All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

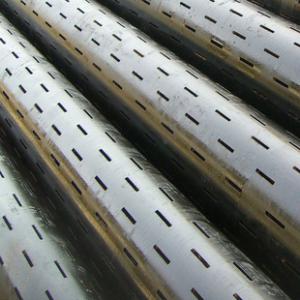

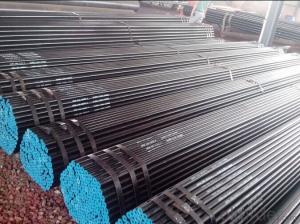

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for pressure testing facilities?

Yes, welded steel pipes can be used for pressure testing facilities. Welded steel pipes are commonly used in various industries for their strength and durability. They have the ability to withstand high pressure and are suitable for conducting pressure tests in facilities where it is necessary to evaluate the integrity and performance of components under different pressure conditions.

How is welded steel pipe protected against external damage?

Welded steel pipes are typically protected against external damage through various methods such as applying coatings, using corrosion inhibitors, and installing protective sleeves or wraps. These protective measures help prevent corrosion, abrasion, and impact damage to ensure the longevity and integrity of the pipe.

What are the common quality defects found in welded steel pipes?

Some common quality defects found in welded steel pipes include lack of fusion, porosity, undercutting, and cracks.

How does the welding process affect the mechanical properties of welded steel pipes?

The welding process can significantly affect the mechanical properties of welded steel pipes. During welding, the heat-affected zone (HAZ) experiences rapid heating and cooling, which can result in changes to the microstructure and mechanical properties of the material. The material in the HAZ may become harder, more brittle, or less ductile, depending on the welding parameters and the steel grade. Additionally, the weld metal itself may have different mechanical properties compared to the base metal. The choice of welding technique, filler material, and post-weld heat treatment can help mitigate these effects and ensure the desired mechanical properties are achieved in the welded steel pipes.

What is the impact of surface defects on the integrity of welded steel pipe?

Surface defects on welded steel pipe can have a significant impact on its integrity. These defects, such as cracks, pits, or porosity, can act as stress concentration points, making the pipe more susceptible to failure under applied loads. They can also provide initiation sites for corrosion, leading to accelerated deterioration of the pipe over time. It is crucial to identify and address surface defects during the welding process to ensure the long-term structural integrity and reliability of the steel pipe.

Wholesale Welded Steel Pipe from supplier in Liechtenstein

Our Welded Steel Pipe products are manufactured using high-quality materials and advanced technology, ensuring durability and excellent performance. We can supply pipes in various sizes, specifications, and grades to meet the specific requirements of your projects in Liechtenstein. Whether you need pipes for construction, infrastructure, or industrial applications, we can provide the right solutions.

In addition to supplying Welded Steel Pipe products, we also offer value-added services such as cutting, threading, and coating to further meet your project needs. Our team of technical experts is available to provide guidance and support, ensuring that you receive the most suitable products and solutions for your applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers and resources, enabling us to offer competitive prices and efficient procurement services. We strive to deliver our products on time and within budget, ensuring customer satisfaction and project success.

We understand the unique requirements and challenges of the Liechtenstein market, and our experience in serving clients in this region allows us to provide tailored services and solutions. Whether you are a contractor, engineer, or project manager, we are committed to working closely with you to ensure that your projects are completed successfully.

Contact us today to discuss your Welded Steel Pipe requirements in Liechtenstein. Our dedicated team is ready to assist you and provide the best solutions for your projects.

In addition to supplying Welded Steel Pipe products, we also offer value-added services such as cutting, threading, and coating to further meet your project needs. Our team of technical experts is available to provide guidance and support, ensuring that you receive the most suitable products and solutions for your applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers and resources, enabling us to offer competitive prices and efficient procurement services. We strive to deliver our products on time and within budget, ensuring customer satisfaction and project success.

We understand the unique requirements and challenges of the Liechtenstein market, and our experience in serving clients in this region allows us to provide tailored services and solutions. Whether you are a contractor, engineer, or project manager, we are committed to working closely with you to ensure that your projects are completed successfully.

Contact us today to discuss your Welded Steel Pipe requirements in Liechtenstein. Our dedicated team is ready to assist you and provide the best solutions for your projects.