All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

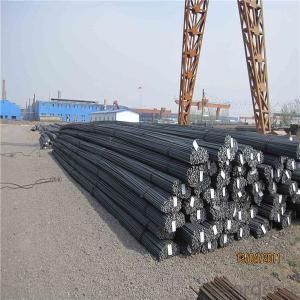

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the choice of rebar material impact the sustainability and environmental footprint of a construction project?

The choice of rebar material can significantly impact the sustainability and environmental footprint of a construction project. Traditional steel rebar production requires a substantial amount of energy and emits significant carbon dioxide (CO2) emissions during the manufacturing process. However, using alternative materials such as fiberglass or recycled steel rebar can reduce the environmental impact. Fiberglass rebar, for example, is lightweight, corrosion-resistant, and does not release harmful chemicals or greenhouse gases during production. On the other hand, utilizing recycled steel rebar reduces the need for mining and extraction of raw materials, conserves energy, and reduces CO2 emissions. Therefore, selecting environmentally-friendly rebar materials can contribute to a more sustainable construction project by minimizing resource depletion, reducing carbon emissions, and promoting circular economy practices.

How do steel rebars affect the overall stability of a building?

Steel rebars greatly enhance the overall stability of a building. They reinforce concrete structures by providing tensile strength, preventing cracks and improving load-bearing capacity. The rebars distribute the stress and load across the building, making it more resistant to bending, shearing, and structural failure. Ultimately, the inclusion of steel rebars significantly increases the durability, safety, and longevity of the building.

How are steel rebars used in the reinforcement of wind turbines and renewable energy infrastructure?

Steel rebars are used in the reinforcement of wind turbines and renewable energy infrastructure to enhance their structural integrity and durability. These rebars are embedded within the concrete foundations and structures of wind turbines, solar panel installations, and other renewable energy infrastructure projects. By providing additional strength and resistance to forces such as wind loads and vibrations, steel rebars ensure the stability and long-term performance of these structures, enabling them to withstand harsh weather conditions and operate efficiently for years to come.

What is the lifespan of steel rebars in a concrete structure?

The lifespan of steel rebars in a concrete structure can vary depending on several factors such as the quality of the rebar, the conditions it is exposed to (such as humidity, temperature, and chemical exposure), and the maintenance and protection measures taken. Generally, steel rebars in a well-designed and properly maintained concrete structure can last for several decades or even longer. However, factors like corrosion and structural loads should be considered, and regular inspections and maintenance are crucial to ensure their longevity.

Wholesale Steel Rebars from supplier in Nicaragua

We are a Steel Rebars supplier serving the Nicaragua, mainly engaged in the sale, quotation, and technical support services of various Steel Rebars products in the Nicaragua region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Rebars procurement services in the Nicaragua. Not only do we have a wide range of Steel Rebars products, but after years of market development in the Nicaragua, we can also provide valuable experience for your projects.