All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

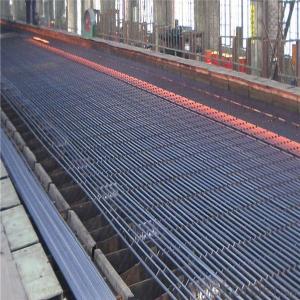

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the choice of steel rebar material and design affect the acoustic properties of a building?

The choice of steel rebar material and design can have a significant impact on the acoustic properties of a building. Steel rebar is commonly used in concrete structures to reinforce them and improve their strength. However, the type of steel material and the design of the rebar can influence how sound is transmitted through the building.

The density and stiffness of the steel material can affect the transmission of sound waves. High-density steel rebar can help block or absorb sound, reducing the amount of noise that enters or exits the building. On the other hand, using low-density steel rebar or improper design can allow sound waves to easily pass through, resulting in poor acoustic insulation.

The design of the rebar, such as its spacing, size, and configuration, can also impact sound transmission. A well-designed rebar structure can help minimize sound transmission by creating barriers and absorbing vibrations. Additionally, the placement of rebar in different areas of the building, such as walls, floors, or ceilings, can help control sound propagation and prevent unwanted noise transfer.

In summary, the choice of steel rebar material and design plays a crucial role in determining the acoustic properties of a building. By selecting appropriate materials and implementing effective designs, it is possible to enhance the building's acoustic insulation, ensuring a more comfortable and peaceful environment.

How do you prevent theft of steel rebars from construction sites?

There are several measures that can be taken to prevent theft of steel rebars from construction sites. Firstly, implementing proper security measures such as installing surveillance cameras, perimeter fencing, and well-lit areas can act as deterrents to potential thieves. Secondly, assigning on-site security personnel who can monitor the site and control access can help prevent unauthorized entry and theft. Additionally, keeping an inventory of all steel rebars and conducting regular checks can help identify any missing items quickly. Finally, collaborating with local law enforcement agencies and sharing information about theft incidents can aid in apprehending culprits and discouraging future thefts.

What are the environmental considerations when sourcing and using steel rebars in construction?

When sourcing and using steel rebars in construction, there are several environmental considerations to take into account. Firstly, the extraction and production of steel can have a significant impact on the environment, as it requires energy-intensive processes and can contribute to greenhouse gas emissions. It is important to source steel rebars from manufacturers that prioritize sustainable practices such as using recycled materials and minimizing waste and emissions.

Additionally, the transportation of steel rebars can contribute to carbon emissions, so it is advisable to source materials locally whenever possible to reduce the environmental footprint.

During the construction phase, it is crucial to handle and store steel rebars properly to prevent damage and corrosion, as this can lead to unnecessary waste and replacement. Proper waste management practices should also be implemented, ensuring that any leftover or scrap steel is recycled rather than ending up in landfills.

Considering the longevity and durability of steel rebars, they can be a sustainable choice in construction. Their strength and ability to withstand harsh conditions can contribute to the longevity of structures, reducing the need for frequent repairs or replacements.

Overall, by sourcing steel rebars responsibly, minimizing transportation emissions, and employing proper handling and waste management practices, the environmental impact of using steel rebars in construction can be significantly reduced.

What measures can be taken to extend the lifespan of steel rebars in corrosive environments?

There are several measures that can be taken to extend the lifespan of steel rebars in corrosive environments. One effective method is to apply a protective coating or paint to the rebars, which acts as a barrier between the steel and the corrosive elements. Additionally, using corrosion-resistant alloys or stainless steel rebars can significantly increase their durability. Regular maintenance and inspections to identify any signs of corrosion early on are also crucial. Moreover, implementing cathodic protection systems or using corrosion inhibitors in concrete can help reduce the corrosive effects on steel rebars. Lastly, proper design and construction practices, including adequate concrete cover and drainage systems, can prevent the accumulation of moisture and corrosive agents.

Wholesale Steel Rebars from supplier in Denmark

We understand the importance of delivering high-quality products and services to meet the specific needs of our customers. Our team of experienced professionals is committed to delivering exceptional customer service and ensuring the smooth execution of every project.

Our Steel Rebars products are manufactured using state-of-the-art technology and adhere to strict quality standards. We offer a wide range of sizes and grades to suit various construction requirements. Our Steel Rebars are known for their durability, strength, and corrosion resistance, making them suitable for a wide range of applications.

In addition to our product offering, we provide comprehensive technical support to assist our customers in selecting the right Steel Rebars for their projects. Our team of experts is available to provide guidance on product specifications, installation techniques, and any other technical queries.

We also understand the importance of competitive pricing and timely delivery. With our strong supply chain capabilities and strategic partnerships, we ensure that our customers receive their orders on time and at competitive prices.

At our company, we strive to build long-term relationships with our customers based on trust, reliability, and exceptional service. We are confident that our comprehensive range of Steel Rebars products, technical expertise, and commitment to customer satisfaction make us the ideal partner for all your Steel Rebars needs in Denmark.

Contact us today to learn more about our products and services and how we can support your construction projects.

Our Steel Rebars products are manufactured using state-of-the-art technology and adhere to strict quality standards. We offer a wide range of sizes and grades to suit various construction requirements. Our Steel Rebars are known for their durability, strength, and corrosion resistance, making them suitable for a wide range of applications.

In addition to our product offering, we provide comprehensive technical support to assist our customers in selecting the right Steel Rebars for their projects. Our team of experts is available to provide guidance on product specifications, installation techniques, and any other technical queries.

We also understand the importance of competitive pricing and timely delivery. With our strong supply chain capabilities and strategic partnerships, we ensure that our customers receive their orders on time and at competitive prices.

At our company, we strive to build long-term relationships with our customers based on trust, reliability, and exceptional service. We are confident that our comprehensive range of Steel Rebars products, technical expertise, and commitment to customer satisfaction make us the ideal partner for all your Steel Rebars needs in Denmark.

Contact us today to learn more about our products and services and how we can support your construction projects.