All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

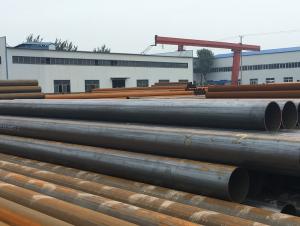

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the cost of welded steel pipe compare to other types of pipes?

The cost of welded steel pipe is generally higher compared to other types of pipes such as PVC or HDPE. This is due to the higher cost of raw materials, the complex manufacturing process involved in welding steel pipes, and the durability and strength that steel pipes offer. However, the long-term benefits of using welded steel pipes, such as their resistance to corrosion and ability to withstand high pressure and temperature, often justify the higher initial cost.

Can welded steel pipe be used for chemical processing plants?

Yes, welded steel pipe can be used for chemical processing plants. Welded steel pipes are commonly used in industrial applications, including chemical processing plants, due to their durability, strength, and ability to withstand high pressures and temperatures. Additionally, welded steel pipes can be constructed to meet specific chemical requirements, such as corrosion resistance, by using appropriate coatings or linings.

How are welded steel pipes protected against mechanical damage?

Welded steel pipes are protected against mechanical damage through various measures such as applying protective coatings, using corrosion-resistant materials, implementing proper handling and transportation practices, and installing additional protective devices like pipe supports and guards.

How do welded steel pipes handle changes in soil conditions?

Welded steel pipes are designed to handle changes in soil conditions due to their inherent strength and flexibility. The welded joints provide additional strength and stability, allowing the pipes to withstand external pressures and movements caused by soil settlement or shifts. The durable nature of steel also ensures that the pipes can resist corrosion and other environmental factors, further enhancing their ability to handle changes in soil conditions over time.

What are the different factors that can affect the tensile strength of welded steel pipe?

There are several factors that can affect the tensile strength of welded steel pipe. These include the type and quality of the steel used, the welding process and technique employed, the heat treatment applied, the presence of any impurities or defects in the weld, and the overall design and dimensions of the pipe. Additionally, factors such as temperature, strain rate, and environmental conditions can also impact the tensile strength of the welded steel pipe.

Wholesale Welded Steel Pipe from supplier in Ecuador

Whether you are in need of standard or customized Welded Steel Pipe products, our team of experts will work closely with you to understand your specific requirements and provide tailored solutions. We have established strong relationships with reputable manufacturers in the industry, ensuring that we can offer high-quality products at competitive prices.

In addition to our sales and procurement services, we also offer technical support to assist you throughout the entire project cycle. Our knowledgeable team can provide guidance on product selection, installation, and maintenance, helping you achieve optimal results.

As a subsidiary of CNBM, we benefit from their extensive resources and global network. This allows us to efficiently manage the procurement process, ensuring timely delivery and cost-effective solutions.

We take pride in our commitment to customer satisfaction and strive to exceed your expectations. Whether you are working on a small-scale project or a large industrial undertaking, we are dedicated to providing reliable products and exceptional service.

Contact us today to discuss your Welded Steel Pipe needs in Ecuador and discover how we can support your projects.

In addition to our sales and procurement services, we also offer technical support to assist you throughout the entire project cycle. Our knowledgeable team can provide guidance on product selection, installation, and maintenance, helping you achieve optimal results.

As a subsidiary of CNBM, we benefit from their extensive resources and global network. This allows us to efficiently manage the procurement process, ensuring timely delivery and cost-effective solutions.

We take pride in our commitment to customer satisfaction and strive to exceed your expectations. Whether you are working on a small-scale project or a large industrial undertaking, we are dedicated to providing reliable products and exceptional service.

Contact us today to discuss your Welded Steel Pipe needs in Ecuador and discover how we can support your projects.