cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

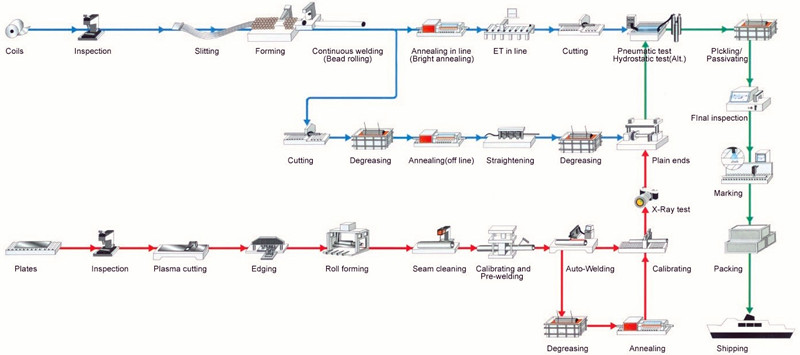

A series of photos

A series of pictures

- Q:Can stainless steel pipes be electroplated?

- Stainless steel pipes, unfortunately, do not have the ability to be electroplated. Electroplating is a technique that involves applying a layer of metal onto a conductive surface through the use of an electric current. Nevertheless, stainless steel is inherently corrosion-resistant because it contains chromium, which creates a protective layer on its surface. Consequently, electroplating is unnecessary for stainless steel pipes since they already possess the desired attributes of durability and corrosion resistance.

- Q:How do you test the quality of stainless steel pipes?

- To test the quality of stainless steel pipes, several methods can be used. 1. Visual Inspection: The first step is to visually inspect the pipes for any visible defects such as cracks, dents, or surface irregularities. This can be done by simply observing the pipes closely and checking for any abnormalities. 2. Dimensional Inspection: The dimensions of the stainless steel pipes should meet the specified requirements. This involves measuring the outer diameter, inner diameter, wall thickness, and length of the pipes using calibrated measuring instruments such as calipers or micrometers. 3. Chemical Composition Analysis: Stainless steel pipes should have a specific chemical composition to ensure corrosion resistance and durability. This can be determined by conducting a chemical composition analysis, which involves using techniques like spectroscopy or wet chemical analysis to check the presence and percentage of different elements in the steel. 4. Mechanical Properties Testing: Mechanical properties such as tensile strength, yield strength, and elongation are crucial indicators of the quality of stainless steel pipes. These properties can be tested through various methods including tensile testing, hardness testing, impact testing, or bending testing. These tests are performed according to relevant industry standards to ensure the pipes meet the required mechanical specifications. 5. Non-destructive Testing: Non-destructive testing methods like ultrasonic testing, X-ray inspection, or electromagnetic testing can be employed to detect any hidden defects or inconsistencies within the stainless steel pipes without causing any damage. These tests are useful in identifying flaws such as cracks, voids, or inclusions that may compromise the quality and performance of the pipes. 6. Corrosion Resistance Testing: Stainless steel pipes are known for their excellent corrosion resistance. To verify their resistance to corrosion, various tests like salt spray testing or exposure to harsh environments can be conducted. These tests simulate real-life conditions to evaluate the pipes' ability to resist corrosion and ensure their long-term durability. It is important to note that the specific testing methods and standards may vary depending on the industry or application requirements. Therefore, it is essential to refer to relevant standards and specifications while conducting quality tests on stainless steel pipes.

- Q:What is the weight of a stainless steel pipe?

- The weight of a stainless steel pipe depends on various factors such as its diameter, wall thickness, and length. Stainless steel pipes are generally denser than other materials due to their high iron and chromium content. To calculate the weight, one needs to know the specific dimensions of the pipe and consult a weight chart or use a formula. For example, the weight per foot of a stainless steel pipe can be calculated by multiplying the pipe's cross-sectional area (πr²) by its length and then multiplying it by the density of stainless steel.

- Q:How do you prevent stress corrosion cracking in stainless steel pipes?

- One way to prevent stress corrosion cracking in stainless steel pipes is to ensure proper material selection. Using stainless steel grades that are resistant to stress corrosion cracking, such as duplex or super duplex stainless steel, can significantly reduce the risk. Additionally, maintaining a suitable environment by controlling temperature, pH levels, and exposure to corrosive substances can also help prevent stress corrosion cracking. Regular inspection and maintenance, including cleaning and passivation, can further enhance the integrity and durability of stainless steel pipes, minimizing the chances of stress corrosion cracking.

- Q:Can stainless steel pipes be used for underground drainage?

- Yes, stainless steel pipes can be used for underground drainage. Stainless steel is highly resistant to corrosion, making it a suitable material for underground applications where moisture and chemical exposure are common. Additionally, stainless steel pipes offer durability and strength, ensuring long-lasting performance in underground drainage systems.

- Q:What is the difference between seamless and hot-expanded stainless steel pipes?

- Seamless and hot-expanded stainless steel pipes are two different types of manufacturing processes for producing stainless steel pipes. Seamless stainless steel pipes are made by piercing a solid billet of stainless steel and then rolling it into a pipe shape. This process does not involve any welding or joining of separate pieces, resulting in a seamless pipe. Seamless pipes are known for their uniformity and strength, as there are no weak points or potential leak paths in the pipe. They are generally more expensive to produce and are used in applications where high corrosion resistance and pressure handling are required, such as in the oil and gas industry or in high-pressure boilers. On the other hand, hot-expanded stainless steel pipes are made by heating a stainless steel pipe and expanding it to a larger diameter using a mandrel inside the pipe. This process creates a larger diameter pipe with a uniform wall thickness. Hot expansion is typically used to produce larger diameter pipes that are required for specific applications. The hot expansion process can improve the mechanical properties of the pipe, such as increased tensile strength and improved resistance to corrosion. These pipes are commonly used in industries such as petrochemical, power generation, and construction. In summary, the main difference between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes and the resulting properties of the pipes. Seamless pipes are made by rolling a solid billet, while hot-expanded pipes are created by heating and expanding an existing pipe. Seamless pipes are known for their strength and uniformity, while hot-expanded pipes are often used for larger diameter applications and can have improved mechanical properties.

- Q:How do you calculate the flow rate in stainless steel pipes?

- To calculate the flow rate in stainless steel pipes, you can use the principles of fluid dynamics and the properties of the fluid flowing through the pipe. There are several factors that should be taken into consideration: 1. Determine the diameter of the pipe: The diameter of the pipe will affect the flow rate since a larger diameter allows for a greater volume of fluid to pass through. 2. Determine the viscosity of the fluid: Viscosity refers to the resistance of a fluid to flow. Fluids with higher viscosity will flow more slowly, while fluids with lower viscosity will flow more quickly. 3. Calculate the pressure drop: The pressure drop across the pipe is an important factor in determining the flow rate. This can be calculated using pressure measurements at different points along the pipe. 4. Use the Reynolds number: The Reynolds number is a dimensionless quantity that combines the fluid velocity, density, viscosity, and pipe diameter. It helps determine whether the flow is laminar (smooth) or turbulent (chaotic). There are different equations to calculate the Reynolds number depending on the flow regime. 5. Apply the appropriate flow equation: Depending on the flow regime, you can use different equations to calculate the flow rate. For laminar flow, the Hagen-Poiseuille equation can be used. For turbulent flow, the Darcy-Weisbach equation or the Manning equation can be used. By considering these factors and applying the appropriate equations, you can calculate the flow rate in stainless steel pipes. It is important to note that these calculations provide an estimate and may not be exact due to various factors such as pipe roughness, fittings, and other obstructions in the pipe. Therefore, it is recommended to consult with a fluid dynamics expert or use specialized software for accurate calculations.

- Q:Can stainless steel pipes be used for swimming pool systems?

- Yes, stainless steel pipes can be used for swimming pool systems. Stainless steel is a popular choice for swimming pool piping due to its excellent corrosion resistance and durability. It is resistant to rust and can withstand exposure to chlorine, saltwater, and other chemicals commonly used in pool systems. Stainless steel pipes also have high strength, making them suitable for handling the pressure and flow of water in swimming pool systems. Additionally, stainless steel pipes are easy to clean and maintain, ensuring a long lifespan for the pool system.

- Q:What is the difference between annealed and pickled stainless steel pipes?

- Annealed stainless steel pipes are heat-treated to remove internal stresses, making them softer and more malleable. This process improves their machinability and allows for easier forming and welding. On the other hand, pickled stainless steel pipes undergo a chemical treatment (usually with an acid solution) to remove surface impurities and oxide layers. This process enhances the corrosion resistance of the pipes and provides a smooth, clean surface finish.

- Q:Can stainless steel pipes be used for both high and low-pressure applications?

- Stainless steel pipes possess the ability to serve in high and low-pressure scenarios. Stainless steel's reputation for its robustness, endurance, and corrosion resistance renders it apt for diverse pressure circumstances. It can endure high pressures unflinchingly, without any distortion or breakage, hence proving to be an optimal choice for high-pressure purposes such as oil and gas pipelines, chemical processing plants, and hydraulic systems. Furthermore, it can be employed for low-pressure applications such as plumbing systems and water supply lines. The adaptable nature of stainless steel pipes enables their usage across an extensive array of pressure conditions, which contributes to their popularity in numerous industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords