Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Custom SF63 Rectangle / Square

Column / Wall Construction

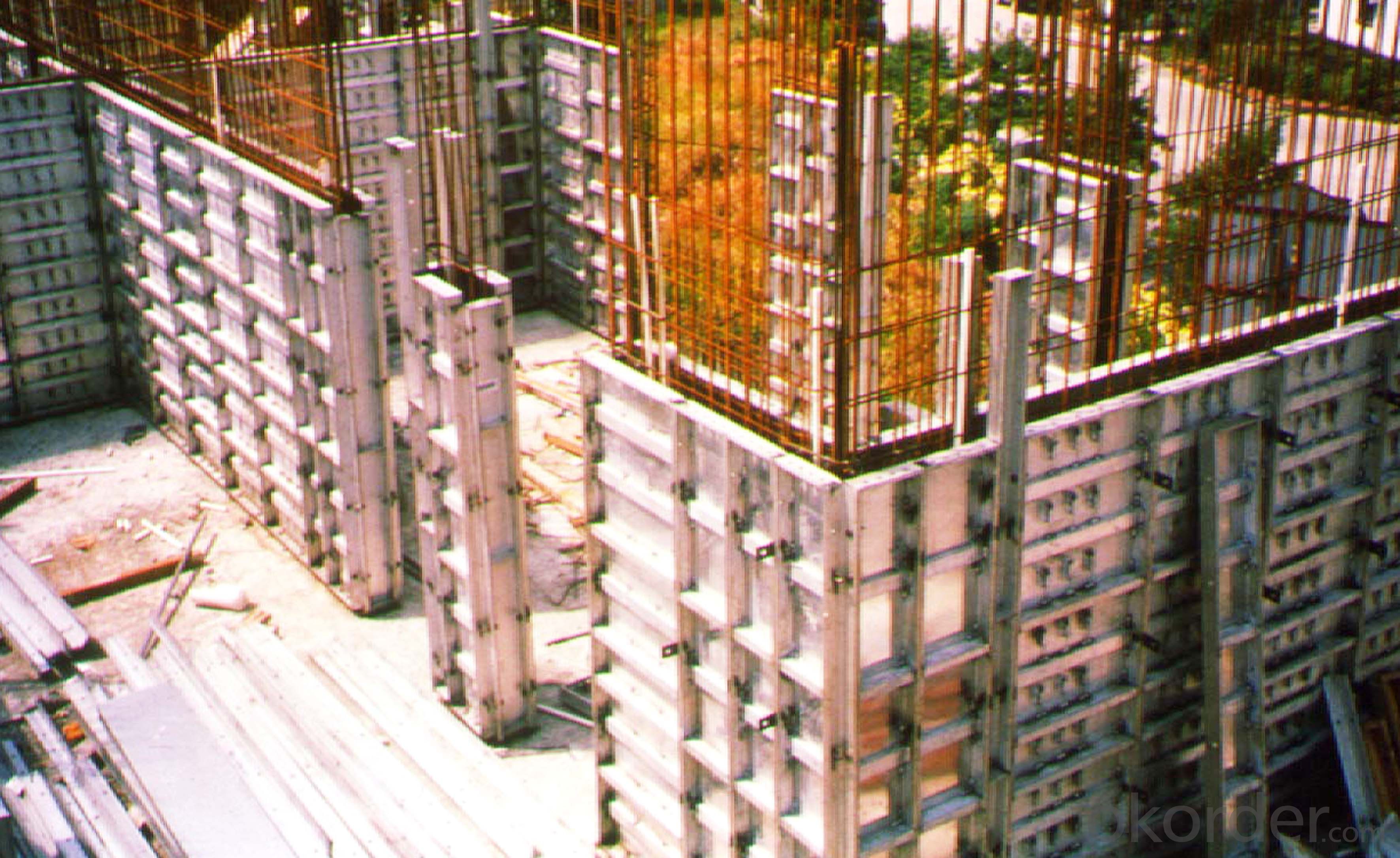

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q:What are the different types of steel used in steel frame formwork?

- There are several types of steel commonly used in steel frame formwork, including mild steel, high-strength low-alloy (HSLA) steel, and stainless steel. Mild steel is the most common type and is known for its affordability and versatility. HSLA steel offers higher strength and durability while maintaining a relatively low weight. Stainless steel is chosen for its corrosion resistance and is typically used in environments where exposure to moisture or chemicals is a concern.

- Q:How does steel frame formwork prevent concrete segregation or bleeding during pouring?

- Steel frame formwork helps prevent concrete segregation or bleeding during pouring in several ways: 1. Stability: The steel frame provides stability and prevents excessive movement of the formwork during pouring. This reduces the chances of concrete segregation, where the heavier aggregates separate from the cement paste, causing an uneven distribution of materials. 2. Reinforcement: Steel frame formwork often includes additional reinforcement elements, such as steel bars or mesh, which help hold the concrete together and prevent segregation. These reinforcements also enhance the overall strength and durability of the concrete structure. 3. Tight fit: Steel formwork is typically designed to fit tightly against the edges of the concrete structure, leaving no gaps or openings. This tight fit restricts the movement of the concrete, minimizing the potential for segregation or bleeding. 4. Vibration resistance: Steel frame formwork is generally more rigid and resistant to vibrations compared to other types of formwork materials. This rigidity helps reduce the likelihood of concrete segregation, as vibrations can cause the aggregates to separate from the cement paste. 5. Smooth surface: Steel formwork often has a smooth surface, which allows for better flow and distribution of the concrete during pouring. The absence of rough or uneven surfaces minimizes the risk of segregation, as the concrete can easily flow and settle evenly within the formwork. Overall, steel frame formwork provides a stable, reinforced, tight-fitting, vibration-resistant, and smooth surface to prevent concrete segregation or bleeding during pouring. These features help ensure a uniform distribution of materials and enhance the strength and quality of the final concrete structure.

- Q:How does steel frame formwork handle concrete pouring at different heights?

- Steel frame formwork is a versatile and reliable system that can easily handle concrete pouring at different heights. The key to its effectiveness lies in its adjustable nature and strong structural design. Firstly, steel frame formwork is designed to be adjustable, allowing it to be easily adapted to different heights. The frames can be extended or shortened to the desired level, ensuring that the formwork fits securely and firmly against the concrete structure. This adjustability feature is particularly useful when pouring concrete at different heights, as it allows for seamless transitions and ensures a consistent and uniform finish. Additionally, the steel frame formwork system is built with durability and strength in mind. Steel is a robust material that can withstand the weight and pressure of the concrete during pouring. It provides excellent support and stability, ensuring that the formwork remains in place and does not deform or collapse under the weight of the concrete. This is crucial when pouring concrete at different heights as it guarantees the safety and integrity of the structure. Moreover, steel frame formwork is versatile and can be easily customized to accommodate various architectural designs and requirements. It can be used for both horizontal and vertical concrete placements, making it suitable for different types of construction projects. Whether pouring concrete at ground level or at elevated heights, the steel frame formwork system can be adapted to meet the specific needs of each situation. In conclusion, steel frame formwork is a reliable and adaptable system that handles concrete pouring at different heights with ease. Its adjustable nature and strong structural design ensure that it provides secure support and stability during the pouring process. This versatility and durability make steel frame formwork an ideal choice for construction projects requiring concrete placement at varying heights.

- Q:How does steel frame formwork contribute to the overall sustainability of the construction industry?

- Steel frame formwork contributes to the overall sustainability of the construction industry in several ways. Firstly, steel is a highly durable material that can withstand the rigors of construction and can be reused multiple times. This means that steel frame formwork can be used for multiple projects, reducing the need for new formwork materials and minimizing waste. Additionally, steel frame formwork allows for efficient construction processes. The use of steel frames provides a strong and stable support system for concrete during the pouring and curing stages, resulting in high-quality structures. The precision and accuracy of steel formwork also ensure that less material is wasted, reducing the overall environmental impact of construction projects. Furthermore, steel is a recyclable material, meaning that at the end of its lifespan, it can be melted down and used to create new steel products. This promotes a circular economy and reduces the demand for virgin materials, ultimately saving energy and reducing greenhouse gas emissions associated with the production of new materials. Lastly, steel frame formwork can contribute to the sustainability of the construction industry by reducing the overall construction time. The use of prefabricated steel formwork systems allows for faster and more efficient construction processes, minimizing disruption to the environment and local communities. In conclusion, steel frame formwork contributes to the overall sustainability of the construction industry through its durability, reusability, recyclability, and efficiency. By reducing waste, conserving resources, and promoting a circular economy, steel formwork helps to minimize the environmental impact of construction projects and supports the long-term sustainability of the industry.

- Q:What are the safety certifications required for steel frame formwork?

- The safety certifications required for steel frame formwork typically include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and OHSAS 18001 or ISO 45001 for occupational health and safety management systems. Additionally, certifications such as CE marking, UL listing, or AS/NZS standards compliance may also be necessary depending on the specific country or region.

- Q:How does steel frame formwork handle concrete curing in different weather conditions?

- Steel frame formwork is a versatile and durable system used for concrete construction. It is designed to handle concrete curing in various weather conditions. In hot weather, steel frame formwork helps to prevent excessive evaporation of moisture from the concrete surface. The steel frames provide a rigid structure that holds the concrete in place, preventing it from cracking due to rapid drying. Additionally, the steel formwork can be easily insulated, which helps in maintaining the required temperature for proper concrete curing even in extreme heat. In cold weather, steel frame formwork helps to protect the concrete from freezing. The steel frames act as a barrier, shielding the concrete from low temperatures and preventing it from freezing during the curing process. Furthermore, insulating materials can be added to the steel formwork to enhance its thermal efficiency, ensuring that the concrete cures properly even in freezing temperatures. In rainy or humid weather conditions, steel frame formwork is built with watertight seals to prevent water from entering the concrete structure. This is crucial as excess moisture can weaken the concrete and affect its strength. The steel formwork, along with the use of waterproof membranes and sealants, helps to create a protective barrier against water infiltration, allowing the concrete to cure effectively. Overall, steel frame formwork is specifically designed to handle different weather conditions during concrete curing. Its robust construction and ability to withstand extreme temperatures and moisture ensure that the concrete cures properly, resulting in a strong and durable structure.

- Q:How does steel frame formwork handle the placement of modular and prefabricated elements within the concrete structure?

- When it comes to placing modular and prefabricated elements in a concrete structure, steel frame formwork is an excellent option. This particular formwork system is specifically designed to provide a solid and stable support structure for various construction components. One of the main benefits of steel frame formwork lies in its versatility. It can easily be adjusted to accommodate different sizes and shapes of modular and prefabricated elements. The modular design of the system allows for effortless customization, ensuring a precise fit for each element. In addition, steel frame formwork offers a high level of strength and durability, ensuring the concrete's structural integrity. This is particularly important when dealing with heavy or large modular elements, as the steel frame can withstand the demands of the construction process. Furthermore, steel frame formwork provides accurate placement of modular and prefabricated elements. The system is designed for easy alignment and adjustment, allowing for precise positioning of each component. This guarantees that the elements seamlessly integrate into the concrete structure, resulting in a robust and flawless final product. What's more, steel frame formwork enables efficient and speedy construction. Its lightweight nature allows for quick assembly and disassembly, reducing construction time and increasing productivity. This is especially advantageous when working with modular and prefabricated elements, as their installation can be done more efficiently. In conclusion, steel frame formwork is an ideal choice for placing modular and prefabricated elements in a concrete structure. Its versatility, strength, accuracy, and efficiency make it a reliable and effective solution for construction projects.

- Q:Are there any specific requirements for bracing steel frame formwork?

- Yes, there are specific requirements for bracing steel frame formwork. These requirements are in place to ensure the stability and safety of the structure during the construction process. Firstly, it is important to have a comprehensive understanding of the design and structural requirements of the steel frame formwork system. This includes the load-bearing capacity, the maximum height and width of the formwork, and the specific bracing details provided by the manufacturer or structural engineer. The bracing system should be designed to resist the lateral loads and forces that may act on the formwork during concrete pouring and curing. This includes wind loads, pressure from the wet concrete, and any other potential forces that may be present on the construction site. The bracing should be securely anchored to the ground or to other structural elements to provide stability and prevent any movement or collapse of the formwork. The anchoring method should be appropriate for the specific site conditions and take into account factors such as soil type, foundation strength, and potential lateral forces. It is also important to regularly inspect and maintain the bracing system to ensure its effectiveness throughout the construction process. This may include checking for any signs of damage, corrosion, or weakening of the bracing components, and promptly addressing any issues that may arise. In summary, the specific requirements for bracing steel frame formwork include thorough understanding of the design and structural requirements, designing the bracing to resist lateral loads, securely anchoring the bracing system, and regularly inspecting and maintaining the bracing components. Meeting these requirements will help ensure the stability and safety of the steel frame formwork during construction.

- Q:Can steel frame formwork be used for both monolithic and modular slab construction?

- Both monolithic and modular slab construction can utilize steel frame formwork. This versatile and resilient system easily adjusts to different construction methods and requirements. In monolithic slab construction, steel frame formwork provides a stable and robust support structure for pouring concrete. The steel frames assemble and adjust effortlessly to achieve the desired shape and dimensions of the slab. With its ability to withstand concrete pressure and weight, the formwork guarantees a smooth and even finish. Similarly, steel frame formwork proves effective in modular slab construction. This approach involves manufacturing individual slab sections off-site and subsequently assembling them at the construction site. The steel frame formwork ensures precise and accurate assembly of the modular slabs, ensuring high-quality and consistent results. The strength and stability of the steel frames allow for safe transportation and installation of the modular slabs. In summary, steel frame formwork is a versatile solution suitable for both monolithic and modular slab construction. Its strength, durability, and adaptability make it an excellent choice for various construction projects.

- Q:How does steel frame formwork compare to plywood formwork?

- Two commonly used methods of construction formwork are steel frame formwork and plywood formwork, each having their own advantages and disadvantages. Durability is a major point of distinction between steel frame formwork and plywood formwork. Steel frame formwork is highly durable and can be reused multiple times, making it a cost-effective choice in the long run. Conversely, plywood formwork has a shorter lifespan and may require frequent replacements, resulting in higher costs. In terms of strength, steel frame formwork surpasses plywood formwork in load-bearing capacity. This makes it suitable for heavy-duty construction projects that require support for high loads. Plywood formwork, though not as strong, can still be effective for lighter construction projects. Another difference lies in the ease of assembly and disassembly. The modular design of steel frame formwork typically makes it easier to assemble and dismantle, leading to faster construction progress and increased efficiency. Plywood formwork, while generally straightforward to use, may require more time and effort for assembly and disassembly. Both steel frame formwork and plywood formwork offer advantages in terms of flexibility and versatility. Steel frame formwork can be easily adjusted to different shapes and sizes, making it suitable for complex construction designs. Plywood formwork, although less flexible, can still be adapted to various construction projects with appropriate modifications. When it comes to cost, steel frame formwork is generally more expensive upfront due to higher material and manufacturing costs. However, its long-term durability and reusability can offset these initial expenses. On the other hand, plywood formwork is initially more affordable but may require more frequent replacements, resulting in higher overall costs over time. Ultimately, the choice between steel frame formwork and plywood formwork depends on the specific requirements of the construction project. Factors such as load-bearing capacity, durability, flexibility, and cost must be carefully considered to determine the most suitable formwork method for a particular construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords