All Categories

- - Steel Wire Rod

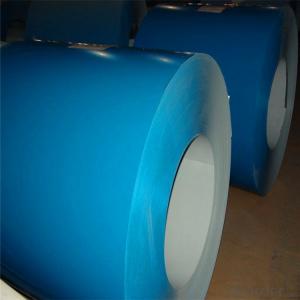

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does special steel enhance the structural integrity of modern skyscrapers and bridges?

Special steel enhances the structural integrity of modern skyscrapers and bridges by providing superior strength, durability, and resistance to various forces such as wind, earthquakes, and heavy loads. Its unique properties, such as high tensile strength and low weight, allow for the construction of taller and more lightweight structures. Additionally, special steel's corrosion resistance helps protect against environmental factors, ensuring the longevity and safety of these architectural marvels.

How does steel alloy selection impact its performance in challenging environmental conditions?

Steel alloy selection has a significant impact on the performance of steel in challenging environmental conditions. Different alloys have varying levels of corrosion resistance, strength, and ductility, which directly affect how well the steel can withstand exposure to extreme temperatures, humidity, chemicals, or abrasive elements. The proper selection of steel alloy can ensure enhanced durability, extended lifespan, and optimal performance in harsh environments.

Explain the impact of sulfur and phosphorus on the machinability of steel.

Sulfur and phosphorus have a significant impact on the machinability of steel. These elements are considered impurities in steel and have adverse effects on the material's cutting and machining properties. Sulfur, in particular, tends to form brittle compounds with iron, resulting in poor machinability. It increases tool wear, reduces cutting tool life, and promotes the formation of built-up edge (BUE) on the cutting tool, leading to poor surface finish and dimensional accuracy. Phosphorus, on the other hand, increases the strength and hardness of steel, making it more difficult to machine. It also has a detrimental effect on the toughness and ductility of steel, further complicating the machining process. In summary, both sulfur and phosphorus negatively affect the machinability of steel, resulting in reduced productivity, increased costs, and compromised quality of machined components.

What is the role of magnetic testing in steel quality control?

Magnetic testing plays a crucial role in steel quality control by detecting any defects or impurities that may be present in the steel. It is used to assess the magnetic properties of the steel, such as its permeability, coercivity, and magnetic saturation, which can indicate the presence of cracks, inclusions, or other flaws. This non-destructive testing method helps ensure that the steel meets the required quality standards and is suitable for its intended applications.

Wholesale Special Steel from supplier in Pakistan

Our team of experts is dedicated to providing excellent customer service and ensuring that your specific requirements are met. We understand the unique needs of the Pakistan market and can offer customized solutions to meet your project needs.

Whether you are in the construction, automotive, or manufacturing industry, we have the Special Steel products to suit your needs. Our product portfolio includes a wide range of high-quality steel products, such as alloy steel, stainless steel, tool steel, and more.

In addition to our sales services, we also provide quotations to help you determine the cost of your project. Our team will work closely with you to understand your requirements and provide accurate and competitive pricing.

Furthermore, we offer technical support to ensure that you have the right steel products for your project. Our technical experts can provide guidance on material selection, application, and performance, allowing you to make informed decisions.

As a subsidiary of CNBM, we have access to a vast global network of suppliers, ensuring that we can source the highest quality Special Steel products at competitive prices. We are committed to delivering on-time and providing exceptional value to our customers.

Contact us today to learn more about our specialized Special Steel products and how we can support your projects in Pakistan.

Whether you are in the construction, automotive, or manufacturing industry, we have the Special Steel products to suit your needs. Our product portfolio includes a wide range of high-quality steel products, such as alloy steel, stainless steel, tool steel, and more.

In addition to our sales services, we also provide quotations to help you determine the cost of your project. Our team will work closely with you to understand your requirements and provide accurate and competitive pricing.

Furthermore, we offer technical support to ensure that you have the right steel products for your project. Our technical experts can provide guidance on material selection, application, and performance, allowing you to make informed decisions.

As a subsidiary of CNBM, we have access to a vast global network of suppliers, ensuring that we can source the highest quality Special Steel products at competitive prices. We are committed to delivering on-time and providing exceptional value to our customers.

Contact us today to learn more about our specialized Special Steel products and how we can support your projects in Pakistan.