All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

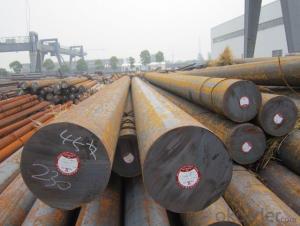

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the challenges in machining special steel components?

There are several challenges in machining special steel components. One of the main challenges is the high hardness and strength of special steel, which makes it difficult to cut and shape. Special steel also has a tendency to work harden, which means it becomes even harder as it is machined, making it more challenging to achieve precise dimensions. Additionally, special steels often have low thermal conductivity, which can result in heat buildup during machining, leading to tool wear and decreased efficiency. Finally, special steel components may have complex geometries or intricate designs, requiring advanced machining techniques and specialized tools. Overall, machining special steel components demands expertise, precision, and careful consideration of the material properties to overcome these challenges effectively.

What is the role of aluminum in steel alloying and what properties does it impart?

Aluminum plays a crucial role in steel alloying as it acts as a deoxidizer and grain refiner. When added in small amounts (typically around 0.01-0.1%), aluminum removes oxygen from the steel, preventing the formation of oxides and improving its overall cleanliness. Additionally, aluminum helps in the formation of fine and uniform grains, leading to improved mechanical properties such as increased strength, toughness, and corrosion resistance.

What are the critical factors that determine the suitability of a steel alloy for a specific application?

The critical factors that determine the suitability of a steel alloy for a specific application include its mechanical properties, such as strength, hardness, and toughness, as well as its corrosion resistance, heat resistance, and weldability. Other factors to consider are the desired weight, cost, and availability of the alloy, as well as any specific requirements for the application, such as electrical conductivity or magnetic properties. Ultimately, the suitability of a steel alloy depends on how well it meets the specific performance, environmental, and cost requirements of the intended application.

Wholesale Special Steel from supplier in Madagascar

Our team of experts is committed to understanding your specific requirements and delivering the highest quality Special Steel products to meet your needs. Whether you are in the automotive, construction, or manufacturing industry, we have the right solutions for your projects.

We offer a wide range of Special Steel products, including alloy steel, tool steel, stainless steel, and carbon steel. These materials are carefully sourced from reputable manufacturers to ensure optimal performance and durability. Our products are available in various forms, such as bars, sheets, plates, and pipes, to provide you with flexibility in your applications.

In addition to our comprehensive product range, we provide exceptional sales, quotation, and technical support services. Our dedicated sales team is always available to assist you in selecting the right Special Steel products for your projects. We offer competitive pricing and flexible payment terms to ensure your procurement process is hassle-free.

Our technical support team consists of experienced engineers who can provide you with valuable insights and recommendations on material selection, design optimization, and product application. We understand the unique challenges of working in Madagascar and can offer tailored solutions to meet your specific requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver a seamless Special Steel procurement experience. We have an extensive network of suppliers and logistics partners, enabling us to provide efficient delivery to any location in Madagascar.

At our core, we believe in building long-term partnerships with our clients. We strive to exceed your expectations by delivering exceptional products and services. Let us be your trusted partner in Special Steel solutions in Madagascar. Contact us today to discuss your project requirements and experience the difference of working with a dedicated Special Steel supplier.

We offer a wide range of Special Steel products, including alloy steel, tool steel, stainless steel, and carbon steel. These materials are carefully sourced from reputable manufacturers to ensure optimal performance and durability. Our products are available in various forms, such as bars, sheets, plates, and pipes, to provide you with flexibility in your applications.

In addition to our comprehensive product range, we provide exceptional sales, quotation, and technical support services. Our dedicated sales team is always available to assist you in selecting the right Special Steel products for your projects. We offer competitive pricing and flexible payment terms to ensure your procurement process is hassle-free.

Our technical support team consists of experienced engineers who can provide you with valuable insights and recommendations on material selection, design optimization, and product application. We understand the unique challenges of working in Madagascar and can offer tailored solutions to meet your specific requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver a seamless Special Steel procurement experience. We have an extensive network of suppliers and logistics partners, enabling us to provide efficient delivery to any location in Madagascar.

At our core, we believe in building long-term partnerships with our clients. We strive to exceed your expectations by delivering exceptional products and services. Let us be your trusted partner in Special Steel solutions in Madagascar. Contact us today to discuss your project requirements and experience the difference of working with a dedicated Special Steel supplier.