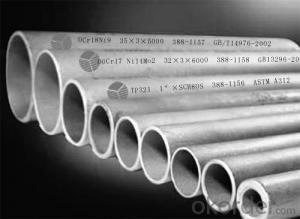

Stainless Steel Flex Pipe

Stainless Steel Flex Pipe Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Flex Pipe Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Flex Pipe supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Flex Pipe firm in China.Hot Products

FAQ

- What is lined with stainless steel?

- Stainless steel lining technology is a thin-walled stainless steel tube as a carrier for welding molding, the traction winch as the power, the stainless steel liner pipe from the end of the pipeline to be pulled to the other end. After the stainless steel pipe lining is inserted, it is punched, and the gap between the inner liner and the original pipe is grouted and solidified under the condition of holding pressure. A composite tube that is tightly bonded to the original pipe and has a smooth surface. So as to achieve strong pressure, impact resistance, corrosion resistance of the overall repair purposes, to extend the service life of the original pipe for more than fifty years.

- Yes, stainless steel pipes can be insulated with polystyrene. Polystyrene is a commonly used insulation material due to its excellent thermal insulation properties. It helps prevent heat loss or gain from the pipes and improves energy efficiency. Polystyrene insulation can easily be applied to stainless steel pipes using various methods such as pre-formed insulation jackets, spray foam insulation, or rigid foam board insulation. However, it is important to ensure that the insulation is properly installed and sealed to avoid any potential moisture issues or damage to the pipes.

- Indeed, polypropylene serves as an appropriate material for insulating stainless steel pipes. This is due to its remarkable thermal properties and minimal thermal conductivity. Polypropylene exhibits resistance against moisture, chemicals, and UV radiation, rendering it suitable for diverse applications. By implementing polypropylene insulation, the loss or gain of heat in stainless steel pipes can be averted, thereby enhancing energy efficiency and decreasing the likelihood of condensation or freezing. Consequently, it is imperative to guarantee the correct installation and compatibility of the polypropylene insulation with the particular stainless steel pipe in order to attain optimal performance and durability.

- Yes, stainless steel pipes can be used for steam applications. Stainless steel is known for its high temperature resistance and corrosion resistance, making it suitable for steam systems. It can withstand the high pressure and temperatures that steam applications require without deforming or corroding. Stainless steel pipes are also durable and have a long lifespan, making them a reliable choice for steam applications. Additionally, stainless steel pipes can be easily welded, ensuring a secure and leak-free steam system.

- To calculate the pipe length required for a specific application, you need to consider factors such as the flow rate, pressure drop, pipe material, and the type of fluid being transported. By using equations and formulas specific to fluid dynamics, you can determine the appropriate pipe length needed to achieve the desired flow and pressure conditions. Additionally, factors like pipe fittings, bends, and elbows also need to be taken into account when calculating the overall pipe length required.

- Indeed, it is possible to galvanize stainless steel pipes. Galvanization refers to the application of a safeguarding zinc coating on steel or iron to thwart the occurrence of rust. Although stainless steel already possesses a high level of resistance to corrosion, galvanization can serve as an extra layer of defense in specific situations. However, it is worth mentioning that galvanizing stainless steel pipes is not as prevalent as galvanizing carbon steel pipes since the innate corrosion resistance of stainless steel is generally satisfactory for most applications. Moreover, the process of galvanizing stainless steel can modify its visual appearance and may not be suitable for certain aesthetic prerequisites.

- Certainly! Stainless steel pipes are capable of being used in wastewater systems. Due to its high durability and resistance to corrosion, stainless steel is an appropriate material for various applications, including wastewater systems. The robust nature of stainless steel pipes enables them to withstand the harsh and corrosive properties of wastewater, preventing any potential leaks, cracks, or damages that could compromise the system's integrity. Furthermore, stainless steel pipes are easily cleanable, ensuring that hygiene standards are maintained within wastewater systems. Their long-lasting properties and resistance to rust also make them a cost-effective choice in the long term, as they necessitate less maintenance and replacement when compared to alternative materials. Overall, stainless steel pipes provide a dependable option for wastewater systems, guaranteeing efficient and secure wastewater disposal.

- Yes, stainless steel pipes can be coated or painted. Coating or painting stainless steel pipes can provide various benefits such as enhanced corrosion resistance, improved aesthetic appearance, and increased durability. However, it is important to note that proper surface preparation is crucial before applying any coating or paint to ensure adhesion and longevity. Additionally, it is recommended to use coatings or paints specifically designed for stainless steel to maintain its inherent qualities and prevent any potential issues such as flaking or peeling.