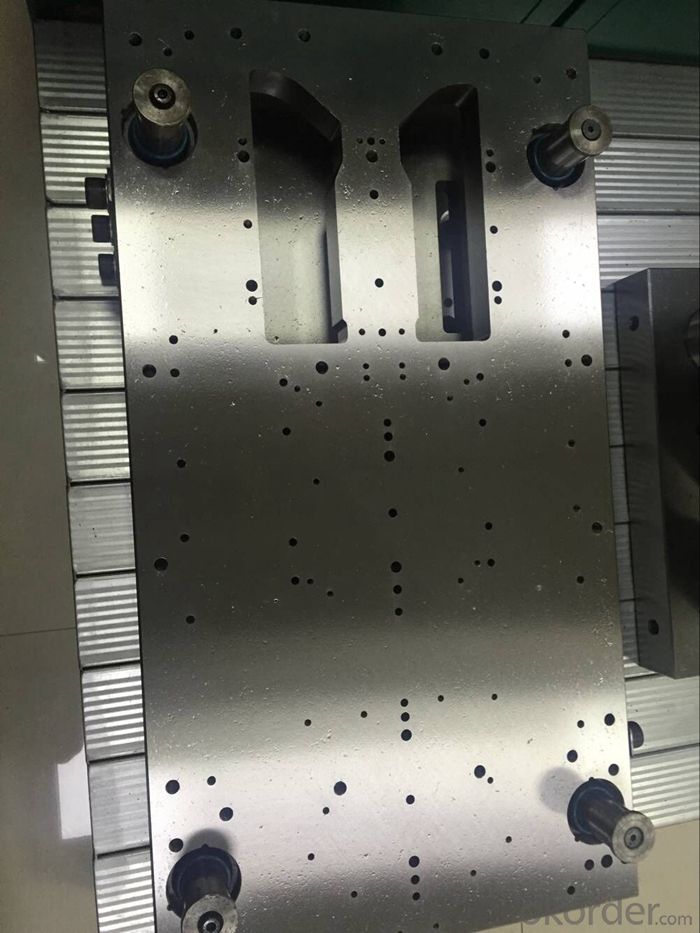

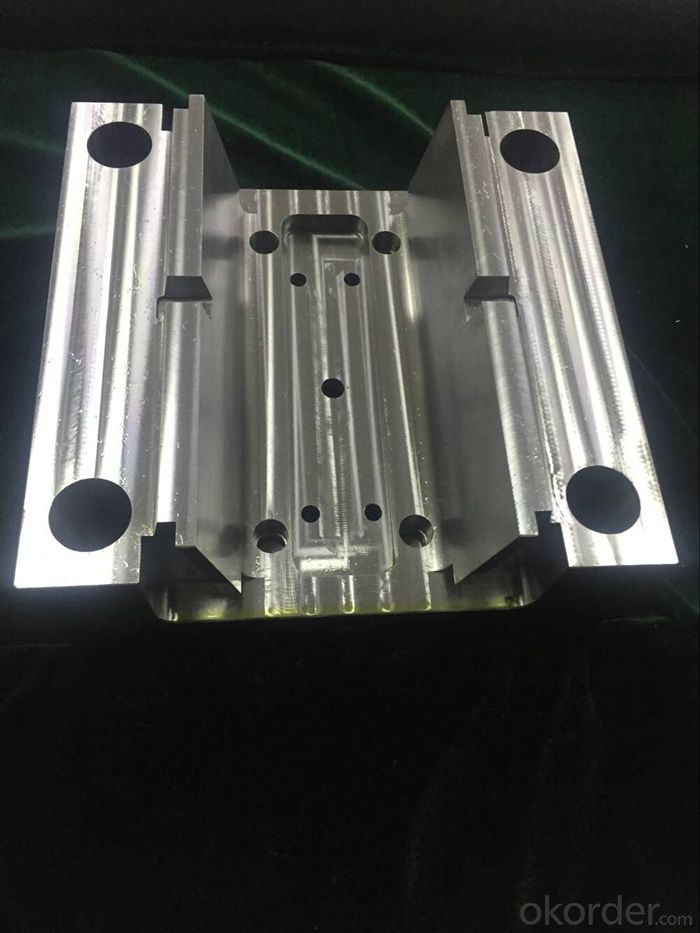

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:How expensive are the molds, or how expensive are they? Which quality is better?

- Nature is a lot more expensive, the quality is heel a few relations not big! However, when purchasing molds, choose one or more and you will have to look at the overall cost of making and making moulds. For example, oneself buy raw materials, the injection molding processing outside processing, processing fee calculate by minutes: hypothesis 1 minute processing fee for 1 yuan, hypothesis 2: a one and a second processing cycle is the same, 1 minutes out of the mold (may actually, because of the mold structure resulted in a more than a one of a long processing cycle: another possibility is the mold after big may need to use a larger tonnage injection molding machine to processing, processing cost will also increase because the corresponding consumption and increased), hypothesis 3: a mold price for 8000, a 12000, Then a second and a compared when adding a product can save the cost of 0.5 yuan, the mould cost differences between 12000-8000 = 4000 yuan can choose let two cavity modes in the total cost of processing, 8000 products achieve the same level, when need to processing the product quantity is greater than 8000, choose a second mould more cost-effective, less than 8000, choose one out of a mold more cost-effective! A long similar algorithms, but if the huge difference between cavity number will likely need to use different tonnage injection molding machine, the processing cost is sure to increase per unit time, it can't be in accordance with the simple proportion relationship to calculate!

- Q:What does the die EDM mean

- EDM, an acronym for the English acronym, is often used in professional fields. If the whole name is Electrical Discharge, it means electric spark Machining That's called electroprocessing. It is mainly used for a variety of complex shape and small precision workpieces, such as the punch die, die, intensive, fixed plate, stripper plate, such as forming tool, template, use of electric spark machine-shaping metal electrodes, all kinds of micro hole trough, narrow gap, curve and so on, with a small machining allowance, high machining accuracy, short production cycle, low manufacturing cost advantages, has obtained widespread application in the production, the wire-cut edm machine at home and abroad has more than 60% of the total number of electric machine.

- Q:How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

- Q:The effect of mould preheating and several methods of preheating

- Mould temperature machine (oil) heating: the heating is even, the temperature adjustment adopts intelligent control, the temperature control accuracy is high, can meet the strict requirement of high craft standard. The operation control and safety monitoring device is fully complete, the heating process is fully automatic, the operation is simple, and the installation is convenient. Closed circuit heating, low heat loss, significant energy saving effect, no environmental pollution, wide range. The drawback is that heating is transmitted by heat, which is slower

- Q:What is the role of the guide in the mould

- The "guide column" in the mould is also called "guide column".I hope my answer will help you

- Q:What is the difference between mould injection and blow molding?

- The process of injection molding and blow molding is different. Injection molding is the injection + pressure; The blow molding must have the head of the pipe, and the injection molding must have a gate section

- Q:Introduction to mould design and manufacturing

- Having the necessary natural science, social science and management scientific knowledge; Knowledge of computer knowledge, necessary network knowledge, common software knowledge; Basic knowledge of mechanical knowledge; The basic knowledge of mechanical design theory, mould material and forming process, mould design and manufacturing expertise of this major. Knowledge of mould CAD/CAM. Basic knowledge of mould maintenance is necessary. Have certain self-study ability; Have the tooling design, process implementation, technical management capability; Have the ability of machining and programming of mould control; With injection mould, stamping mould design and manufacturing capacity; It has the ability of the working ability of the fitter, the mould repair ability; Good computer base application and computer aided design manufacturing and management capability; Ability to design and process mould design with CAD/CAM software. Good verbal, verbal and interpersonal skills.

- Q:How does the concave and convex mold in the mold differentiate

- Upstairs said is right, for your own sake don't tube concave and convex, easy to use dynamic model set mode to distinguish, according to the dynamic set of injection molding machine templates, fixed on the dynamic template is called dynamic model, set the template name is fixed on the mold

- Q:Is there any way to keep the ice from sticking to the mold and remove it from the mold

- The best way is normal with mold, ice, frozen after good, put the mold in bowl with cold water for a while is ok, it is not necessary to use warm water, don't have to put the water into ice. And then you take it, and then you have a twist on both ends of the mold.

- Q:Make the mold with the dough

- Theoretically possible, but be aware of the following points: When taking the true model out, try to avoid the distortion of the internal cavity of the dough. The deformation of the cavity directly affects the later production accuracy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords