Hig Efficient &Easy Installation Wholely Assembled Box Girder Template

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

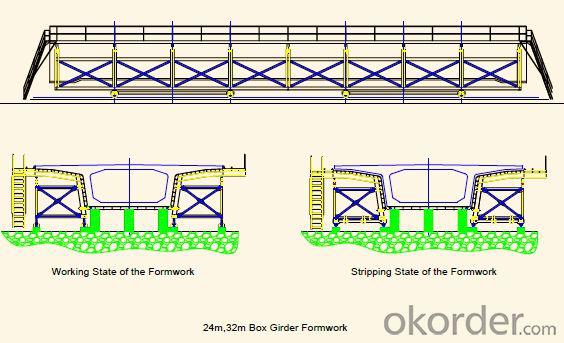

Wholely Assembled Box Girder

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q:How to calculate the length of the beam, beam template area

- Is the template area, there are two times in each cross beam, then the results of the calculation of the sub beam cross-sectional area (a few minus a few) is the

- Q:How to put the beam formwork in concrete structure

- When the carpenter die down from the ceiling! To determine! But you need to check it regularly! Not everyone does it by the rules!

- Q:The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- This option is not available in the design parametersCan only be used in the calculation of the calculation of the book or the program alone: double fastener!

- Q:The calculation formula of the beam column for the construction of the concrete and the use of the template area of the detailed point of the best thank you

- Refer to JGJ 162-2008 construction formwork safety technical specifications

- Q:10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- For the concrete structure engineering, the concrete strength can reach the design of the concrete cube compressive strength of the standard value of a certain amount, before the template can be removed the standard value.

- Q:How to do irrigation formwork

- For your understanding of the 200*350, this is the inside of the beam height. The true beam is 200*500. without the need to deduct plate thickness

- Q:What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

- Q:First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- The template of the beam can be completed in two or once. The two is complete, first beam bottom mould, then binding steel beam and plate, and side template; a beam bottom and side is template template and template to support end, then lashing steel beam on the template, binding after the beam falls on the beam within the template, and then tie plate reinforced.

- Q:I would like to ask the three sides of the template is calculated on the surface of which is the three? Novice do not understand thank you

- Generally, there are two kinds of formwork support:Area of contact surface between concrete and formwork

- Q:When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hig Efficient &Easy Installation Wholely Assembled Box Girder Template

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords