Kst Values For Common Dusts

Kst Values For Common Dusts Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Steel Mesh Panels For SaleKst Values For Common Dusts Supplier & Manufacturer from China

Okorder.com is a professional Kst Values For Common Dusts supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Kst Values For Common Dusts firm in China.Hot Products

FAQ

- What is the cold mounted board

- KT board is a PS foam sheet, the board is crisp, light, easy to degenerate, easy to process, and can be directly on the board screen printing, paint (need to detect paint adaptability) and inkjet, widely used in advertising, Decoration, culture and art and packaging. The use of advertising is used for product promotion information dissemination of the exhibition, display and notice with mounting liner, the other is a large number of applications used in a screen printing, especially for a wide range of unified publicity activities carried out. KT board from the current more mature production process can be divided into cold composite and thermal composite, these two different products produced by the corresponding product called (cold composite board) cold plate - commonly known as cold mounted board and (hot composite board Hot plate - the KT board. Cold plate production process, the first is the core foam: the raw material is PS particles, but because the cold plate is mostly single-layer board core, so to double foam, the first foam thickness is generally about 3.5mm, ripening After half a month, and then the second foam, the core into the device foam to 5.0-5.2mm or so, the second foam can be directly after the paste paste. And then paste the dough: dough the substrate is PVC, usually 0.08m-0.1mm, 0.9 × 2.4 small plates are mostly used 0.08-0.1mm dough, 1.2 × 2.4 large plate generally use 0.16mm dough to strengthen the board Stiffness, because the surface is PVC, the core is the PS material, so the choice must be neutral glue, glue in the dough and the core at the same time glue each other paste, paste to the plate hydraulic press (more than ten tons) squeeze, more than 24 hours Can be taken out trimming trim shipping. Yichang area commonly used cold plate is mainly 1.2 × 2.4 large board, 0.9 × 2.4 small board is now rarely seen on the market.

- its in a place i cannot get to without knocking down a wall and ceiling - is there anything i can pour down the drain to stop the leak at the joint - its a very small drip

- there,s nothing you can put in it to stop the leak. you might be able to shut the water off and run a new line.

- Can PVC be used for automatic painting?

- First, PVC can be used automatic painting, PVC sheet surface can be painted, but must be on the surface of the sheet after the hair (with sandpaper to play again) in order to make the film better "adhesion" in the plate surface, And it is best to use anti-ultraviolet paint. Second, if you need pvc board paint, it is best to find professionals to complete. According to the plate production quality, and cost integrated: 1. Suitable for painting of the plate, solid wood, blockboard, high-quality multi-layer plywood, aluminum-plastic plate; 2. Suitable for cold paste PVC are: medium and high density board, particleboard, multi-layer board, woodworking board; 3. Suitable for hot-melamine are: MDF, high-grade multi-layer plywood, high-grade blockboard; 4. Suitable for the film: the ordinary multi-layer board, MDF, particleboard; 5. Suitable for imitation paper: ordinary solid wood, smooth multi-layer board, blockboard; 6. posted fire board are: MDF, particleboard and so on.

- Pvc buckle board, installed smallpox, the specific steps, must be detailed, to DIY Kazakhstan

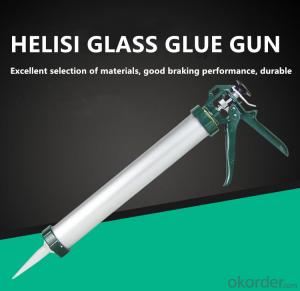

- Hello, the following began to hang pvc buckle board ceiling. Material; pvc buckle plate, pvc trim corner, card main dragon, deputy dragon Tools; impact drill, glass gun, glass glue (porcelain white) self-tapping screws, screwdriver, 6 PCT top burst, 8% impact drill, 6% screw, 6% nut, Start construction; first set a point in the porcelain wall, see the ceiling hanging high, and then hit the water, in the pvc trim corner sticking glass glue, and then stick in the flat water line, the angle and the outer corner is more trouble. And then side by side in the zeal hit 4 holes, (8% impact drill) installed 6% burst, remember to open the top. And then from the top of the ceiling to pvc trim angle, the height is 6% screw to cut the length of the cut in the 4 4 4 screw at one end of the twist nut, and now began to card on the main dragon, and then the deputy dragon Hanging out, so that the ceiling board ceiling out of the shelf.

- how to build cat cages out of PVC pipe?

- Pvc Cat Cage

- How to clean the kitchen ceiling pvc board What cleaning?

- Like to avoid the use of wood keel, and PVC board after a period of time easy to change color, aging or damage, sticky oil is difficult to clean. Therefore, the current open kitchen ceiling decoration generally use waterproof plaster board, aluminum plate, moisture board.

- Production of PVC foam board of raw materials are what ah? What is the role of ah?

- Stabilizer: In the PVC foam sheet production process, in order to make the material fully plasticized, the material temperature is higher; and the plate mold cross-section width, long runner, especially the crust foam sheet mold section is longer, In addition, the blowing agent in the decomposition process also produce decomposition heat, these factors require stabilizers must have sufficient thermal stability. In order to ensure product quality, long-term stable production.