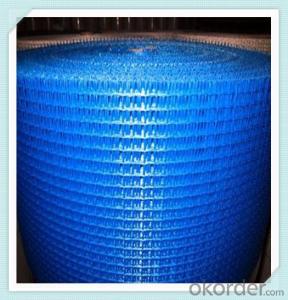

Fiberglass Cloth Roll

Fiberglass Cloth Roll Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiberglass Sheets For Roofing Track Lights For Kitchen Ceiling Lights For Kitchen Ceiling Lights For Fall Ceiling Spotlight For Ceiling 5 Blade Ceiling Fan With Light 12X12 Ceiling Tiles With HolesHot Searches

Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Cost Of Concrete Tile Roof Roof Insulation Price Artificial Slate Roof Tiles Price Ceiling Fan Lowest Price Tesla Solar Roof Inverter Types Of Flat Roof Coverings Stone Wall Tiles Cost Company Office Design Ceramic Roof Tiles Cost Metal Roof Tiles Prices Cement Roof Tile Manufacturers Clay Roof Tile Manufacturers Synthetic Roof Tiles Cost Roof Clay Tiles Prices Interlocking Roof Tiles Prices 30 Year Roof Shingles PricesFiberglass Cloth Roll Supplier & Manufacturer from China

Okorder.com is a professional Fiberglass Cloth Roll supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Fiberglass Cloth Roll firm in China.Hot Products

FAQ

- There are several different weaving patterns available for fiberglass fabric, each with its own unique characteristics and applications. 1. Plain Weave: This is the most basic and commonly used weaving pattern for fiberglass fabric. It consists of a simple over-and-under interlacing of warp and weft yarns, creating a balanced and uniform fabric structure. Plain weave fiberglass fabric offers good strength, dimensional stability, and is suitable for a wide range of applications. 2. Twill Weave: Twill weave creates a diagonal pattern on the fabric surface, achieved by passing the weft yarn over multiple warp yarns before going under. This weaving pattern enhances the fabric's drapability, flexibility, and allows for better conformability to complex shapes. Twill weave fiberglass fabric is often used in applications where flexibility and durability are required, such as in the aerospace and automotive industries. 3. Satin Weave: Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and lustrous surface with less crimp and higher yarn density. Satin weave fiberglass fabric offers excellent drapeability, high strength-to-weight ratio, and is commonly used in applications that require a high-quality surface finish, such as marine and sporting goods industries. 4. Leno Weave: Leno weave is a unique pattern where the warp yarns are twisted around each other, creating an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric is often used in applications such as filtration, reinforcement in composites, and as a base fabric for laminates. 5. Jacquard Weave: Jacquard weave is a complex pattern created by individually controlling each warp yarn. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. Overall, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each weaving pattern offers unique characteristics and advantages, allowing for a wide range of possibilities in utilizing fiberglass fabric across various industries.

- Indeed, insulation in HVAC systems can utilize fiberglass fabrics. The preference for fiberglass as an insulation material in HVAC systems stems from its exceptional thermal characteristics. Its low thermal conductivity enables it to effectively impede heat transfer. Fiberglass fabrics are typically employed to encase air ducts, pipes, and other components in HVAC systems to prevent heat loss or gain. Aside from its thermal efficiency, fiberglass fabrics possess other advantageous properties that render them suitable for insulation purposes. They are lightweight, flexible, and simple to install, making them a convenient option for HVAC insulation. Additionally, fiberglass fabrics exhibit resistance to moisture, mold, and mildew, thus contributing to the maintenance of satisfactory indoor air quality. Moreover, fiberglass fabrics boast outstanding fire-resistant qualities. They are non-combustible and do not emit toxic gases when exposed to high temperatures. Consequently, fiberglass fabrics constitute a safe choice for insulation in HVAC systems. All in all, the utilization of fiberglass fabrics for insulation in HVAC systems proves to be highly effective due to their thermal efficiency, ease of installation, resistance to moisture, and fire safety.

- Yes, fiberglass fabric can be used for insulation in breweries. It is a commonly used material due to its excellent thermal insulation properties, fire resistance, and durability. It helps maintain the desired temperature and prevents heat loss, making it suitable for insulating tanks, pipes, and other equipment in breweries.

- Indeed, high-temperature environments can accommodate the utilization of fiberglass fabrics. The exceptional resistance to heat possessed by fiberglass renders it an optimal option for purposes necessitating insulation or safeguarding against elevated temperatures. Its structural integrity and performance remain intact even when confronted with temperatures as high as 1000°F (538°C). Industries such as aerospace, automotive, and manufacturing frequently employ these fabrics due to the prevalence of high temperatures in their operations. Moreover, fiberglass fabrics exhibit characteristics of being lightweight, durable, and possessing commendable thermal conductivity, thereby establishing themselves as an ideal material for high-temperature surroundings.

- Yes, fiberglass fabric is suitable for use in aerospace interiors. Fiberglass fabric is known for its excellent strength-to-weight ratio and fire resistance, making it an ideal material for various applications in the aerospace industry. It is commonly used in the construction of aircraft interiors, including walls, ceilings, seats, and insulation. One of the primary reasons fiberglass fabric is preferred in aerospace interiors is its high strength. It offers exceptional durability and can withstand the rigorous conditions and vibrations experienced during flights. Additionally, its lightweight nature helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency. Moreover, fiberglass fabric is inherently fire-resistant, which is crucial for ensuring the safety of passengers and crew members. In the event of a fire, fiberglass fabric will not ignite or contribute to the spread of flames, providing valuable time for evacuation and minimizing the risk of a catastrophic incident. Furthermore, fiberglass fabric is highly versatile and can be easily molded and shaped to fit the specific design requirements of aerospace interiors. It can be used as a structural material, providing stiffness and support, or as a decorative element, enhancing the aesthetic appeal of the cabin. In summary, fiberglass fabric offers numerous advantages that make it suitable for use in aerospace interiors. Its strength, lightweight nature, fire resistance, and versatility make it an excellent choice for ensuring the safety, durability, and functionality of aircraft cabins.

- Fiberglass fabric exhibits exceptional performance in cryogenic applications thanks to its unique properties. The impact of cryogenic temperatures on materials can be significant, but fiberglass fabric stands out with its excellent thermal insulation and low thermal conductivity, making it an ideal choice for use in cryogenic environments. One of the main advantages of fiberglass fabric in cryogenic applications lies in its ability to withstand extremely low temperatures without compromising its structural integrity. It possesses a high melting point and can endure thermal stress, ensuring its durability and reliability even under harsh conditions. This makes fiberglass fabric suitable for applications such as cryogenic storage tanks, pipelines, and equipment handling liquefied gases including nitrogen, oxygen, and LNG (Liquefied Natural Gas). Furthermore, fiberglass fabric demonstrates minimal thermal expansion, meaning it remains relatively stable when exposed to extreme temperature changes. This property is crucial in cryogenic applications as it helps prevent leaks or cracks that could compromise the system's integrity. Moreover, fiberglass fabric is non-corrosive and resistant to chemicals, which makes it suitable for use in cryogenic environments where exposure to potentially corrosive substances is common. It exhibits little to no reaction with most cryogenic fluids, ensuring the fabric remains intact and does not degrade over time. Another significant aspect is fiberglass fabric's excellent electrical insulation properties. Given that cryogenic applications often involve the handling of electrical components, utilizing fiberglass fabric as an insulating material helps prevent issues related to electrical conductivity that may arise due to temperature fluctuations. Overall, fiberglass fabric excels in cryogenic applications due to its thermal insulation, low thermal conductivity, high melting point, minimal thermal expansion, chemical resistance, and electrical insulation properties. These characteristics make it a reliable and durable material for various cryogenic systems and equipment.

- Yes, fiberglass fabric can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion. This typically involves cleaning the fabric to remove any dirt, dust, or oils, and then applying a primer specifically designed for use on fiberglass surfaces. Once the primer has dried, you can proceed to paint the fiberglass fabric with a suitable paint. It is important to use a paint that is compatible with the type of fiberglass fabric you are working with, as well as one that is designed for the specific application you have in mind (e.g., indoor or outdoor use). Additionally, it is recommended to use multiple thin coats of paint rather than one thick coat to achieve the best results.

- How to distinguish carbon fishing rod?

- Glass steel rod diameter, quality, more clumsy. Carbon rod light, very straight, small diameter, small and exquisite, the paint is mainly transparent or translucent paint, can see the rod material.