Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

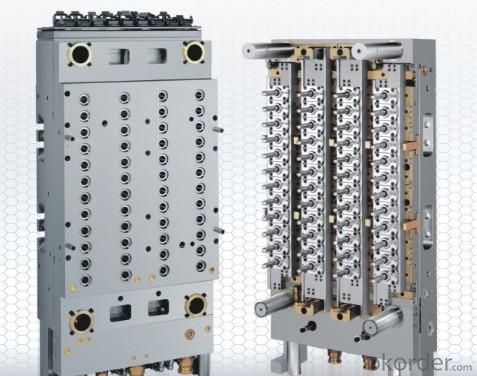

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

PET Preform Injection Molding from 1-cavity for wide mouth jar and gallon bottle perform up to 72-carrow neck perform mold; Tube blank is designed with the help of computer, which surely contributes to the increasing of yield of bottle;

Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independently to ensure low decentration of product;

Core and cavity are made of special mold steel after preheating treatment in the original factory in Sweden. Individual tempera-ture control of each cavity;

Lip cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The excellent hot runner design assures uniform heating and improves greatly of the plastic product quality;

No cutting of gate is employed to reduce the labor intensity;

Standard inter-changeable mold components;

The life of mold is more than 3 million times.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:The application of hydraulic cylinder in mould

- There are a few moulds that need to be pumped into the core, embedded, and unmoulded, most of which are used in hydraulic cylinders. There are some special molds that can be opened for material or material. There are also molds that can be used alternately, and also used in hydraulic cylinders. In the design of the mould, it is usually involved in a short range of linear motion, if the device is using a hydraulic system, the designers mostly use hydraulic cylinder devices.

- Q:The effect of mould preheating and several methods of preheating

- In order to protect the mould and improve the efficiency of the mould, it is necessary to keep the mould working in a certain temperature range as much as possible. If the mould no preheating, on the other hand, due to the mold temperature is low, it is easy to cause molding difficult, mucous membrane, the casting defects such as cracks, on the other hand, due to the mold temperature change is too big, hot and cold stress is very big, it is easy to mold damage, severe cases, may cause mould crack. Therefore, pre-heating is very important. According to the heating method, it can be divided into electric heating, natural (coal) gas heating and temperature heating. 1) electric heating: the heat tube is mainly heated by heat tube, which is clean and convenient to use. The drawback is that the thermal radiation is small. Die casting die is not adopted normally.

- Q:What is the manufacturing of mould materials

- You're talking about the industry that makes moulds. It is the metallurgical industry that makes mould material. From steelmaking to forging and rolling, it also belongs to heavy industry.

- Q:The stamping dies at the Angle of 90 degrees, the Angle is big or small how to repair.

- The recommended answer is quite different. Bending 90 degrees is supposed to have both internal and external conditions. The inside is less than 90 degrees, and the outside is greater than 90 degrees. This is the question of the gap and the rebound. This is in the normal model domain. General modulators and mold engineers know how to handle it. R and not R also affect this. In the case of the block under zero, the probability of a general Angle is reduced. But absolute zero is bad, can cause product scratches serious. Typically, the master moduler will be a little bit more angular, and if you do a zero, he will also get around R0.2. The solution to this problem is one packet of R processing. Adjust the bending clearance. 3 below the forming block. The moulding male is left straight after two to 3 degrees. Adjust bending clearance and so on. This is the basic problem of stamping die! I didn't elaborate on what to do, but if you were doing molds, according to the ones I was talking about, it would be easy enough to fix the problem. There are several other forms of prototyping. Each has its own merits. You know, it's not a good idea.

- Q:What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q:Introduction to mould design and manufacturing

- Having the necessary natural science, social science and management scientific knowledge; Knowledge of computer knowledge, necessary network knowledge, common software knowledge; Basic knowledge of mechanical knowledge; The basic knowledge of mechanical design theory, mould material and forming process, mould design and manufacturing expertise of this major. Knowledge of mould CAD/CAM. Basic knowledge of mould maintenance is necessary. Have certain self-study ability; Have the tooling design, process implementation, technical management capability; Have the ability of machining and programming of mould control; With injection mould, stamping mould design and manufacturing capacity; It has the ability of the working ability of the fitter, the mould repair ability; Good computer base application and computer aided design manufacturing and management capability; Ability to design and process mould design with CAD/CAM software. Good verbal, verbal and interpersonal skills.

- Q:What do you mean by the side of the plastic mould

- The division of heaven and earth is on the injection molding machine, the mould is on the injection molding machine, the upper side is the sky side, the lower side is the ground side One, on the side of the operator's operation, is called the operation side, and the other side is a side that deviates from the operator's side, which is called non-operating side or back 2, water in and out generally cannot be done on the operating side, for safety (some of the moulding hot water, if the detonation tube can burn the person) and the operator is convenient; The waterway is generally in the non-operational side, followed by the ground; It is also not advisable to use water in and out of the water, because if there is a leak, it will flow to the mold section and increase the injection rate. Inevitably, the water will flow through the channels through the channels

- Q:What kind of mold do you have?

- Die mold Die casting, hot chamber die casting machine with vertical cold chamber die casting, die casting machine with I type cold chamber die casting, die casting machine with full vertical die casting, die casting machine with non-ferrous metals (zinc, aluminum, copper, magnesium alloy die-casting, black metal die-casting mould Non-ferrous metal and black metal pressure casting process 4 Forging die Die forging and large press, forging die, forging die, roll forging die, etc. All kinds of fastener cold heading die, extrusion die, drawing die, liquid forging die etc Metal parts are formed and are pressed and compressed

- Q:In die mold, is it better to use UG or PROE? That's a quick one. Is it convenient?

- UG is a hybrid model that can be partially parameterized (and, of course, fully parameterized), which is good for the model update. PTC is completely parameterized, edit update small design (home appliances), large (planes, cars), however, does not crash, the refresh time will affect the designer's idea. Comparison 9: talk about the conversion of format! UG core PARASOLID is generally supported by more than three dimensional software! Only the PROE insist The most simple! The most commonly used software is MASTERCAM, which can only be turned through raw IGES or STEP

- Q:What are the advantages of using a hot runner?

- Mould at first using cold gate type products take material valve, sometimes forgotten to disc molding material not to say every mould produce secondary material is the material valve, hot runner after solved this problem, reduce secondary molding material directly, reduce labor workers parts, but that time has its drawbacks as well as the hot runner is uncontrolled, namely can't control the quantity of each point into the glue, along with the technical improvement on the current hot runner is mostly in the use of needle valve type, Kong Shi time controller is used to control each needle valve into the adhesive time for technology transfer machine save trouble is much,,,, adopt to adopt

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches