PPR Male Threaded Socket with High Quality and Safety Guarantee for Water Supply

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

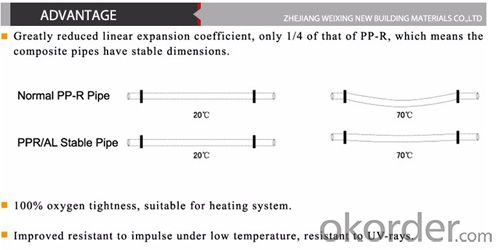

Advantages of PPR pipe

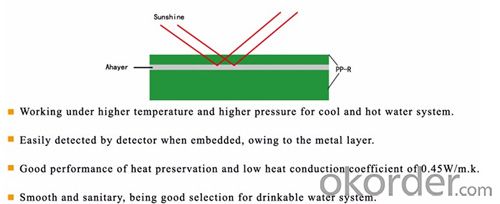

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Features of PPR

PPR pipe also known as three polypropylene pipe using a random copolymer polypropylene by extrusion become pipe, injection molded into the tube. PPR pipe is the development and application of new plastic pipe products in the early 1990s of the European. The late 1980s, PPR is the use of a gas phase copolymerization process so that about 5% PE in the molecular chain of PP random homogeneous polymerization (random copolymer) and a new generation of pipe materials. It has a good impact resistance and long-term creep performance.

PPR pipes have the features of light weight, corrosion resistance, no scaling, long life, but also have the following characteristics:

1. Non-toxic health: raw material molecule only carbon and hydrogen elements, not only for hot and cold water pipes, can be used to clean drinking water systems;

2. Energy-saving insulation: pipe thermal conductivity 0.21W / MK, steel is only 1/200;

3. Better heat resistance: PPR pipe Vicat softening point of 131.5 ℃, the maximum working temperature up to 95 ℃, can meet the water supply and drainage requirements specification hot water system;

4. Long life: PPR operating temperature 70 ℃, working pressure (PN) conditions under 1.0Mpa life of up to 50 years at room temperature (20 ℃) the service life of up to 100 years;

5. Install reliable connection: PPR pipe has good weld ability, pipe fittings can be used hot-melt and fused connections, easy installation, reliable joints, the strength of joints is greater than the strength of the pipe itself;

6. Recyclable materials: does not affect product quality.

How to choose a safe and economical PPR pipe?

1. Note that the overall pipeline utilization factor C (that is, the safety factor) is determined. General case, and long-term continuous use temperature is less than 70 ℃, optional C is equal to 1.25. On important occasions and long-term continuous use temperature of greater than or equal to 70 ℃, and is likely to run at a higher temperature for a long time, an optional C = 1.5;

2. For cold water (≤40 ℃) system, the choice of PN1.0 ~ 1.6Mpa pipe, fittings, hot water system for the selection of greater than or equal to 2.0Mpa pipe, tube.

- Q:I'm so scared ):What should I be doinglooking out for?worst case scenario?HELP

- The plastic tubes could have gotten lodged in his intestines somewhere. Best thing you can do is take him to a vet.

- Q:My husband and I hadm made steak and eggs for breakfast this morning with our left over steak from Christmas day. It was a large piece of filette mignon (sorry for the spelling if thats wrong) when he cut into his it he pulled.out a long clear plastic/rubber tube!! Clearly not part of the animal at all... it looks like.an air tube or something. About 2 inches long. . Its freaking me out! What should we do about this?? Infeel like we can't even trust if the meat we buy is all natural anymore.

- It's probably a tube used to inject the meat with some sort of aging solution or perservative. NO the food we get these days in not hardly natural. It's a shame what our people has let happen in this country, all for the almighty $. You get what you pay for, if you want good natural meat and other food it will cost a little more money. And Americans still think Lincoln abolished slavery. LOL. This country needed more slaves. All Lincoln did was take the color out of slavery and give them the right to choose who they slave for. We are still slaves, 7.50 an hour is slave wages. Why? Who can afford good quality food on a budget of 7.50 an hour?

- Q:How can I make a frosting tube?You know, the stuff you put frosting in squeeze it out?I want it to come out thin kind of so I can write Welcome homeCan't you like put it in a regular plastic baggy?But how do I make a nozel for it to come out of?...I need one within the next half hour. I Cannot go to the store fir anything..HELP

- you can put the frosting in a plastic baggie. sqeeze it all into one corner of the bag and snip the very tip of the corner off with scissors. the hole will act like a writing tip . Happy Decorating!

- Q:Are plastic tubes suitable for electrical wiring protection?

- No, plastic tubes are not suitable for electrical wiring protection.

- Q:How are plastic tubes filled with liquids or semi-liquids?

- Plastic tubes are typically filled with liquids or semi-liquids through a process called liquid filling. This process involves using specialized equipment, such as filling machines or pumps, to carefully fill the tubes with the desired substance. The liquid or semi-liquid is usually poured or pumped into the tubes, ensuring proper measurements and avoiding any spills or air bubbles. Once filled, the tubes are sealed to prevent any leakage or contamination.

- Q:What is the maximum temperature plastic tubes can be exposed to without deforming?

- The maximum temperature at which plastic tubes can be exposed without deforming varies depending on the type of plastic used. Generally, most plastic tubes can withstand temperatures ranging from 100 to 150 degrees Celsius without deforming. However, it is crucial to consult the specific material's datasheet or manufacturer's guidelines for accurate information on its maximum temperature resistance.

- Q:Can plastic tubes be used for gardening or irrigation purposes?

- Yes, plastic tubes can be used for gardening or irrigation purposes. They are commonly used as drip irrigation systems, allowing for efficient and targeted watering of plants. Plastic tubes are durable, flexible, and can be easily installed, making them a popular choice for gardeners and farmers alike.

- Q:I added a bit too much Oil into the engine, so I decide that I would be able to suck the oil out with some tubing. However part of the plastic tubing fell off into the dipstick hole and it possibly in the oil pan now. I call some mechanic, and ended up having some say that it will damage the engine and some saying that it will not effect the engine. Can someone give me a more in-depth explanation. On how I can remove the plastic tubing? and How is will effect the engine? Should I even drive it?

- If the tubeing was long enough, you might be able to fish it out with a very long bent wire with a small enough hook to go inside the tube you droped in the dip stick hole.

- Q:Can plastic tubes be used for architectural installations?

- Yes, plastic tubes can be used for architectural installations. They are often used for temporary structures, such as exhibition displays or event installations. Plastic tubes offer flexibility in design, are lightweight, and can be easily shaped and manipulated to create unique architectural features. Additionally, they can be transparent or colored, allowing for creative lighting effects. However, it is important to consider the specific requirements of the installation and the durability of the plastic material to ensure it meets safety standards and can withstand environmental conditions.

- Q:i tried puttin super glue to the end of a coat hanger but it didnt work. what are some other ways i can fish it out. it is about 3 or 4 inches deep

- 1. Try using a piece of rubber tubing that is just large enough to fit over the dipstick but small enough to go into the dipstick tube and that is long enough to do the job without getting lost inside the tube, about a foot or two long piece should do. It should only cost a few bucks at the auto parts store for them to cut a piece of tubing for you. You also may need a long flat-tip screwdriver to position the dipstick away from the dipstick tube wall and towards the center of the dipstick tube. Gently push the tubing over the dipstick end and then slowly pull it out of the dipstick tube. 2. If this doesn't work then the dipstick tube *should* be removable, sometimes nut or bolts will hold it secure in place and those items as well as any parts in the way of access of the dipstick tube will need to be removed. Good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Male Threaded Socket with High Quality and Safety Guarantee for Water Supply

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords