All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

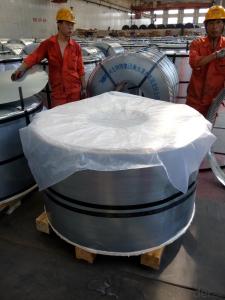

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main factors that affect the surface roughness of electrolytic tinplate coil?

The main factors that affect the surface roughness of electrolytic tinplate coil are the quality of the substrate material, the cleanliness of the surface, the uniformity of the tin coating, the control of the electrolytic process parameters, and the post-processing treatments such as flattening and annealing.

What are the potential applications of electrolytic tinplate coil in the canning industry?

Electrolytic tinplate coil has various potential applications in the canning industry. It is primarily used as a protective coating for metal cans, providing corrosion resistance to ensure the integrity and longevity of canned products. Additionally, its smooth and shiny surface enhances the visual appeal of cans, making them more marketable. The versatility of electrolytic tinplate coil also allows for easy shaping and forming of cans in different sizes and shapes, meeting the diverse packaging needs of the canning industry.

What are the advantages of using electrolytic tinplate coil for packaging?

Electrolytic tinplate coil offers several advantages for packaging. Firstly, it provides excellent protection against corrosion and oxidation, ensuring the preservation and quality of the packaged products. Secondly, it has superior strength and durability, making it suitable for handling and transportation without compromising the integrity of the packaging. Additionally, electrolytic tinplate coil has high heat resistance, allowing it to withstand various temperature conditions, including sterilization processes. Lastly, it offers excellent printability and aesthetic appeal, enabling effective branding and product promotion.

What are the common tin coatings used on electrolytic tinplate coil?

The common tin coatings used on electrolytic tinplate coil are pure tin and tin alloys, such as tin-lead and tin-zinc.

How does the coil handle bending and forming?

The coil is designed to handle bending and forming with ease. Its flexible and malleable nature allows it to be shaped and molded into various forms without breaking or losing its structural integrity. This makes it highly versatile and suitable for a wide range of applications where bending and forming are required.

Wholesale Electrolytic Tinplate Coil from supplier in Brazil

Whether you are in the food packaging, automotive, or other industries that require high-quality tinplate coil products, we have you covered. Our Electrolytic Tinplate Coils are manufactured using advanced technology and meet international quality standards.

When it comes to sales, our dedicated team will assist you in finding the right products to meet your specific requirements. We understand that each project is unique, and we strive to provide personalized solutions to our clients. Our sales representatives are knowledgeable about our products and can provide detailed information and recommendations to help you make informed decisions.

Quotations are an essential part of the procurement process, and we ensure that our quotations are accurate, transparent, and competitive. We take into account factors such as quantity, specifications, and delivery requirements to provide you with the most cost-effective solution. Our goal is to offer competitive pricing without compromising on quality.

Technical support is another service we offer to our clients. Our team of experts is available to provide assistance and guidance throughout your project. Whether you need help with product specifications, application recommendations, or troubleshooting, we are here to ensure your success.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and a global network. This allows us to stay up-to-date with the latest industry trends and technologies. It also enables us to leverage our purchasing power to offer competitive prices to our clients.

We understand the specific challenges and requirements of the Brazilian market. Our years of experience in serving clients in Brazil have given us valuable insights and expertise. We can provide guidance on local regulations, market trends, and best practices to help you navigate the Brazilian market more effectively.

In summary, we are your reliable partner for Electrolytic Tinplate Coil procurement in Brazil. With our extensive product range, sales expertise, competitive pricing, and technical support, we are well-equipped to meet all your needs. Contact us today to discuss your requirements and let us help you achieve your project goals.

When it comes to sales, our dedicated team will assist you in finding the right products to meet your specific requirements. We understand that each project is unique, and we strive to provide personalized solutions to our clients. Our sales representatives are knowledgeable about our products and can provide detailed information and recommendations to help you make informed decisions.

Quotations are an essential part of the procurement process, and we ensure that our quotations are accurate, transparent, and competitive. We take into account factors such as quantity, specifications, and delivery requirements to provide you with the most cost-effective solution. Our goal is to offer competitive pricing without compromising on quality.

Technical support is another service we offer to our clients. Our team of experts is available to provide assistance and guidance throughout your project. Whether you need help with product specifications, application recommendations, or troubleshooting, we are here to ensure your success.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and a global network. This allows us to stay up-to-date with the latest industry trends and technologies. It also enables us to leverage our purchasing power to offer competitive prices to our clients.

We understand the specific challenges and requirements of the Brazilian market. Our years of experience in serving clients in Brazil have given us valuable insights and expertise. We can provide guidance on local regulations, market trends, and best practices to help you navigate the Brazilian market more effectively.

In summary, we are your reliable partner for Electrolytic Tinplate Coil procurement in Brazil. With our extensive product range, sales expertise, competitive pricing, and technical support, we are well-equipped to meet all your needs. Contact us today to discuss your requirements and let us help you achieve your project goals.