Aluminium Sheets for Different Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

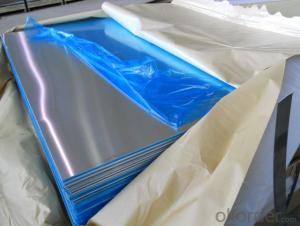

1.Structure of Aluminium Sheets for Different Curtain Walls Aluminum coils are widely used in curtain walls including solar energy curtain wall, unitized curtain wall, stick curtain wall, semi-unitized curtain wall, point-fixing curtain wall, full-glass curtain wall, double-skinned energy-saving curtain wall, steel structure curtain wall, etc. Aluminium Coils for Different Curtain Walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Sheets for Different Curtain Walls •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Sheets for Different Curtain Walls Images 4.Specification of Aluminium Sheets for Different Curtain Walls Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5. FAQ A.What about inspections to guarantee quality? For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium sheets? We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Can aluminum sheets be bent without cracking?

- Indeed, aluminum sheets possess the remarkable quality of being bendable without succumbing to cracks. This is due to aluminum's exceptional malleability and ductility, enabling it to be effortlessly molded and reshaped without experiencing fractures. Nevertheless, the success of bending aluminum sheets without cracks hinges upon various factors, including the sheet's thickness, the type and grade of aluminum employed, and the particular bending method employed. To guarantee its integrity and prevent cracks, it is crucial to utilize appropriate tools and techniques when embarking upon the task of bending aluminum.

- Q:How do aluminum sheets perform in terms of vibration damping?

- Aluminum sheets possess exceptional vibration damping properties, renowned for their ability to effectively absorb and dissipate vibrations. These sheets, with their high density and stiffness, are capable of reducing both the amplitude and duration of vibrations. Consequently, aluminum sheets are deemed highly suitable for applications demanding vibration control, particularly in the aerospace and automotive sectors. Moreover, the lightweight nature of aluminum enables effortless installation and maneuverability, rendering it the preferred choice for vibration damping solutions.

- Q:... initial temperature of the water or the initial temperature of the aluminum? Why?

- Let's say the aluminum starts out at a higher temperature than the water. The aluminum cools down by 1°C, which means it loses energy (Q = mcΔT, where ΔT = 1°C). That energy goes to the water, warming it up. Since Q is the same for both water and aluminum, and m is the same for both, all that matters is the heat capacity c. Water has a higher heat capacity than aluminum, so for the same Q it must have a smaller ΔT. This process continues until both have reached the same T. From the above paragraph, you should be able to figure out if the final T is closer to the initial water temp or the original aluminum temp.

- Q:How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly referred to as the gauge, and it is measured in inches or millimeters. The sheet's width and length are also specified in either inches or millimeters. To measure the thickness of an aluminum sheet, a gauge is used. The gauge is a standardized measurement tool that determines the sheet's thickness. The lower the gauge number, the thicker the sheet. For example, a 10-gauge aluminum sheet is thicker than a 16-gauge sheet. The width and length of an aluminum sheet are typically measured in inches or millimeters. The width refers to the horizontal measurement of the sheet, while the length refers to the vertical measurement. These dimensions are crucial in determining the sheet's size and suitability for specific applications. In addition to the gauge, width, and length, aluminum sheets may also be specified based on their alloy composition or temper. The alloy composition indicates the specific combination of metals present in the sheet, such as aluminum-magnesium, aluminum-zinc, or aluminum-copper alloys. The temper refers to the heat treatment process the sheet has undergone, which affects its mechanical properties, such as hardness and flexibility. Overall, aluminum sheets are measured and specified by their thickness (gauge), width, and length. These measurements, along with additional specifications like alloy composition and temper, help ensure the appropriate selection and use of aluminum sheets for various applications in industries such as construction, automotive, aerospace, and more.

- Q:Are 101 aluminum sheets suitable for marine environments?

- Indeed, marine environments are indeed suitable for 101 aluminum sheets. Recognized for its exceptional corrosion resistance, 101 aluminum is a high-strength alloy that proves to be perfect for marine applications. It can endure the harsh circumstances of saltwater, including exposure to salt spray and water immersion, without undergoing corrosion or deterioration. Furthermore, 101 aluminum possesses commendable weldability and formability, enabling it to be effortlessly shaped into a multitude of marine components like boat hulls, decks, and equipment. The strength, durability, and corrosion resistance of 101 aluminum sheets establish them as a dependable option for marine environments.

- Q:Can aluminum sheets be used for reflectors?

- Yes, aluminum sheets can be used for reflectors. Aluminum is widely known for its excellent reflectivity properties, making it an ideal material for reflectors in various applications. Its high reflectivity allows it to efficiently redirect and reflect light, making it suitable for use in lighting fixtures, solar panels, telescopes, and other devices that require accurate and efficient reflection of light. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it a practical choice for reflectors that need to withstand harsh environmental conditions.

- Q:Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be bent or formed into different shapes through processes such as bending, rolling, or pressing, due to its malleability and ductility.

- Q:Can aluminum sheets be used for flooring?

- Yes, aluminum sheets can be used for flooring. Aluminum is a lightweight and durable material that can withstand heavy foot traffic and is resistant to corrosion. It is commonly used for industrial flooring, outdoor decks, and transportation platforms.

- Q:Can 101 aluminum sheets be anodized?

- Indeed, the anodization of 101 aluminum sheets is feasible. Anodization, which entails the formation of a safeguarding oxide layer on the aluminum's surface, enhances its resilience against corrosion and overall durability. This technique can be employed on different aluminum grades, including 101, to achieve desired finishes and offer added protection. The anodization process can be executed through diverse methods such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on specific needs and desired outcomes. Consequently, it is assured that 101 aluminum sheets can undergo anodization procedures.

- Q:Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheets for Different Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords