All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

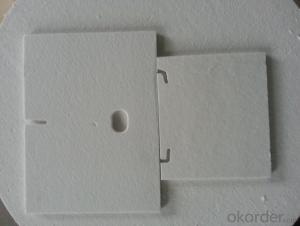

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials perform in kilns for ceramic firing?

Refractory materials in kilns for ceramic firing perform exceptionally well due to their ability to withstand high temperatures without deforming or breaking down. They provide insulation, prevent heat loss, and maintain a consistent temperature within the kiln, resulting in efficient and successful ceramic firing processes.

How do refractory materials contribute to the control of combustion processes in furnaces?

Refractory materials contribute to the control of combustion processes in furnaces by providing a heat-resistant lining that can withstand high temperatures. This lining prevents the heat generated during combustion from escaping, thus ensuring efficient heating and reducing energy waste. Additionally, refractory materials help to protect the structural integrity of the furnace by acting as a barrier against corrosive byproducts of combustion, such as acids and molten metals. Overall, refractory materials play a crucial role in maintaining the stability and efficiency of combustion processes in furnaces.

How are refractory plastics used in construction?

Refractory plastics are used in construction for various applications where high heat resistance is required. They are commonly used as insulation materials in furnaces, kilns, and other high-temperature equipment. Additionally, refractory plastics can be used for lining chimneys, fireplaces, and industrial boilers to prevent heat loss and protect surrounding structures.

Wholesale Refractory Materials from supplier in Angola

Whether you are in need of fire bricks, castables, insulation materials, or any other refractory products, our team is dedicated to providing you with the highest quality materials at competitive prices. We work closely with our customers to understand their specific requirements and offer tailored solutions to meet their needs.

In addition to our sales services, we also provide comprehensive quotations to help you plan and budget for your projects. Our experienced team is well-versed in the local market and can offer valuable insights and guidance to ensure that you make informed decisions.

Furthermore, our technical support team is always ready to assist you with any technical queries or challenges you may face. From installation guidance to troubleshooting, we are committed to ensuring that your projects run smoothly and successfully.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to source and supply a wide range of refractory materials, including those that may be hard to find in the local market. We strive to be your reliable partner for all your refractory materials procurement needs.

Whether you are involved in the steel, cement, glass, or any other industry, we have the knowledge and experience to cater to your specific requirements. Our aim is to provide exceptional support and exceed your expectations in every aspect of our service.

Contact us today to discuss your refractory materials needs in Angola and let us be your trusted supplier and partner.

In addition to our sales services, we also provide comprehensive quotations to help you plan and budget for your projects. Our experienced team is well-versed in the local market and can offer valuable insights and guidance to ensure that you make informed decisions.

Furthermore, our technical support team is always ready to assist you with any technical queries or challenges you may face. From installation guidance to troubleshooting, we are committed to ensuring that your projects run smoothly and successfully.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to source and supply a wide range of refractory materials, including those that may be hard to find in the local market. We strive to be your reliable partner for all your refractory materials procurement needs.

Whether you are involved in the steel, cement, glass, or any other industry, we have the knowledge and experience to cater to your specific requirements. Our aim is to provide exceptional support and exceed your expectations in every aspect of our service.

Contact us today to discuss your refractory materials needs in Angola and let us be your trusted supplier and partner.

Hot Search

- Monolithic Refractories in British

- Ceramic Fiber Products in Tuvalu

- Refractory Bricks in Fiji

- Raw Materials For Refractory in Kuwait

- Refractory Bricks in Oman

- Ceramic Fiber Products in Canada

- Raw Materials For Refractory in Benin

- Raw Materials For Refractory in Malta

- Ceramic Fiber Products in Maldives

- Raw Materials For Refractory in Indonesia