All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

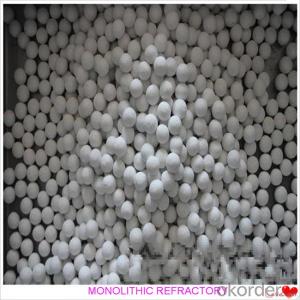

- - Monolithic Refractories

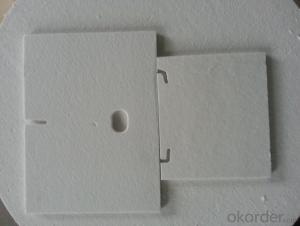

- - Ceramic Fiber Products

- - Refractory Bricks

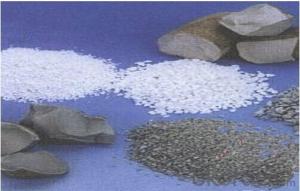

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common methods of refractory installation?

The common methods of refractory installation include gunning, casting, ramming, and bricklaying. Gunning involves spraying refractory material onto a surface using a high-pressure gun. Casting involves pouring a refractory mixture into a mold and allowing it to solidify. Ramming involves compacting refractory material into a desired shape using a pneumatic rammer. Bricklaying involves arranging refractory bricks in a specific pattern using mortar or refractory cement.

What are the refractory materials used in boilers?

Refractory materials commonly used in boilers include fire clay, high alumina, silica, and insulating materials such as ceramic fiber and vermiculite. These materials are chosen for their high temperature resistance and ability to withstand the harsh conditions inside a boiler, such as extreme heat and rapid temperature changes.

What are the main constituents of refractory materials?

The main constituents of refractory materials are oxides of metals such as alumina (Al2O3), silica (SiO2), magnesia (MgO), and zirconia (ZrO2). These materials have high melting points and excellent resistance to heat, making them suitable for applications in high-temperature environments.

Wholesale Refractory Materials from supplier in Comoros

With our wide range of Refractory Materials, we can cater to the needs of industries such as steel, cement, glass, petrochemical, and more in the Comoros. Our products include high-quality refractory bricks, castables, mortars, ceramic fiber products, and insulation materials.

We understand the importance of competitive pricing in the market, and our strong global network allows us to source materials at the best prices. This enables us to offer cost-effective solutions without compromising on quality.

In addition to supplying Refractory Materials, we also provide technical assistance to ensure that you make the right choice for your specific project requirements. Our team of experts can guide you in selecting the most suitable materials, optimizing their application, and providing recommendations for maintenance and repairs.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to ensure a seamless procurement process, from initial inquiry to delivery, ensuring timely and reliable supply of Refractory Materials.

Our years of market presence in the Comoros have provided us with valuable insights and understanding of the local industry. This knowledge allows us to tailor our solutions according to the specific needs and challenges faced in the region. We are committed to providing exceptional customer service and building long-term partnerships based on trust and reliability.

Whether you require Refractory Materials for new construction projects or maintenance and repairs, we have the expertise, product range, and competitive pricing to meet your needs in the Comoros. Contact us today to discuss your requirements and benefit from our comprehensive solutions.

We understand the importance of competitive pricing in the market, and our strong global network allows us to source materials at the best prices. This enables us to offer cost-effective solutions without compromising on quality.

In addition to supplying Refractory Materials, we also provide technical assistance to ensure that you make the right choice for your specific project requirements. Our team of experts can guide you in selecting the most suitable materials, optimizing their application, and providing recommendations for maintenance and repairs.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to ensure a seamless procurement process, from initial inquiry to delivery, ensuring timely and reliable supply of Refractory Materials.

Our years of market presence in the Comoros have provided us with valuable insights and understanding of the local industry. This knowledge allows us to tailor our solutions according to the specific needs and challenges faced in the region. We are committed to providing exceptional customer service and building long-term partnerships based on trust and reliability.

Whether you require Refractory Materials for new construction projects or maintenance and repairs, we have the expertise, product range, and competitive pricing to meet your needs in the Comoros. Contact us today to discuss your requirements and benefit from our comprehensive solutions.

Hot Search

- Monolithic Refractories in Portugal

- Ceramic Fiber Products in Malawi

- Refractory Bricks in Dominica

- Raw Materials For Refractory in Italy

- Ceramic Fiber Products in Azerbaijan

- Monolithic Refractories in Venezuela

- Raw Materials For Refractory in Zambia

- Raw Materials For Refractory in Monaco

- Raw Materials For Refractory in Yemen

- Raw Materials For Refractory in Jamaica