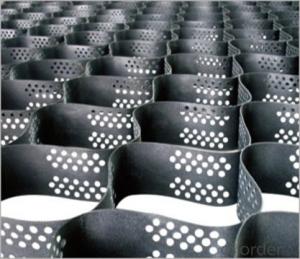

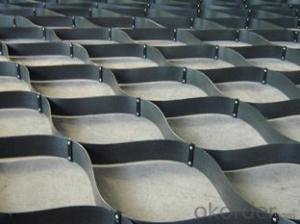

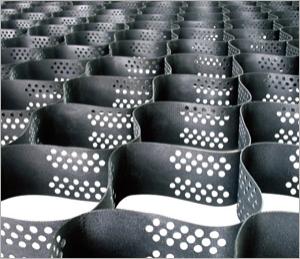

Smooth Textured Perforated Plastic HDPE Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Smooth Textured Perforated Plastic HDPE Geocell

HDPE Geocell is made of a new type of high strength geosynthetics, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 or ASTM D implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation. Easily folded and convenient for transportation. When be in construction, the geocell can be pull into a network and launched into a three-dimensional honeycomb grid. As it filled in sol, macadam, concrete or other granular materials, constituted to be a construction which has strong sidewise restraint and high rate of stiffness.

Main Features of Smooth Textured Perforated Plastic HDPE Geocell

1),Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

2),Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

3),Size is relatively stable, change the height and welding distance can meet the needs of different projects.

4),Retractile, easy to transport.

5),Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

6),Can be used repeatedly

Specifications of Smooth Textured Perforated Plastic HDPE Geocell

Sheet Thickness, mm | 1.2±0.1/1.7±0.1 | |||

Bonded Ranges,mm | 330±2.5~800±2.5 | |||

Cell Depth,mm | 50,75,100,100,150,200,250 | |||

Properties | Test Method | Value | ||

Material | HDPE | |||

Standard color | Black/Green | |||

Surface | Smooth/Textured | |||

Sheet Thickness, mm | ASTM D5199 | 1.2±0.1/1.7±0.1 | ||

Density, g/cm3 | ASTM D792 | >0.94 | ||

Carbon Black Content,% | ASTM D1603 | >2.0 | ||

Low Temperature Brittleness,C | ASTM D746 | <-77< span=""> | ||

Environment Stress Crack Resistance,hours | ASTM D1693 | >4000 | ||

Seam Peel Strength,N/100mm depth cell | COE GL-86-19 | 1000~1450 | ||

Seam Hang Strength,days | HKCTM | Per 100mm seam shall sustain 72.5kg weight for at least 7 days,undergoing the variances from room temperature to 53°C on one hour cycle | ||

Applications of Smooth Textured Perforated Plastic HDPE Geocell

1). To stable the roadbed of railway.

2). To stable the roadbed of highway.

3). To bear the load of dike or retaining wall.

4). To the imporement of shallow river way.

5). To support the pipeline and sewer.

6). For the prevention of landslide by using geocell as a heavy-duty hybrid force retaining wall.

7). To be used as independent wall, wharf and breakwater, etc.

8). For the desert, beaches and the riverbed, the river bank's regulation.

IMages of Smooth Textured Perforated Plastic HDPE Geocell

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q:What are the advantages of using geocells in green infrastructure?

- Geocells offer several advantages when used in green infrastructure. Firstly, they provide effective erosion control by preventing soil movement and retaining sediments, thus promoting the stability of slopes and preventing soil erosion. Secondly, geocells enhance the load-bearing capacity of soil, enabling the construction of stronger and more durable green infrastructure systems such as green roofs, permeable pavements, and retaining walls. Additionally, geocells promote vegetation growth by providing a stable and nutrient-rich environment for plant roots. This helps in creating sustainable and aesthetically pleasing green spaces. Lastly, geocells are cost-effective and relatively easy to install, making them a practical choice for green infrastructure projects.

- Q:Are geocells resistant to punctures and tears?

- Yes, geocells are typically designed to be resistant to punctures and tears due to their strong and durable materials. They are often made of high-density polyethylene (HDPE) which provides excellent puncture resistance and tear strength, making them suitable for various applications in civil engineering and soil stabilization projects.

- Q:Are geocells suitable for mining applications?

- Yes, geocells are suitable for mining applications. Geocells provide a stable and strong support system for mining operations, helping to prevent soil erosion and stabilize slopes. They can also be used to create access roads and platforms for heavy equipment. Geocells are cost-effective, easy to install, and have a long lifespan, making them a practical solution for mining applications.

- Q:How do geocells reduce vertical settlement?

- Geocells reduce vertical settlement by providing a stable and reinforced foundation for soils. The interconnected cells confine and distribute the load, increasing the bearing capacity of the soil and minimizing the potential for settlement.

- Q:Can geocells be used in mine tailings storage facilities?

- Yes, geocells can be used in mine tailings storage facilities. Geocells are a versatile and effective solution for stabilizing and reinforcing soil in various applications, including mine tailings storage facilities. They provide containment and erosion control by confining and stabilizing the tailings, preventing soil erosion and promoting efficient drainage. Additionally, geocells can enhance the structural integrity and stability of the storage facility, ensuring safe and long-term storage of mine tailings.

- Q:How do geocells enhance the performance of unpaved roads?

- Geocells enhance the performance of unpaved roads by providing structural support and confinement to the base materials. They prevent lateral spreading of the aggregate, improve load distribution, and increase the overall stability and strength of the road. Additionally, geocells reduce surface rutting, control erosion, and enhance the longevity of the unpaved road by withstanding heavy traffic loads and environmental conditions.

- Q:Can geocells be used in slope stabilization projects?

- Yes, geocells can be used in slope stabilization projects. Geocells are three-dimensional honeycomb-like structures made from high-strength materials, such as geotextiles or geogrids. They are commonly used to provide soil erosion control and slope stabilization in various civil engineering projects. Geocells can be filled with soil or aggregate material, creating a stable and reinforced structure that helps prevent soil erosion and slope failure.

- Q:Are geocells suitable for golf course construction?

- Yes, geocells are suitable for golf course construction. Geocells provide stability and erosion control to the soil, allowing for better turf quality and preventing soil movement. Additionally, geocells can be easily installed and are cost-effective, making them a viable option for golf course construction projects.

- Q:How do geocells improve subgrade stability?

- Geocells improve subgrade stability by confining and reinforcing the soil, creating a more stable and load-bearing foundation. The geocell structure prevents lateral spreading of the soil particles, increasing its shear strength and reducing settlement. Additionally, the cells distribute the applied load over a larger area, reducing the pressure on the subgrade and minimizing the risk of deformation or failure.

- Q:Can geocells be used in mining tailings management?

- Yes, geocells can be used in mining tailings management. Geocells are cellular confinement systems made of high-density polyethylene (HDPE) that can be filled with various materials, including tailings. They provide stability and reinforcement to the tailings, preventing erosion and controlling surface water runoff. Geocells also improve the consolidation and compaction of tailings, reducing the risk of slope failure and enhancing the overall stability of the tailings storage facility. Additionally, geocells can be easily installed and are cost-effective, making them a suitable solution for mining tailings management.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Smooth Textured Perforated Plastic HDPE Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords