Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

pouring straight wall

Concrete Wall Formwork

Waterproof Wall Formwork

retaining wall formwork

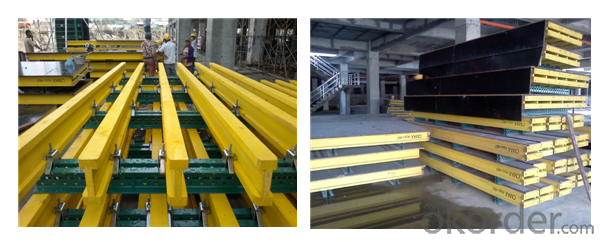

Custom High Security H20 Timber Beam Formwork for Straight Concrete Wall

Description:

1. Structure sketch

TBW system-A is a kind of formwork for pouring straight wall, it is composed of several pieces of Tim-formwork, yoke, tie rod, wing nut, etc.

It will be designed according to wall’s size.

Competitive Advantage:

1. Prefabricated connection, convenient and efficient.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 60KN/m2 with weight of 55-60kg/m2.

If required, the formwork can be specially designed for higher concrete pressures.

3. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

Applications:

- Q:How is the quality of the concrete surface achieved with steel frame formwork?

- The use of steel frame formwork results in a high-quality concrete surface for several reasons. Firstly, the rigid and stable structure of steel frame formwork ensures that the fresh concrete is evenly poured and compacted, preventing any irregularities or deformations. Additionally, the design of steel frame formwork includes adjustable elements like clamps, tie rods, and spacers, which allow for precise alignment and leveling. This guarantees that the concrete is poured at the correct thickness and with consistent dimensions, resulting in a smooth and uniform surface. Furthermore, steel frame formwork often incorporates form liners or surface treatments that can create decorative patterns or textures on the concrete. These liners or treatments can be easily attached to the steel frames, enabling the creation of aesthetically pleasing finishes. Moreover, the durability and reusability of steel frame formwork are advantageous, especially in large construction projects. The ability to reuse the same formwork multiple times without compromising the quality of the concrete surface ensures uniformity throughout the project. In conclusion, the use of steel frame formwork ensures a high-quality concrete surface due to its stability, adjustability, and durability. These factors contribute to the creation of a smooth, even, and aesthetically pleasing surface that meets all required standards and specifications.

- Q:Are there any limitations to the size or shape of concrete structures that can be formed using steel frame formwork?

- Yes, there are limitations to the size and shape of concrete structures that can be formed using steel frame formwork. One limitation is the maximum height of the structure that can be achieved. Steel frame formwork systems have height restrictions due to the stability and strength of the steel frames. If the structure's height exceeds the maximum limit, additional support systems such as scaffolding or shoring may be required to ensure the stability of the formwork. Another limitation is the complexity of the shape that can be achieved. Steel frame formwork is generally designed to create straight, rectangular or square structures. While some curved or irregular shapes can be achieved, it may require additional modifications or customizations to the formwork system, which can increase the complexity and cost of the construction process. Moreover, the size and weight of the formwork panels can pose limitations. Steel frame formwork panels are typically heavy and can become cumbersome to handle as their size increases. This can make it challenging to maneuver and assemble the formwork panels for larger and more complex structures. Additionally, the availability of skilled labor and equipment can also impact the size and shape limitations of concrete structures formed using steel frame formwork. If the construction project lacks experienced workers or appropriate equipment, it may be difficult to handle and assemble the formwork for larger or more intricate structures. In summary, while steel frame formwork offers flexibility in creating concrete structures, there are limitations in terms of height, shape complexity, panel size, and availability of skilled labor and equipment. It is essential to consider these limitations during the design and planning stages of a construction project to ensure the successful implementation of steel frame formwork.

- Q:What is the typical lead time for manufacturing steel frame formwork?

- Manufacturing steel frame formwork usually takes varying lead times due to factors like design complexity, required quantity, raw material availability, and manufacturer's production capacity. On average, the lead time can span from a few weeks to a few months. It is crucial to note that the lead time encompasses design approval, fabrication, quality control, and transportation. Hence, it is recommended to consult the manufacturer or supplier to obtain a precise estimate tailored to your specific needs and circumstances.

- Q:How does steel frame formwork compare to other types of formwork in terms of speed of construction?

- Steel frame formwork is generally considered to be faster in terms of construction compared to other types of formwork. This is because steel frames are pre-fabricated and can be easily assembled and disassembled, allowing for quicker and more efficient construction processes. Additionally, steel frame formwork provides a high level of strength and stability, enabling faster pouring and curing of concrete. Overall, the use of steel frame formwork can significantly expedite the construction timeline compared to other formwork systems.

- Q:PKPM how to add lateral restraint steel frame

- As for the landlord said lateral constraints, generally refers to the vertical component, that is to increase the size of the vertical component size. Or express clearly in question.If you help, please accept, thank you!

- Q:How does steel frame formwork contribute to sustainable construction practices?

- Steel frame formwork contributes to sustainable construction practices in several ways. Firstly, steel is a highly durable and long-lasting material, which means that the formwork can be reused multiple times, reducing the need for new materials and minimizing waste. This reusability also leads to cost savings and a more efficient construction process. Additionally, steel frame formwork is highly adaptable and can be easily modified to suit different project requirements, reducing the need for new formwork designs and materials. This flexibility improves construction efficiency and reduces the overall environmental impact. Furthermore, steel is a recyclable material, and at the end of its life cycle, the formwork can be recycled and used in other construction projects, reducing the demand for new steel production and conserving natural resources. Overall, steel frame formwork promotes sustainable construction practices by reducing waste, improving efficiency, and supporting the principles of circular economy through its reusability and recyclability.

- Q:How does steel frame formwork prevent concrete segregation or bleeding?

- Steel frame formwork prevents concrete segregation or bleeding by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. When concrete is poured into the steel frame formwork, it is contained within the framework, preventing the mixture from spreading or separating. The steel frame acts as a barrier, ensuring that the concrete remains in place and does not segregate or bleed. The steel frame formwork also helps in maintaining the correct consistency and workability of the concrete. It provides a smooth and even surface against which the concrete can be compacted, reducing the chances of air pockets or voids. This compacting action helps to prevent bleeding, which occurs when water rises to the top of the concrete surface and causes the cement and aggregate to separate. Additionally, the steel frame formwork provides support and stability to the concrete structure as it cures. This prevents any movement or displacement of the concrete, which can lead to segregation or bleeding. The rigid nature of the steel frame ensures that the concrete maintains its desired shape and form, resulting in a strong and durable final product. In conclusion, steel frame formwork is an effective solution for preventing concrete segregation or bleeding. Its rigid and stable structure contains the concrete, maintains its consistency, and provides support during the curing process, resulting in a high-quality and homogeneous finished concrete structure.

- Q:How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q:Can steel frame formwork be used for healthcare and medical facilities construction?

- Yes, steel frame formwork can be used for healthcare and medical facilities construction. Steel frame formwork is known for its strength, durability, and versatility, making it suitable for various construction projects including healthcare and medical facilities. It provides a stable and secure framework that can support the weight of heavy concrete structures, ensuring the safety and stability of the building. Additionally, steel frame formwork can be easily assembled, disassembled, and adjusted, allowing for flexibility in design and efficient construction processes. Moreover, steel is a non-combustible material, which is important for healthcare and medical facilities that require high fire safety standards. Overall, steel frame formwork is a reliable and efficient choice for constructing healthcare and medical facilities.

- Q:Are there any specific considerations for using steel frame formwork in earthquake-prone areas?

- There are specific factors to take into account when using steel frame formwork in earthquake-prone areas. To begin with, it is crucial to ensure that the steel frame formwork is designed and constructed in accordance with the seismic design requirements of the specific area. This entails considering variables such as the anticipated seismic activity level, soil conditions, and prevailing building codes and regulations. The steel frame formwork should possess sufficient strength and rigidity to withstand the seismic forces that may be exerted during an earthquake. This may necessitate the use of thicker steel sections, reinforcement, or additional bracing to enhance the structural integrity and stability of the formwork system. In earthquake-prone areas, establishing a secure connection between the steel frame formwork and the supporting structure is also of utmost importance. This can be achieved through appropriate anchorage and tie-down systems that are designed to resist the lateral forces generated by an earthquake. Proper attention should be given to the detailing and installation of these connections to ensure their effectiveness. Furthermore, it is advisable to utilize high-quality steel and ensure the proper maintenance and inspection of the steel frame formwork. Steel with high tensile strength and good ductility can offer better resistance to the dynamic forces experienced during an earthquake. Regular inspection and maintenance can aid in identifying any potential issues or damage, thereby enabling timely repairs or replacements to preserve the formwork's integrity. Lastly, the safety of workers during the construction process in earthquake-prone areas must be taken into consideration. This may involve implementing additional safety measures, such as providing adequate training on earthquake response and evacuation procedures, ensuring the availability of safe zones during seismic events, and utilizing protective equipment to minimize the risk of injuries. Overall, the use of steel frame formwork in earthquake-prone areas necessitates careful attention to design, construction, connection, material quality, maintenance, and worker safety. It is essential to consult experienced engineers and adhere to local building codes and regulations to ensure the safety and stability of construction in such areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches