All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the key mechanical properties of aluminum profiles, and how are they tested?

The key mechanical properties of aluminum profiles include strength, ductility, hardness, and toughness. These properties determine the material's ability to withstand external forces and its overall performance in various applications.

To test these properties, several methods are employed. Tensile testing is commonly used to evaluate the strength and ductility of aluminum profiles by subjecting them to a controlled pulling force until they fracture. Hardness testing measures the material's resistance to indentation, providing an indication of its overall strength and wear resistance. Impact testing evaluates the toughness and ability of the aluminum to absorb energy under sudden loading conditions. Additionally, bending tests assess the material's flexibility and deformation behavior. These tests enable manufacturers, engineers, and researchers to ensure that aluminum profiles meet the required mechanical specifications for specific applications.

How do aluminum profiles meet the fire safety standards for different applications?

Aluminum profiles meet fire safety standards for different applications through a combination of their inherent properties and the use of appropriate fire retardant coatings. Aluminum has a high melting point and does not contribute to the spread of fire. Additionally, it forms a protective oxide layer that acts as a barrier against heat and flames. To further enhance fire safety, aluminum profiles can be treated with fire retardant coatings that provide additional insulation and prevent ignition. These coatings are designed to delay the spread of fire and reduce smoke emissions. Overall, aluminum profiles are a safe choice for various applications as they meet the required fire safety standards.

How can you recycle and reuse old aluminum profiles?

There are several ways to recycle and reuse old aluminum profiles. Firstly, they can be taken to a recycling center where they will be melted down and used to create new aluminum products. Alternatively, the profiles can be repurposed for various DIY projects such as crafting decorative items, creating shelving units, or even constructing furniture. By recycling and reusing old aluminum profiles, we can reduce waste and contribute to a more sustainable future.

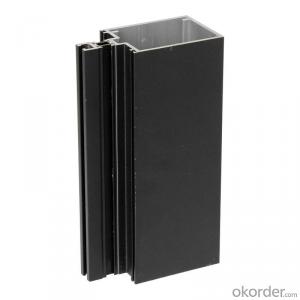

Wholesale Aluminum Profiles from supplier in Palestine

We understand the importance of delivering high-quality products, and our Aluminum Profiles are manufactured using advanced technology and strict quality control measures to ensure durability and reliability. Our team of experienced professionals is dedicated to providing exceptional technical support, assisting you throughout the entire process, from product selection to installation.

We take pride in our comprehensive quotations, which provide you with a detailed breakdown of costs and specifications, allowing you to make informed decisions. Our transparent pricing ensures that you receive fair and competitive rates for our top-quality Aluminum Profiles.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer a seamless procurement experience, ensuring timely delivery and efficient customer service.

Our deep understanding of the Palestine market gives us valuable insights into local regulations and requirements. This knowledge allows us to tailor our products and services to meet your specific needs, ensuring the success of your projects.

When you choose us as your supplier of Aluminum Profiles in Palestine, you can trust that you are partnering with a reputable and reliable company. We are committed to exceeding your expectations and providing you with the highest level of customer satisfaction. Contact us today to discuss your Aluminum Profiles requirements, and let us help you achieve your project goals.

We take pride in our comprehensive quotations, which provide you with a detailed breakdown of costs and specifications, allowing you to make informed decisions. Our transparent pricing ensures that you receive fair and competitive rates for our top-quality Aluminum Profiles.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer a seamless procurement experience, ensuring timely delivery and efficient customer service.

Our deep understanding of the Palestine market gives us valuable insights into local regulations and requirements. This knowledge allows us to tailor our products and services to meet your specific needs, ensuring the success of your projects.

When you choose us as your supplier of Aluminum Profiles in Palestine, you can trust that you are partnering with a reputable and reliable company. We are committed to exceeding your expectations and providing you with the highest level of customer satisfaction. Contact us today to discuss your Aluminum Profiles requirements, and let us help you achieve your project goals.