All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

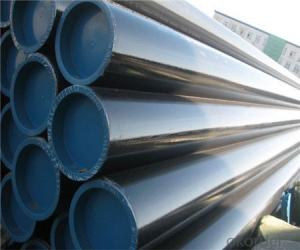

Can hollow steel tubes be used for manufacturing street lamp posts?

Yes, hollow steel tubes can be used for manufacturing street lamp posts. Hollow steel tubes are strong, durable, and can withstand outdoor conditions, making them suitable for supporting street lamps. Additionally, their hollow design allows for easy installation of electrical wiring and reduces the weight of the lamp post while maintaining structural integrity.

How do hollow steel tubes perform in extreme temperature environments?

Hollow steel tubes have excellent performance in extreme temperature environments. Steel is known for its high heat resistance and ability to withstand both extremely low and high temperatures without significant structural changes. This makes hollow steel tubes suitable for a range of applications, from oil and gas pipelines in arctic regions to high-temperature industrial processes. Additionally, steel's thermal conductivity allows it to distribute heat evenly, minimizing the risk of localized overheating or thermal stress. Overall, hollow steel tubes are reliable and durable materials in extreme temperature conditions.

Are hollow steel tubes more cost-effective than solid steel rods?

Yes, hollow steel tubes are generally more cost-effective than solid steel rods. Hollow tubes require less material to manufacture compared to solid rods, reducing production costs. Additionally, hollow tubes offer weight savings, making them easier and cheaper to transport.

What are the considerations for corrosion protection in hollow steel tubes?

There are several considerations for corrosion protection in hollow steel tubes. Firstly, the type of environment the tubes will be exposed to is important. If the tubes will be in a highly corrosive environment, such as near the coast or in an industrial area, a more robust corrosion protection system may be necessary.

Additionally, the coating or treatment applied to the tubes is crucial. Common options include galvanization, where a layer of zinc is applied to the surface, or epoxy coatings. The choice of coating will depend on factors such as cost, desired lifespan, and specific environmental conditions.

Proper maintenance and inspection of the tubes is also essential for corrosion protection. Regularly checking for any signs of corrosion, such as rust or pitting, and promptly addressing them can help prevent further damage.

Lastly, design considerations should be taken into account. Ensuring adequate drainage and ventilation within the hollow tubes can help prevent the accumulation of moisture, which can accelerate corrosion. Additionally, using materials that are compatible with the steel tubes can help prevent galvanic corrosion.

Overall, considering the environmental conditions, choosing the right coating or treatment, regular maintenance, and proper design can all contribute to effective corrosion protection in hollow steel tubes.

Wholesale Hollow Steel Tubes from supplier in Argentina

With our dedication to supplying Hollow Steel Tubes in Argentina, we have become a leading supplier in the industry. Our comprehensive range of products and professional services, including sales, quotations, and technical support, make us the preferred choice for customers.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to abundant resources and capabilities. This enables us to provide a seamless procurement experience for Hollow Steel Tubes in Argentina, ensuring that your needs are met efficiently.

Over the years, we have gained valuable market experience in Argentina. This gives us a deep understanding of the local industry and allows us to provide valuable insights and support for your projects. Whether you require Hollow Steel Tubes for construction, manufacturing, or any other application, we have the expertise to meet your specific requirements.

By choosing us as your trusted Hollow Steel Tubes supplier in Argentina, you can expect reliable products, competitive prices, and exceptional customer service. We are committed to ensuring your satisfaction and success in your projects.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to abundant resources and capabilities. This enables us to provide a seamless procurement experience for Hollow Steel Tubes in Argentina, ensuring that your needs are met efficiently.

Over the years, we have gained valuable market experience in Argentina. This gives us a deep understanding of the local industry and allows us to provide valuable insights and support for your projects. Whether you require Hollow Steel Tubes for construction, manufacturing, or any other application, we have the expertise to meet your specific requirements.

By choosing us as your trusted Hollow Steel Tubes supplier in Argentina, you can expect reliable products, competitive prices, and exceptional customer service. We are committed to ensuring your satisfaction and success in your projects.