Anti-Skid Needle Punched Non Woven Geotextile with High Strength CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

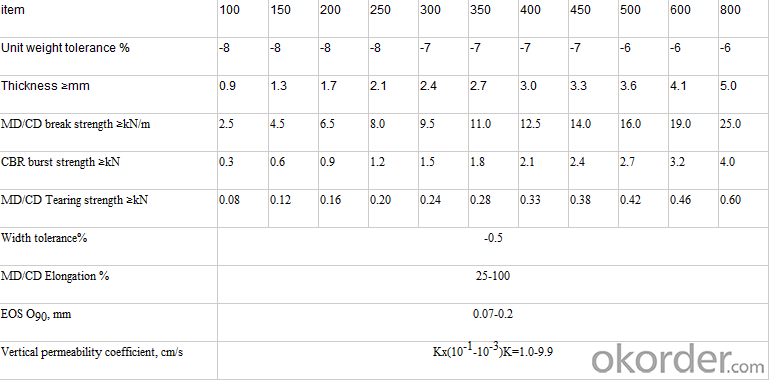

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

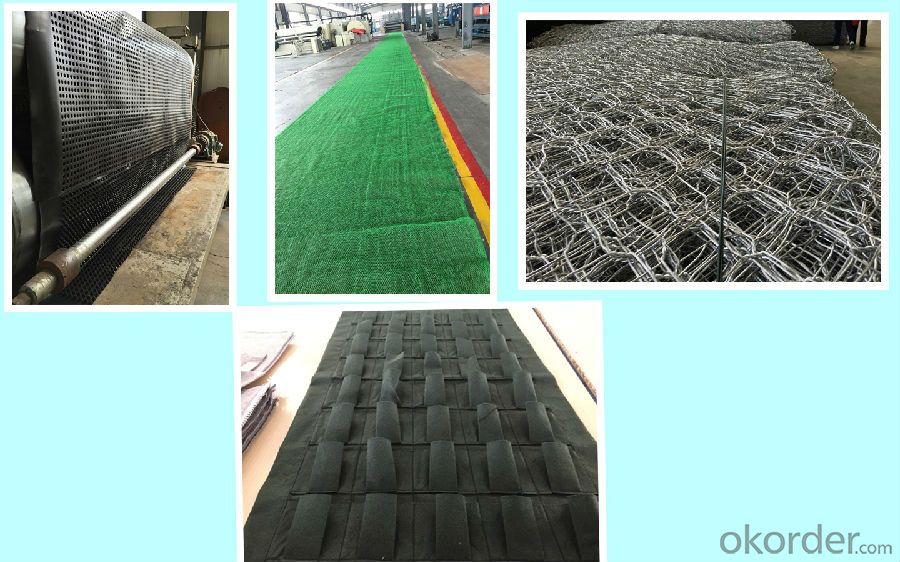

A: Yes, please check the pictures:

- Q:How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, increases soil strength, and improves overall stability.

- Q:How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing erosion control, stabilization, and reinforcement. These synthetic fabrics are installed between the soil layers of the slope, acting as a barrier to prevent soil movement and erosion caused by water flow or wind. Geotextiles also enhance the overall stability of the slope by improving soil drainage, reducing pore water pressure, and increasing soil strength.

- Q:Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

- Q:How are geotextiles different from other types of geosynthetics?

- Geotextiles are a type of geosynthetic material that is primarily used for filtration, separation, and reinforcement purposes in various civil engineering applications. Unlike other types of geosynthetics such as geogrids or geomembranes, geotextiles are typically made from woven or non-woven fabrics, which provide them with unique characteristics like high permeability, flexibility, and resistance to biological degradation. These properties enable geotextiles to effectively filter water, prevent soil erosion, and improve soil stability, distinguishing them from other geosynthetics that may have different functions or structural compositions.

- Q:Can geotextiles be used in shoreline protection projects?

- Yes, geotextiles can be used in shoreline protection projects. Geotextiles are often used to stabilize and reinforce soil in coastal areas. They can help prevent erosion, improve drainage, and provide a barrier against waves and tides.

- Q:How are geotextiles tested for durability?

- Geotextiles are tested for durability through various methods including tensile strength testing, abrasion resistance testing, and exposure to environmental conditions such as UV radiation, temperature variations, and chemical exposure. Additionally, geotextiles may undergo puncture resistance testing and hydraulic conductivity testing to assess their long-term performance and suitability for specific applications.

- Q:Are geotextiles resistant to fire?

- Yes, geotextiles can be made resistant to fire through the use of specific materials and treatments.

- Q:Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are permeable fabrics that can act as a filter and reinforcement, helping to stabilize the sand and prevent erosion. They can be used as a protective layer between the beach sediment and the underlying soil, preventing sand washout and promoting beach stability. Geotextiles are commonly employed in beach nourishment projects to enhance coastal resilience and mitigate erosion.

- Q:What are the design considerations for geotextile-reinforced pavement systems?

- Some of the key design considerations for geotextile-reinforced pavement systems include selecting the appropriate type and quality of geotextile, determining the required reinforcement strength, considering the expected traffic loads and patterns, evaluating the subgrade conditions, ensuring proper installation and compaction of the geotextile, and assessing long-term durability and maintenance requirements. Additionally, factors such as drainage, stability, and environmental impact should also be taken into account during the design process.

- Q:Do you need to cover the geotextile?

- Do not need, bathroom waterproof can choose a professional kitchen and toilet waterproof paste, or K11 waterproof slurry, water and electricity transformation, as long as the direct brushing on the base surface can be done until the waterproof layer can do 48 to 72 hours Of the closed water experiment, no problems can be posted after the brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-Skid Needle Punched Non Woven Geotextile with High Strength CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords