Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

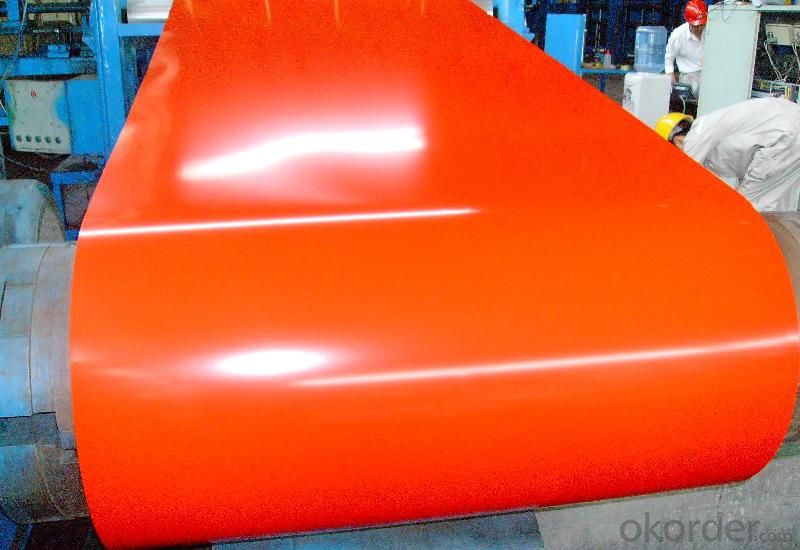

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

It generally displays workability, durability and weather resistance.

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Workability, durability

• Excellent heat resistance performance

• Excellent corrosion resistance • Excellent weather resistance • Capability of decoration, molding, corrosion resistance • High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:Any details about JinSong Ferritic Stainless Steel?

- JinSong SUS420J2 stainless-metallic/ X30Cr13 has larger intensity, hardness and hardenability than 12Cr13 metallic and 20Cr13 metallic after quenching. It has much less corrosion resistance to dilute nitric acid and vulnerable organic and organic acid than 12Cr13 metallic and 20Cr13 metallic in room temperature. you will get extra strategies on its good website**

- Q:Im getting a new guitar soon, and it has steel strings. ive heard that nilon strings are better? thanks:)

- Nylon is allegedly better for beginners because they don't cut into the fingers as much. Steel sounds much better, though.

- Q:I should have known, but magnets don't stick to stainless steel, so now I'm at a loss, I can't display my photos on the fridge. any ideas?

- Hi There, I am re-doing my kitchen and since my all stainless steel refrigerator will no longer be used to hold all my memos and pictures, I will hang a magnetic board in one area of my kitchen which will hold all the photos and memos that I had before and it would look very neat this way.. bably much neater than when they were on the fridge. Also, you can get a multiphoto frame for the photos and hang this on the wall. Then, the magnetic board can be just for notes and clips with invitations, etc. Hope this helps.

- Q:How are steel coils used in the production of metal fixtures?

- Steel coils are an essential component in the production of metal fixtures. These coils, which are typically made from carbon steel, are used as the primary raw material to manufacture a wide range of metal fixtures. The steel coils are first uncoiled and then cut into sheets of the desired size and thickness. These sheets serve as the base material for different types of metal fixtures, including brackets, hinges, handles, and other structural components. Once the sheets are cut, they undergo various forming processes such as bending, stamping, or rolling. These processes help shape the steel sheets into the specific design required for the metal fixture. For instance, bending may be used to create brackets or angles, while stamping can be used to form intricate patterns or shapes. After the forming processes, the steel sheets are often subjected to welding or joining techniques to assemble multiple components of the metal fixture. Welding ensures that the various parts are securely attached, providing strength and durability to the final product. Furthermore, steel coils also play a crucial role in enhancing the appearance and longevity of metal fixtures. They can be coated or treated with protective layers, such as galvanized or powder coatings, to prevent corrosion and provide a polished finish. These coatings ensure that the metal fixtures can withstand environmental factors and extend their lifespan. In summary, steel coils are an integral part of the production process for metal fixtures. They are transformed into sheets, which are then shaped, joined, and coated to create a wide range of functional and aesthetically pleasing metal fixtures used in various industries.

- Q:What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and scale, as well as shape defects like buckling, waviness, and edge cracks. Additionally, internal defects such as voids, inclusions, and segregation may also be present in steel coils.

- Q:What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide protection against corrosion, enhance durability, and improve the aesthetic appearance of the steel. Coatings create a barrier between the steel surface and the environment, preventing moisture, chemicals, and other corrosive elements from reaching the metal. Additionally, coatings can offer additional benefits such as heat resistance, UV protection, and improved paint adhesion, making the steel coils suitable for a wide range of applications in various industries.

- Q:I know this is an alloy, but can it be mixed to form a superior steel? Therefore less likely to stain?

- Unfortunately the stainless property does not make a 100% superior blade, unless you are not too concerned with how it performs. Generally speaking the mineral that allows steel not to stain is chromium so the higher content of chromium the more shiny and less likely to stain. The best performing blades however are the ones resistant to fatigue that usually contain high silica levels like japanese blades. Chromium on the other hand does make a less flexible and lower quality blade that also needs to be thicker, so it comes down to what will you be using it for.

- Q:How are steel coils inspected for chemical composition?

- Steel coils are inspected for chemical composition through a process called spectroscopic analysis. This involves taking a small sample from the coil and subjecting it to various tests, such as X-ray fluorescence or optical emission spectroscopy, to determine the precise elemental composition of the steel. This ensures that the steel meets the required specifications and quality standards.

- Q:What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they serve as the raw material for various components and parts. The coils are often used to fabricate structural frames, gears, shafts, and other essential elements that provide strength, durability, and stability to the machinery. The versatility and strength of steel make it an ideal material for withstanding the rigorous demands of industrial applications, ensuring the reliability and performance of the machinery.

- Q:How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the main component for heat exchange. These coils are responsible for transferring heat between the refrigerant and the air, allowing for effective cooling or heating in HVAC units.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords