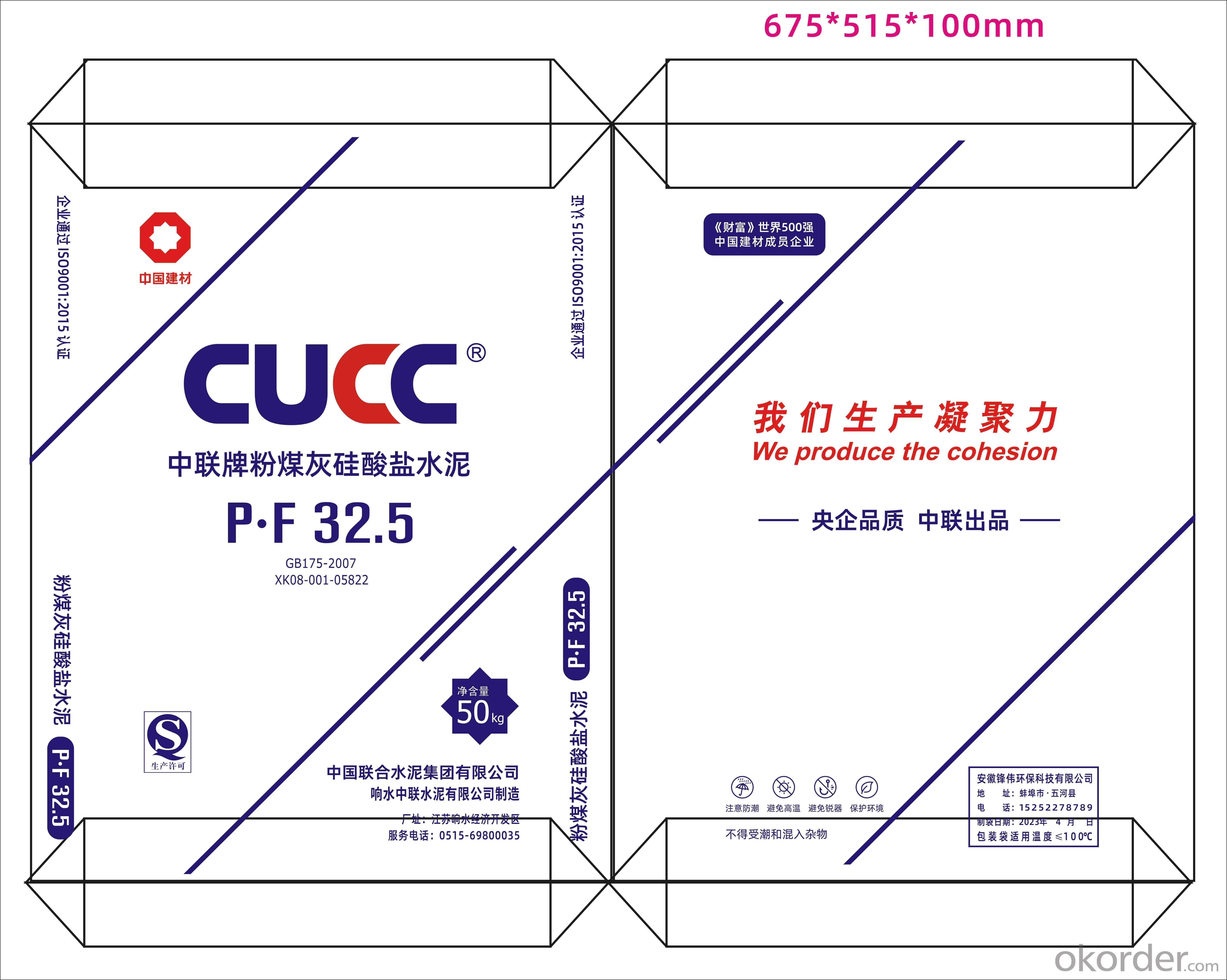

Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Supplier:

CHINA UNITED CEMENT XIANGSHUI CO.,LTD

CHINA UNITED CEMENT XIANGSHUI CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Produce Description

▶ Exported Products:

1. Portland cement in accordance with GB standard: PSA 32.5, PO 42.5, PO 52.5..

▶ Input raw materials for production including:

→ Limestone exploited from raw materials source of the plant.

→ Clay exploited and transported from raw materials source of the plant.

→ Adjustment additive: Iron ore purchased and transported to the plant by truck.

→ Cement additives: basalt, gypsum …

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

Payment Term: Contact us.

- Q:Some say it is, some say it isn't. I'm wanting to create a vaulted tunnel below grade and I need it to be able to resist the standard tendency for cement fines to wash away in wet conditions.

- Most construction cements today are hydraulic, and most of these are based on Portland cement, which is made primarily from limestone, certain clay minerals, and gypsum in a high temperature process that drives off carbon dioxide and chemically combines the primary ingredients into new compounds. Non-hydraulic cements include such materials as (non-hydraulic) lime and gypsum plasters, which must be kept dry in order to gain strength, and oxychloride cements, which have liquid components. Lime mortars, for example, set only by drying out, and gain strength only very slowly by absorption of carbon dioxide from the atmosphere to re-form calcium carbonate through carbonatation.

- Q:What is a chemical that softens rock and cement?

- Hydrochloric acid softens cement. You can buy large containers of it for removing cement from brickwork. It will also attack some types of rock, especially limestones. Be careful with it though!

- Q:I was going to tile a bedroom and was wondering if I could use glue on cement board, if so is there anything special that I would have to do, or any certain type of glue to get?

- No. You don't use glue to put tile on cement board. You need tile mastic. Go to Home Depot or Lowes and get it in the tile section.

- Q:Building materials distribution business projects can increase the cement products and steel it?

- Building materials distribution business projects can increase the cement products and steel cement: water mixing into a plastic slurry, can cement sand, stone and other materials both in the air hardening and hardening in the water of the powder-like hydraulic cementitious material

- Q:hey im zack and im reseachin portland cement u think u guys help me i want to find out what is it and how its used? THANKS 4 UR HELP AND TIME

- It's the most common form of cement and made from concrete, mortar, stucco and grout. It was developed in England and the result was thought of as being comparable with Portland limestone, an oft used building stone obtained from the south coast in Dorset. Thar's what it's named after.

- Q:So......I'm a little over my head here. Started taking down wallpaper and wouldn't you know it, there was layer, upon layer and then I accidentially started taking up the backing and came to cement. Have done what I could to salvage what I did, but have decided I'm going to use textured wallpaper over the existing. Do you think it'd be alright to paper right over and on the cement?

- concrete or cement is a porous surface and will not let the glue stick for the long haul. you need to paint the surface with a sealer before you began. a good sealer to use is dryloc. you can pick it up in any paint store or hardware store.

- Q:Like peanuts look like building materials, very light and mixed with the use of cement.

- You say is the ceramsite,Ceramics ah obviously do the insulation.

- Q:doing a red brick fireplace at home.what sand/cemnt ratio should i use?

- 5:1 sand/ cement is a good allrounder

- Q:Or, why does cement curl at all?

- I have never seen cement curl, possibly don't understand- sorry. As far as dryness. Concrete when poured starts to cure and set immediately. The outer edges cool or cure faster than the inside area because there is more sq inches exposed to the air. Sometime in the late evening go out barefoot and stand on a sidewalk that has been in the direct sunlight during the day. You will notice if you put your foot on the edge it is much cooler than the middle - same thing the edge has more surface and edge exposed to allow it to cool quicker. Sorry about the curling - I just didn't understand - my fault.

- Q:There was a fire and the beam burned at the end that rest on the cement block. I want it to be solid when the new beam goes on.

- You did not give much info on the cement block just the beam. How big of a block are we talking about? What is the construction of the cement block? 2,000 psi? 2500 psi? How intense was the fire? Most fires will not hurt cement blocks. How much weight is this beam holding? After you take the burnt beam off you can make a better assessment on the cement block. I'm willing to bet my last dollar, it will hold up a new beam fine. Good Luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Supplier:

CHINA UNITED CEMENT XIANGSHUI CO.,LTD

CHINA UNITED CEMENT XIANGSHUI CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords