All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel coils tested for their impact strength in automotive safety systems?

Steel coils used in automotive safety systems are typically tested for their impact strength through a variety of methods, including but not limited to, drop testing and tensile testing. In drop testing, a steel coil is subjected to controlled impacts from various heights and angles to simulate real-world collision scenarios. Tensile testing involves applying a pulling force to the coil until it reaches its breaking point, allowing engineers to determine its strength and performance under extreme conditions. These tests help ensure that steel coils used in automotive safety systems can withstand the impact forces experienced during accidents, thus enhancing vehicle safety.

What measures are taken to prevent coil edge cracking during the fabrication of metal doors and windows?

There are several measures taken to prevent coil edge cracking during the fabrication of metal doors and windows. First, the coil edges are carefully inspected for any defects or irregularities before they are processed. Proper handling techniques are employed to minimize any potential damage to the coil edges during transportation and storage. Additionally, precise cutting and bending techniques are used during the fabrication process to ensure that the coil edges are not subjected to excessive stress or strain. Finally, the use of suitable lubricants and coatings can help reduce friction and improve the overall integrity of the coil edges, thereby preventing cracking.

How are steel coils prepared for the production of metal railings and fences?

Steel coils are prepared for the production of metal railings and fences by undergoing a series of steps. First, the coils are unwound and straightened to remove any coils or twists. Then, they are cut into appropriate lengths and sent through a cleaning process to remove any rust, dirt, or impurities. After cleaning, the coils are shaped and molded into the desired railing or fence profiles using various techniques such as rolling, bending, or welding. Finally, the finished products are coated with protective finishes or paints to enhance their durability and aesthetic appeal.

What are the common types of steel used in coil production?

The common types of steel used in coil production are hot-rolled, cold-rolled, and galvanized steel.

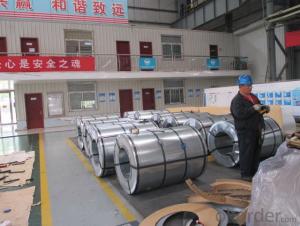

Wholesale Steel Coils from supplier in Poland

We understand the importance of quality and reliability in the steel industry. That is why we work closely with trusted manufacturers to ensure that our Steel Coils meet the highest standards. Our products are thoroughly tested and inspected to ensure their durability and performance.

In addition to supplying Steel Coils, we also offer value-added services such as custom cutting and packaging. Our state-of-the-art facilities and equipment allow us to provide tailored solutions to meet your specific requirements. Whether you need coils in specific dimensions or packaged according to your preferences, we can accommodate your needs.

Furthermore, we understand the importance of timely delivery. With our efficient logistics network, we can ensure that your Steel Coils are delivered to your location in Poland on time. We work closely with reliable shipping partners to guarantee safe and prompt delivery.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional service and support. Our dedicated team of professionals is always available to address any inquiries or concerns you may have. We believe in open communication and transparency throughout the entire process.

In conclusion, as a subsidiary of CNBM, a Fortune Global 500 company, we have the resources, expertise, and dedication to be your trusted supplier of Steel Coils in Poland. Contact us today to discuss your requirements and let us provide you with the best possible solution for your steel coil needs.

In addition to supplying Steel Coils, we also offer value-added services such as custom cutting and packaging. Our state-of-the-art facilities and equipment allow us to provide tailored solutions to meet your specific requirements. Whether you need coils in specific dimensions or packaged according to your preferences, we can accommodate your needs.

Furthermore, we understand the importance of timely delivery. With our efficient logistics network, we can ensure that your Steel Coils are delivered to your location in Poland on time. We work closely with reliable shipping partners to guarantee safe and prompt delivery.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional service and support. Our dedicated team of professionals is always available to address any inquiries or concerns you may have. We believe in open communication and transparency throughout the entire process.

In conclusion, as a subsidiary of CNBM, a Fortune Global 500 company, we have the resources, expertise, and dedication to be your trusted supplier of Steel Coils in Poland. Contact us today to discuss your requirements and let us provide you with the best possible solution for your steel coil needs.