove impurities. This was later replaced by the basic oxygen process, which improved the quality and efficiency of steel production.

In recent years, the introduction of electric arc furnaces has revolutionized the steel manufacturing process. These furnaces use electricity to melt scrap metal, allowing for more flexibility in the types of materials that can be used. This method also reduces energy consumption and emissions compared to traditional methods.

Moreover, the development of continuous casting has streamlined the production process. Instead of creating individual ingots, continuous casting allows for the direct production of steel billets, slabs, or blooms. This eliminates the need for additional steps and reduces waste.

Additionally, automation and computer control systems have been integrated into steel manufacturing plants, optimizing operations and improving safety. These advancements have led to increased productivity and reduced costs.

Overall, the steel manufacturing process has evolved to become more efficient, environmentally friendly, and technologically advanced, meeting the growing demands of various industries while reducing its impact on the environment.

What role does steel play in the aerospace industry?

Steel plays a crucial role in the aerospace industry as it is commonly used in the construction of aircraft structures, such as wings, fuselages, and landing gear. Its high strength-to-weight ratio makes it ideal for ensuring the structural integrity and safety of aircraft while keeping weight to a minimum. Additionally, steel is also used in engine components and various other parts due to its durability, heat resistance, and ability to withstand extreme conditions.

How is steel produced from iron ore?

Steel is produced from iron ore through a process called ironmaking, where iron ore is smelted in a blast furnace with coke (a carbon-rich fuel) and limestone. The intense heat in the furnace causes the coke to react with oxygen, producing carbon monoxide which reduces the iron ore to molten iron. The limestone acts as a flux, removing impurities and forming slag. The molten iron is then refined and converted into steel through various processes, including oxygen blowing, electric arc furnaces, or basic oxygen furnaces.

Wholesale Steel from supplier in Swaziland

Whether you are looking for structural steel, reinforcement bars, steel pipes, or any other steel product, we have you covered. Our team of experienced professionals is dedicated to delivering high-quality products that meet international standards. We work closely with our customers to understand their specific requirements and provide customized solutions that best suit their needs.

In addition to our sales services, we also offer competitive pricing and efficient delivery options to ensure a smooth procurement process. Our strong network of suppliers and logistics partners enables us to deliver your steel products on time, every time.

Furthermore, we understand the importance of technical support in the steel industry. Our team of experts is always ready to assist you with any technical queries or challenges you may face. From product recommendations to installation guidance, we are committed to providing comprehensive support throughout your project.

As a subsidiary of CNBM, we benefit from the resources, expertise, and global network of this Fortune Global 500 company. This allows us to stay at the forefront of industry trends and technologies, ensuring that we can offer innovative solutions to our customers.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional products and services. Whether you are a small contractor or a large-scale developer, we are here to meet all your steel procurement needs in Swaziland.

Contact us today for a quotation or any inquiries you may have. Let us be your trusted partner in the steel industry.

In addition to our sales services, we also offer competitive pricing and efficient delivery options to ensure a smooth procurement process. Our strong network of suppliers and logistics partners enables us to deliver your steel products on time, every time.

Furthermore, we understand the importance of technical support in the steel industry. Our team of experts is always ready to assist you with any technical queries or challenges you may face. From product recommendations to installation guidance, we are committed to providing comprehensive support throughout your project.

As a subsidiary of CNBM, we benefit from the resources, expertise, and global network of this Fortune Global 500 company. This allows us to stay at the forefront of industry trends and technologies, ensuring that we can offer innovative solutions to our customers.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional products and services. Whether you are a small contractor or a large-scale developer, we are here to meet all your steel procurement needs in Swaziland.

Contact us today for a quotation or any inquiries you may have. Let us be your trusted partner in the steel industry.