All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

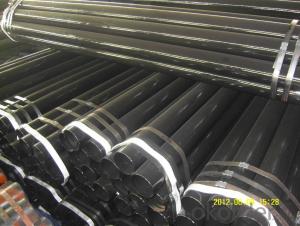

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for food processing plants?

Yes, a welded steel pipe can be used for food processing plants. However, certain considerations need to be taken into account such as the type of steel used, surface finish, and the welding process to ensure compliance with food safety regulations and prevent any contamination risks.

Can welded steel pipe be used for water supply systems?

Yes, welded steel pipe can be used for water supply systems. Welded steel pipes are commonly used in various industries, including water supply systems, due to their durability, strength, and resistance to corrosion. They can handle high-pressure applications and are capable of carrying large volumes of water efficiently. Additionally, welded steel pipes are available in various sizes, making them suitable for different water supply system requirements.

How is a welded steel pipe manufactured?

A welded steel pipe is manufactured through a process called electric resistance welding (ERW). In this process, a flat steel strip is first formed into a cylindrical shape and then passed through a series of rollers to create a longitudinal seam. The edges of the strip are then heated and fused together using an electric current, resulting in a continuous welded joint. After welding, the pipe is further processed to remove any excess material and achieve the desired size and shape. Finally, the pipe undergoes various tests and inspections to ensure its quality and durability before it is ready for use.

Can welded steel pipes be used for conveying liquid petroleum products?

Yes, welded steel pipes can be used for conveying liquid petroleum products. Welded steel pipes are commonly used in the oil and gas industry due to their high strength and durability. Additionally, they provide a secure and reliable means of transporting petroleum products, ensuring minimal leakage or contamination.

What is the impact of formability on the ease of shaping and bending of welded steel pipe?

The formability of welded steel pipe directly affects the ease of shaping and bending. Higher formability allows the pipe to be manipulated into various shapes and angles with less effort. On the other hand, low formability makes the pipe more resistant to shaping and bending, requiring more force and potentially leading to material deformation or failure. Therefore, formability plays a crucial role in determining the flexibility and maneuverability of welded steel pipe during fabrication and installation processes.

Wholesale Welded Steel Pipe from supplier in Benin

We are a Welded Steel Pipe supplier serving the Benin, mainly engaged in the sale, quotation, and technical support services of various Welded Steel Pipe products in the Benin region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Welded Steel Pipe procurement services in the Benin. Not only do we have a wide range of Welded Steel Pipe products, but after years of market development in the Benin, we can also provide valuable experience for your projects.