column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

china quick form concrete column formwork

Application

column formwork for concrete forming of square columns

Installation

as easy as film faced plywood, but no need release agent

Dismantling

Handle carefully without violent damage and scratch to ensure more usage in good condition

Cleaning

Just clean by water

Maintenance & Storage

No oil treatment, place the panel flat, away from direct sunlight and water.

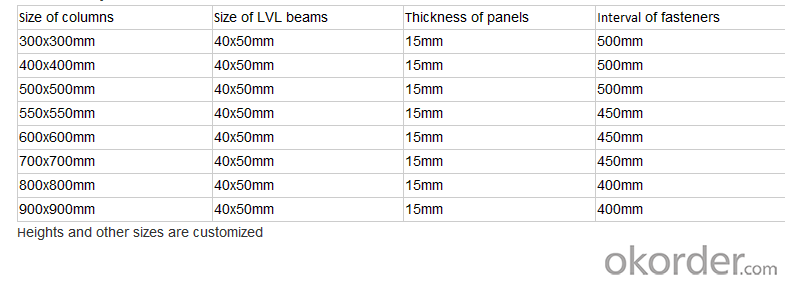

Product options

Advantages

1. reusable 50 times at least

2. quick installation & seamless joining to prevent the leakage of concrete

3. painted accessories, high resistance to rust

4. quick dismantling without concrete release agent

5. nice concrete finish without reworkP

Packing

- Q:How does steel frame formwork prevent concrete shrinkage and cracking?

- Steel frame formwork prevents concrete shrinkage and cracking by providing strong support and reinforcement to the concrete structure. The steel frame acts as a rigid and stable framework, ensuring that the concrete remains in its intended shape during curing. This prevents excessive shrinkage and cracking that may occur due to internal stresses or inadequate support. Additionally, the steel frame formwork allows for proper alignment and placement of reinforcement bars, further increasing the strength and durability of the concrete structure.

- Q:Can steel frame formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel frame formwork can be used for both cast-in-place and precast concrete construction. Steel frame formwork provides a versatile and durable solution that can be easily adjusted and reused for different construction projects. It ensures precise and accurate shaping of concrete elements, whether they are cast on-site or produced in a precast facility.

- Q:Can steel frame formwork be used in projects with strict quality control requirements?

- Yes, steel frame formwork can be used in projects with strict quality control requirements. Steel frame formwork is known for its durability, strength, and stability, making it suitable for demanding construction projects. It offers precise and accurate concrete forming, ensuring high-quality results. Steel frame formwork is also resistant to warping or bending, which helps maintain the integrity of the structure. Additionally, steel frame formwork allows for easy assembly, disassembly, and reusability, making it a cost-effective option for projects with strict quality control requirements. Overall, steel frame formwork is a reliable choice that can meet the high standards and specifications needed in projects with rigorous quality control measures.

- Q:How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through a combination of factors. Firstly, the steel frame itself is designed with sturdy anchor points and connection mechanisms that help secure it firmly to the ground. Additionally, the formwork is often supported by vertical supports such as props or scaffolding, which further enhance its stability and prevent any movement. This ensures that the formwork remains in place during the concrete pouring and curing process, ultimately resulting in a properly anchored structure.

- Q:Are there any restrictions on the formwork height that can be achieved with steel frame formwork?

- There are no specific restrictions on the formwork height that can be achieved with steel frame formwork. Steel frame formwork is known for its strength and durability, allowing it to support higher heights compared to other types of formwork systems. However, the maximum achievable formwork height may depend on various factors such as the design of the steel frame system, the type of support structure used, and the load-bearing capacity of the surrounding structure. It is important to consult with structural engineers and formwork manufacturers to determine the appropriate formwork height based on the specific project requirements and safety standards.

- Q:What are the different types of concrete testing and quality control methods used with steel frame formwork?

- There are several different types of concrete testing and quality control methods used with steel frame formwork. These methods are utilized to ensure the strength, durability, and overall quality of the concrete used in construction projects. One common testing method is the slump test, which measures the consistency and workability of the fresh concrete. This involves filling a cone-shaped mold with the concrete, compacting it, and then removing the mold to observe the slump or settlement of the concrete. This test helps to determine if the concrete has the appropriate water-cement ratio and if it can be easily placed and compacted in the formwork. Another important method is the compressive strength test, which measures the ability of the concrete to withstand compression or pressure. This test involves casting concrete cylinders or cubes and subjecting them to a gradual increase in pressure until they fail. The results of this test help to determine if the concrete has reached the required strength for the specific application. Furthermore, concrete mix design is an essential aspect of quality control. It involves determining the proportions of various materials, such as cement, aggregates, water, and admixtures, to achieve the desired properties of the concrete. This process considers factors such as strength requirements, durability, workability, and environmental conditions. In addition to these tests, other quality control methods include visual inspection of the formwork to ensure it is properly aligned and secured, as well as checking for any leakage or defects that may affect the concrete pour. Non-destructive testing methods, such as ultrasonic testing, can also be used to assess the integrity and quality of the concrete without damaging the structure. Overall, the combination of these concrete testing and quality control methods helps to ensure that the concrete used with steel frame formwork meets the required standards and specifications. This ensures the structural integrity and longevity of the construction project, providing a safe and reliable end result.

- Q:Are there any environmental benefits to using steel frame formwork?

- Yes, there are several environmental benefits to using steel frame formwork in construction projects. Firstly, steel is a highly durable material that can be used repeatedly without losing its structural integrity. This means that steel formwork can be used for multiple construction projects, reducing the need for new formwork materials and minimizing waste generation. Additionally, steel frame formwork can be easily dismantled and reassembled, making it more versatile and adaptable for different construction needs. Furthermore, steel is a recyclable material, meaning that at the end of its life cycle, it can be recycled and used to produce new steel products. This reduces the demand for new steel production and the associated environmental impacts, such as mining and energy consumption. Moreover, steel frame formwork can contribute to energy efficiency in construction. Due to its superior strength and load-bearing capacity, steel formwork allows for the construction of more slender and lightweight structures. This leads to a reduction in the overall material used in construction, resulting in energy savings during the manufacturing, transportation, and installation processes. In conclusion, the use of steel frame formwork offers several environmental benefits, including durability, reusability, recyclability, and energy efficiency. By choosing steel frame formwork, construction projects can minimize waste generation, conserve resources, and reduce their environmental footprint.

- Q:How does steel frame formwork contribute to the speed of construction?

- There are several ways in which steel frame formwork contributes to the speed of construction. To begin with, its durability and strength are well-known. This allows for faster construction as it can withstand higher concrete pressures and can be reused multiple times. The steel frames provide stability and support, making the pouring of concrete efficient and safe. Moreover, steel frame formwork is highly adaptable and can be easily adjusted and modified to meet different project requirements. This flexibility enables faster assembly and disassembly, reducing the overall construction time. Additionally, steel frame formwork is lightweight compared to traditional formwork materials like timber. This facilitates transportation and handling, resulting in quicker installation and dismantling on site. Furthermore, steel frame formwork is compatible with modern construction techniques such as precast and modular construction. These techniques allow for faster construction by prefabricating various elements off-site and quickly assembling them using the steel frame formwork system. In conclusion, the utilization of steel frame formwork significantly expedites the construction process by providing durability, adaptability, a lightweight design, and compatibility with modern construction techniques.

- Q:Can steel frame formwork be used for bridge construction?

- Yes, steel frame formwork can be used for bridge construction. Steel frame formwork is a versatile and durable solution that is commonly used in various construction projects, including bridges. It provides strength and stability to the structure, allowing for efficient and precise concrete placement. Additionally, steel frame formwork can be easily adjusted and reused, making it a cost-effective option for bridge construction.

- Q:What is the role of steel frame formwork in achieving a smooth concrete finish?

- Achieving a smooth concrete finish relies heavily on the crucial role of steel frame formwork. This type of formwork acts as a temporary mold or structure that securely holds the concrete in place as it cures and hardens. It plays a vital role in providing support and stability to the wet concrete, preventing any unwanted deformations or cracks during the curing process. One of the main advantages of utilizing steel frame formwork lies in its ability to deliver precise and accurate shapes to the concrete. The rigid and robust design of the steel frames ensures that the concrete maintains its desired dimensions and form. This becomes particularly significant when constructing structures with intricate details or complex designs. Moreover, steel frame formwork actively contributes to achieving a smooth concrete finish by minimizing any imperfections on the surface. The inflexible structure of the steel frames effectively prevents any movement or shifting of the concrete, resulting in a consistent and even surface. This becomes especially important when the concrete surface needs to exhibit visual appeal or when a smooth finish is required for functional purposes, such as flooring or walls. Furthermore, steel frame formwork offers the benefit of easy removal and reuse. After the concrete has fully cured and hardened, the formwork can be dismantled and removed, leaving behind a clean and finished concrete surface. The steel frames can then be cleaned and utilized again for future projects, reducing construction costs and minimizing waste. In conclusion, the indispensability of steel frame formwork in achieving a smooth concrete finish cannot be overstated. It provides the necessary support and stability to ensure the concrete maintains its desired shape and dimensions, while simultaneously minimizing surface imperfections. By employing steel frame formwork, construction projects can achieve high-quality concrete finishes that are both visually appealing and functionally effective.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords