All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

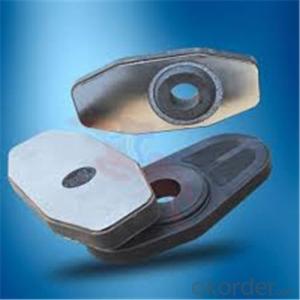

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used in contact with corrosive liquids?

No, monolithic refractories are generally not suitable for use in contact with corrosive liquids as they are prone to chemical attack and degradation.

Can monolithic refractories be used for lining blast furnaces?

Yes, monolithic refractories can be used for lining blast furnaces. Monolithic refractories are composed of a single, homogeneous material and offer excellent thermal shock resistance and high-temperature performance, making them suitable for lining blast furnaces. They can withstand the extreme temperatures and harsh conditions inside the furnace, providing durability and optimal performance.

How do monolithic refractories handle thermal insulation?

Monolithic refractories handle thermal insulation by providing a dense and continuous structure that minimizes heat transfer through conduction. They have low thermal conductivity and high heat capacity, allowing them to withstand high temperatures and provide effective insulation in various industrial applications.

How do monolithic refractories perform in terms of thermal expansion?

Monolithic refractories generally exhibit low thermal expansion, which means they have the ability to withstand high temperatures without significant dimensional changes.

Wholesale Monolithic Refractories from supplier in Libya

We are a Monolithic Refractories supplier serving the Libya, mainly engaged in the sale, quotation, and technical support services of various Monolithic Refractories products in the Libya region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Monolithic Refractories procurement services in the Libya. Not only do we have a wide range of Monolithic Refractories products, but after years of market development in the Libya, we can also provide valuable experience for your projects.

Hot Search

- Monolithic Refractories in South Korea

- Ceramic Fiber Products in Pakistan

- Refractory Bricks in Mongolia

- Raw Materials For Refractory in Slovakia

- Ceramic Fiber Products in Uganda

- Raw Materials For Refractory in Palau

- Refractory Bricks in Dominica

- Refractory Bricks in Australia

- Raw Materials For Refractory in United Arab Emirates

- Ceramic Fiber Products in Moldova