Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Short Fiber Needle Punched Nonwoven Geotextile

1. Product Description:

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles.

Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

Geotextiles can be used as:

* Filtration or separation layers in civil engineering projects of roads and railway construction;

* Protect layer for geomembranes in landfill construction;

* Coastal defence applications

* Landscaping projects to maintain soil and protect land surfaces and structures from weeds and root growth.

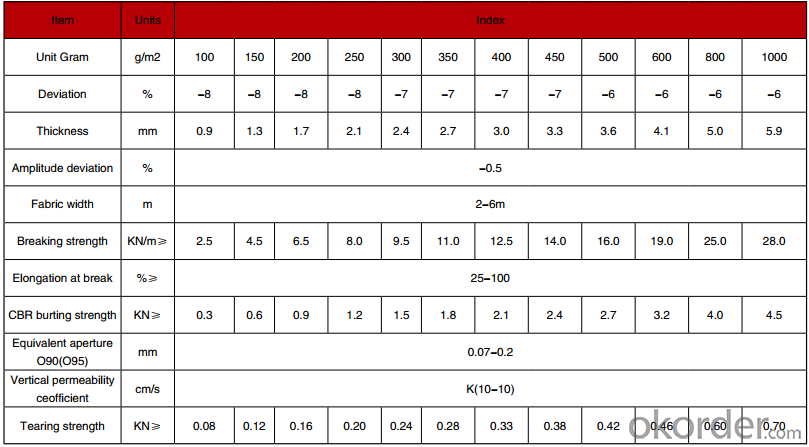

2. Data sheet:

3. Main Features

2) High temperature resistance to up to 230℃ maintaining structure stability and original physical properties;

3) High flat drainage and vertical permeability;

4) High creep resistance;

5) Resistance of erosion of chemicals in soil as well as the corrosion of gasoline and diesel etc;

6) High elongation under certain stress, thus able to adapt to uneven and irregular bases;

4. Packaging & Shipping:

white fabric bag or black PE bag outside or as required.

7 days after received deposite

5. Applications of NON-Woven Geotextile :

Non woven Geotextiles can be widely used in railways, highways, sports halls, ,garbage dump ,dams, hydraulic construction, tunnels, coastal beaches, land reclamation, environmental protection and other projects.

Notes : The specification is based on mass area ratio.

When the actual specification is between adjacent specifications in this table, it is necessary to calculate the corresponding evaluation indicators in accordance with the interpolation method;

If the range in table is exceeded, it is necessary to determine the evaluation indicators through consultation by the supply and demand sides.

6.Pictures

7. FAQ:

Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000,but it is negotiable.

Q3:What is your payment terms?

A: T/T,Western Union,L/C.

Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:What are the types of geotextiles used in railway subgrade

- Railway is more demanding than the highway, the railway subgrade is to bear and pass the orbital gravity and the dynamic structure of the train structure, is the basis of the track is to ensure that the train running an important building, the roadbed is a rock and soil structure, in a variety of topography, Geological and climatic conditions, such as floods, debris flow, earthquakes and so on. Therefore, geotextile in which the main play of his reinforcement and isolation, reinforcing the main material to enhance the shear and tensile deformation of the ability to prevent reflection of cracks in the road; isolation is the separation of different materials to maintain their own performance. As the geotextile itself is not waterproof, in the old road renovation over the asphalt mixture will form impermeable complex, in addition to preventing cracks and a certain degree of water defense, the railway subgrade is usually used in the two cloth a film complex Published, so with 600 grams of filament geomembrane more

- Q:How do geotextiles help in soil stabilization?

- Geotextiles aid in soil stabilization by acting as a barrier, preventing the erosion of soil particles, improving soil structure, and providing reinforcement to the ground. They distribute loads evenly, reduce water flow velocity, and enhance soil filtration, thereby enhancing the stability and strength of the soil.

- Q:What are the benefits of using geotextiles?

- Geotextiles offer numerous benefits such as erosion control, soil stabilization, and drainage improvement. They help prevent soil erosion by acting as a barrier and holding soil particles in place. Geotextiles also stabilize the soil by distributing load forces, thus enhancing the strength and durability of structures. Additionally, they promote efficient drainage, allowing water to pass through while retaining soil particles. Overall, geotextiles provide cost-effective solutions for various civil engineering and environmental applications.

- Q:What does geotextile mean?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. First, the characteristics: 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain full strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience, as the material light, soft, so the delivery, laying, construction convenience. 6, complete specifications: width of up to 9 meters. Is currently the widest product, the unit area quality: 100-1000g / ㎡. Second, the role: 1, isolation 2, filtration 3, drainage 4, reinforced 5, protection 6, anti-puncture

- Q:How are geotextiles used in landfills?

- Geotextiles are used in landfills to help enhance the stability, drainage, and filtration of the waste disposal site. They are typically placed between the layers of soil and the landfill liner system to prevent soil erosion, control gas and liquid migration, and provide reinforcement for the overall structure.

- Q:How to apply the geotextile of the retaining wall filter

- Our manufacturer, a professional construction team

- Q:Shield Machine Tool material which is the hardest

- If I remember correctly, it should be chromium carbide material

- Q:15 km highway how much geotextile

- Depends on how wide your road, come to the square, you know about how much. Manufacturers produce geotextiles

- Q:What are the specifications for geotextiles in roadways?

- Geotextiles used in roadways typically have specific specifications, including high tensile strength, puncture resistance, and durability to withstand heavy traffic loads. They are often made from synthetic materials like polypropylene or polyester, with a minimum weight per unit area to ensure sufficient strength and stability. Additionally, geotextiles for roadways should have proper drainage capabilities to prevent water buildup and promote better road performance.

- Q:What are the durability considerations for geotextiles?

- Durability considerations for geotextiles include factors such as tensile strength, resistance to ultraviolet (UV) degradation, chemical resistance, and abrasion resistance. Geotextiles should have sufficient tensile strength to withstand the stresses and strains imposed on them during installation and the lifespan of the project. UV degradation can weaken geotextiles over time, so it is important to choose products with appropriate UV resistance. Chemical resistance ensures that geotextiles remain intact and functional in the presence of chemicals or contaminants in the soil or water. Additionally, geotextiles should be resistant to abrasion to withstand any potential friction or rubbing against other materials or objects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords