All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

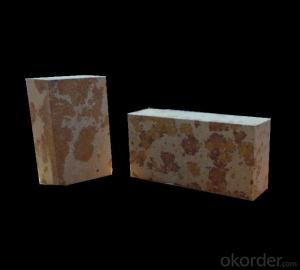

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Discuss the characteristics of low cement castables and their advantages in refractory applications.

Low cement castables are a type of refractory material that contains a relatively low amount of cement compared to traditional castables. This means that the cement content is typically less than 10% by weight.

One of the key characteristics of low cement castables is their high strength and excellent abrasion resistance. This is due to the reduced amount of cement, which allows for a higher proportion of refractory aggregates and additives. As a result, low cement castables have superior mechanical properties, making them suitable for applications that require high strength and resistance to wear and tear.

Another advantage of low cement castables is their improved thermal shock resistance. The reduced cement content allows for a more uniform distribution of refractory aggregates, which helps to minimize thermal stress during rapid heating and cooling cycles. This makes low cement castables ideal for applications that involve frequent temperature changes or thermal cycling.

Furthermore, low cement castables exhibit excellent corrosion resistance, making them suitable for use in aggressive environments where chemical attack is a concern. They also have a lower porosity compared to traditional castables, which improves their resistance to penetration by molten metals or slag.

Overall, the characteristics of low cement castables, including high strength, excellent abrasion resistance, improved thermal shock resistance, and superior corrosion resistance, make them highly desirable for various refractory applications, such as in furnaces, kilns, and other high-temperature industrial processes.

How does chromite contribute to refractory properties?

Chromite contributes to refractory properties by providing high thermal stability and resistance to corrosion. Its high melting point, low thermal expansion coefficient, and excellent thermal conductivity make it an ideal material for refractory applications. Additionally, chromite's chemical stability and resistance to chemical attack from molten metals and slags further enhance its refractory properties.

What are the sources of high-quality graphite for refractory production?

The primary sources of high-quality graphite for refractory production are natural graphite deposits and synthetic graphite production methods. Natural graphite is typically mined from underground or open-pit mines and can be further processed to enhance its purity and properties. Synthetic graphite, on the other hand, is produced through the carbonization of carbon-rich materials, such as petroleum coke or coal tar pitch, under high temperatures. Both natural and synthetic graphite can be used as excellent sources of high-quality graphite for refractory production, depending on the specific requirements of the application.

What are the mechanical properties of refractory raw materials?

The mechanical properties of refractory raw materials refer to their ability to withstand high temperatures, pressure, and mechanical stress without deformation or failure. These properties include high melting points, low thermal conductivity, high compressive strength, and resistance to thermal shock and chemical corrosion.

Wholesale Raw Materials For Refractory from supplier in Germany

Our team of experts understands the unique requirements and demands of the refractory industry in Germany. We work closely with our customers to identify the most suitable raw materials for their specific applications. Our product range includes high-quality alumina, magnesia, chromite, and other refractory materials, sourced from trusted suppliers around the world.

In addition to supplying raw materials, we also provide value-added services such as technical consultation, custom blending, and logistics support. Our dedicated team is always available to assist you with any queries or concerns you may have.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This enables us to stay at the forefront of industry trends and developments, ensuring that we can offer the latest and most innovative solutions to our customers in Germany.

We are committed to building long-term relationships with our customers, based on trust, reliability, and exceptional service. Whether you are involved in steel production, cement manufacturing, or any other refractory-related industry, we have the knowledge and expertise to meet your specific needs.

Contact us today to learn more about our comprehensive range of raw materials for refractory and how we can support your projects in Germany. We look forward to partnering with you and contributing to your success.

In addition to supplying raw materials, we also provide value-added services such as technical consultation, custom blending, and logistics support. Our dedicated team is always available to assist you with any queries or concerns you may have.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This enables us to stay at the forefront of industry trends and developments, ensuring that we can offer the latest and most innovative solutions to our customers in Germany.

We are committed to building long-term relationships with our customers, based on trust, reliability, and exceptional service. Whether you are involved in steel production, cement manufacturing, or any other refractory-related industry, we have the knowledge and expertise to meet your specific needs.

Contact us today to learn more about our comprehensive range of raw materials for refractory and how we can support your projects in Germany. We look forward to partnering with you and contributing to your success.

Hot Search

- Monolithic Refractories in Lesotho

- Ceramic Fiber Products in Mongolia

- Refractory Bricks in Palau

- Raw Materials For Refractory in Germany

- Refractory Bricks in Algeria

- Raw Materials For Refractory in Kazakhstan

- Raw Materials For Refractory in Thailand

- Raw Materials For Refractory in Cyprus

- Refractory Bricks in Serbia

- Refractory Bricks in Tonga