Geocell of Enhanced for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocell of Enhanced for Architectural Engineering

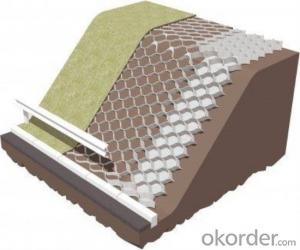

Description Of Geocell of Enhanced for Architectural Engineering

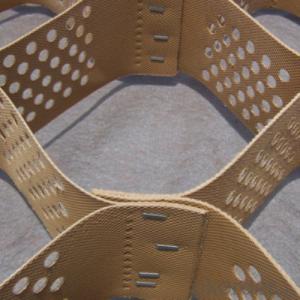

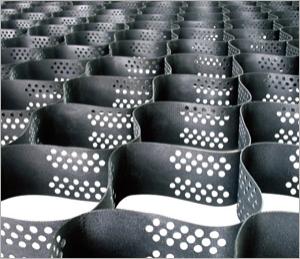

Geocell is three-dimensional network structure, which is made up of HDPE sheet material

Main Features of Geocell of Enhanced for Architectural Engineering

1, with retractile, transportation can be shrunk and stacked, the construction can be a Lacheng mesh, fill in the dirt, gravel, concrete and other loose material, with strong lateral restrictions and the stiffness of the structure.

2, light material, abrasion resistance, stable chemical properties, photooxidation aging, acid and alkali, applicable to different soil and desert soil conditions.

Applications of Geocell of Enhanced for Architectural Engineering

1, for the stability of highway, railway roadbed.

2, used to bear the weight of the embankment and shallow water treatment.

3, used to prevent the landslide and the load of the gravity of the hybrid retaining wall.

IMages of Geocell of Enhanced for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:How do geocells reduce the need for geogrid reinforcement?

- Geocells reduce the need for geogrid reinforcement by providing a three-dimensional structure that confines and stabilizes granular materials, such as soil or aggregate. This confinement enhances the load-bearing capacity of the material, reducing the lateral spreading and vertical settlement. As a result, geocells limit the movement and deformation of the granular fill, minimizing the stress on the underlying geogrid reinforcement and reducing the overall need for it.

- Q:Can geocells be used for seawall construction?

- Yes, geocells can be used for seawall construction. Geocells are three-dimensional cellular confinement systems made of high-density polyethylene materials that can be filled with soil, gravel, or concrete. These cells provide stability and erosion control, making them suitable for reinforcing seawalls and protecting coastal areas from wave action and erosion.

- Q:How do geocells enhance soil fertility?

- Geocells enhance soil fertility by preventing soil erosion, promoting better water retention, and providing a stable environment for plant roots to grow. Additionally, the structure of geocells allows for the efficient distribution of nutrients and organic matter, leading to improved soil quality and ultimately enhancing fertility.

- Q:How do geocells help with load-bearing capacity on soft soil?

- Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) that are filled with soil, gravel, or other infill materials. When placed on soft soil, geocells provide a stable and reinforced foundation by confining and distributing the load over a wider area. The interconnected cells prevent lateral spreading of the infill material, increasing its shear strength and overall load-bearing capacity. This confinement effect reduces settlement and prevents soil deformation, making geocells an effective solution for enhancing load-bearing capacity on soft soil.

- Q:Can geocells be used in channel protection projects?

- Yes, geocells can be used in channel protection projects. Geocells are a form of geosynthetic material that can be filled with soil, concrete, or other granular materials to create a stable and erosion-resistant structure. They are commonly used in channel protection projects to prevent erosion, stabilize slopes, and provide reinforcement. Geocells can effectively retain and confine soil, preventing it from being carried away by water flow and helping to maintain the integrity of the channel.

- Q:What is the cost-effectiveness of using geocells?

- The cost-effectiveness of using geocells can vary depending on the specific project and its requirements. However, in general, geocells offer a highly cost-effective solution for various applications. By providing stabilization and reinforcement to soil, geocells reduce the need for expensive excavation, additional materials, and maintenance. They also contribute to the longevity and durability of infrastructure, resulting in long-term cost savings. Additionally, geocells are easy to install and require minimal labor, further enhancing their cost-effectiveness.

- Q:Can geocells be used for pipeline protection?

- Yes, geocells can be used for pipeline protection. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene (HDPE) or other materials. They can be filled with soil, gravel, or other materials to create a stable and protective layer around pipelines. The geocells provide excellent load distribution, erosion control, and slope stability, which helps in safeguarding pipelines from external forces and environmental factors. Additionally, geocells also offer easy installation, cost-effectiveness, and long-term durability, making them a suitable solution for pipeline protection.

- Q:Can geocells be used for wetland rehabilitation?

- Yes, geocells can be used for wetland rehabilitation. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) material. They provide stability and support to soil and vegetation, which is crucial for wetland rehabilitation. Geocells help prevent erosion and enhance the growth of wetland vegetation by retaining water and nutrients, creating a suitable environment for wetland species to thrive. They also offer protection against wave action and can be easily filled with soil, allowing for the establishment of wetland plants. Overall, geocells are an effective and sustainable solution for wetland rehabilitation projects.

- Q:What are the advantages of using geocells in land reclamation?

- There are several advantages of using geocells in land reclamation. Firstly, geocells provide excellent erosion control and slope stabilization, preventing soil erosion and loss, especially in areas prone to heavy rainfall or strong currents. Secondly, geocells enhance the load-bearing capacity of the reclaimed land, allowing it to support heavy structures and infrastructure development. Additionally, geocells promote vegetation growth by creating a stable environment for plant roots, aiding in the overall ecological restoration of the reclaimed area. Overall, the use of geocells in land reclamation offers cost-effective and sustainable solutions, ensuring long-term stability and functionality of the reclaimed land.

- Q:What are the installation methods for geocells?

- The installation methods for geocells typically involve the following steps: 1. Site preparation: This includes clearing the area of any debris or vegetation and ensuring a smooth and level surface. 2. Base preparation: The base layer is prepared by compacting the soil or aggregate material to provide a stable foundation. 3. Geocell placement: The geocells are unfolded and laid out on the prepared base, ensuring they are properly aligned and connected. 4. Connection: The geocell panels are connected using the provided fasteners or connectors to create a continuous cellular structure. 5. Fill material placement: The geocells are filled with the desired infill material, such as sand, gravel, or soil. 6. Compaction: The infill material is compacted using appropriate compaction equipment to achieve the desired level of stability. 7. Surface finishing: The final step involves adding a top layer, such as grass or gravel, to provide a finished surface as per the project requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geocell of Enhanced for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords