All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the history of aluminum profiles and their development over the years?

Aluminum profiles have a rich history dating back to the late 19th century. In 1886, the Hall-Héroult process was invented, allowing for the mass production of aluminum through the electrolysis of alumina. This breakthrough made aluminum more affordable and accessible for various applications.

The early use of aluminum profiles can be traced to the construction of the Eiffel Tower in 1889, where aluminum was used for structural components. However, it wasn't until the 20th century that aluminum profiles gained significant popularity and found widespread use in various industries.

During World War II, aluminum profiles became crucial for military aircraft production due to their lightweight yet strong properties. This led to further advancements in aluminum alloy compositions and extrusion techniques, making it possible to shape aluminum profiles into different forms and sizes.

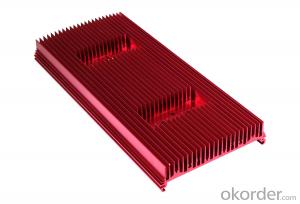

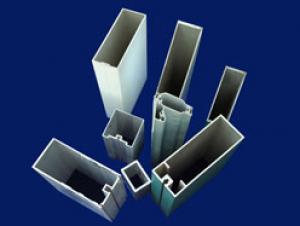

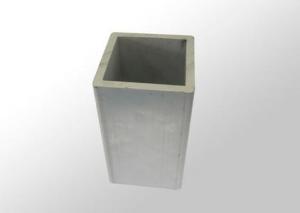

In the post-war era, aluminum profiles found applications in architecture, transportation, and consumer goods. Their versatility, durability, and corrosion resistance made them a preferred choice for window frames, door sills, automotive parts, and even furniture.

Over the years, advancements in extrusion technology, surface treatments, and alloy compositions have continued to enhance the performance and aesthetics of aluminum profiles. Today, aluminum profiles are widely used in construction, automotive, aerospace, and many other industries due to their lightweight nature, recyclability, and ability to be custom-designed for specific applications.

Overall, the history of aluminum profiles showcases a journey of innovation and evolution, driven by the need for lightweight, durable, and sustainable materials in various sectors.

How are aluminum profiles used in the automotive industry to reduce vehicle weight?

Aluminum profiles are used in the automotive industry to reduce vehicle weight by replacing heavier steel components. These profiles are lightweight yet strong, allowing for better fuel efficiency and improved handling. They are often used in the construction of car bodies, suspension systems, and engine components, contributing to overall weight reduction and increased performance.

How do you calculate the weight of aluminum profiles?

To calculate the weight of aluminum profiles, you need to multiply the density of aluminum (2.7 g/cm³) by the volume of the profile. The volume can be determined by measuring the length, width, and height of the profile and multiplying them together. Finally, multiply the volume by the density to obtain the weight of the aluminum profile.

Wholesale Aluminum Profiles from supplier in Albania

We are a Aluminum Profiles supplier serving the Albania, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Albania region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Albania. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Albania, we can also provide valuable experience for your projects.