Al-Zinc Coated steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

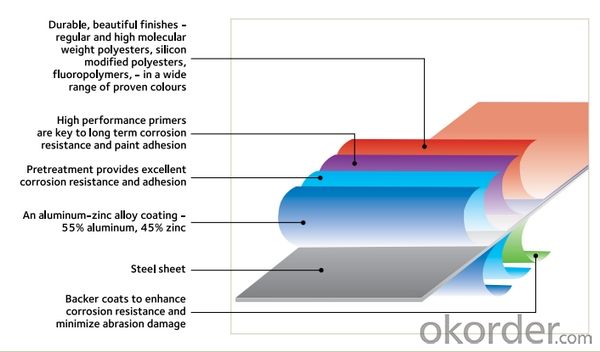

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How are steel coils processed for pickling or oiling?

- Steel coils are processed for pickling or oiling through a series of steps. First, the coils are uncoiled and flattened to ensure a consistent surface. Next, they are cleaned to remove any dirt or debris using a chemical solution or mechanical cleaning method. After cleaning, the coils are immersed in a pickling bath, which typically consists of an acid solution. This bath removes any scale or oxides from the surface of the steel. Once pickling is complete, the coils are rinsed and dried to remove any remaining pickling solution. Finally, if oiling is required, a thin layer of oil is applied to the surface of the coils to prevent corrosion and improve their overall appearance.

- Q:How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q:How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they are shaped and cut to create various components such as frames, brackets, and structural supports. These coils provide the necessary strength and durability required for heavy-duty equipment used in farming operations.

- Q:What are the limitations of using steel coils in certain applications?

- One limitation of using steel coils in certain applications is their susceptibility to corrosion. Steel coils can rust when exposed to moisture or harsh environments, which can affect their structural integrity and performance. Additionally, steel coils can be heavy and bulky, making them less suitable for applications that require lightweight materials or intricate designs. Finally, steel coils may not be suitable for applications that require specific electrical or thermal conductivity properties, as steel is not the most conductive material in these aspects.

- Q:What are the common transportation defects in steel coils?

- Common transportation defects in steel coils may include edge damage, surface scratches, deformation, and coil slippage. These defects can occur due to mishandling during loading, unloading, or transit, leading to potential quality issues and compromised structural integrity of the steel coils.

- Q:How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q:How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Sheet stainless steel is about $2.00 to $2.75 per lb. in the US right now for a 2B stainless steel without any special finish. The cost of a sink or counter is going to vary widely. The labor to fabricate it is going to be a lot higher than the material cost so the price per pound is not going to tell you much. In California a custom 6' counter would be somewhere between $1,200 and $3,000. A standard size single compartment sink would be about half of that.

- Q:What are the different coil handling equipment options available for steel coils?

- There are several different coil handling equipment options available for steel coils, depending on the specific needs and requirements of the industry. 1. Coil Cars: Coil cars are used to transport steel coils from one location to another within a facility. They are typically equipped with hydraulic or mechanical lifting mechanisms to safely load and unload the coils onto other equipment or storage racks. 2. Coil Upenders: Coil upenders are used to rotate steel coils from a horizontal to a vertical position, or vice versa. This equipment is essential for loading and unloading coils onto coil cars or other machinery, as well as for storage purposes. Upenders can be operated manually or hydraulically, depending on the weight and size of the coils. 3. Coil Lifters: Coil lifters are designed to safely handle steel coils during lifting and transportation. They are typically equipped with adjustable arms or hooks that securely grip the coil's inner diameter. Coil lifters can be operated using hydraulic, mechanical, or electromagnetic mechanisms, depending on the weight and size of the coils. 4. Coil Turnstiles: Coil turnstiles are used to efficiently store and retrieve steel coils. They are designed to hold multiple coils in a vertical position, allowing for easy access and retrieval. Turnstiles can be rotated manually or automatically, using hydraulic or mechanical systems. 5. Coil Reels: Coil reels are used to unwind steel coils and feed them into processing machinery, such as stamping presses or roll forming machines. They are equipped with adjustable tension controls to ensure a smooth and consistent feed. Coil reels can be operated manually or automatically, depending on the level of automation required. 6. Coil Cradles: Coil cradles are used to support steel coils during storage or transportation. They are designed to evenly distribute the weight of the coil, preventing deformation or damage. Coil cradles can be stationary or equipped with wheels for easy movement. Overall, the different coil handling equipment options available for steel coils provide a range of solutions for efficient and safe handling, storage, and processing of these heavy and valuable materials. The choice of equipment will depend on factors such as coil size, weight, production volume, and specific industry requirements.

- Q:i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- soft steel is used at times...(com block ammo is flush with steel cased products) Steel rusts so you have to paint it or coat it... the coatings leave residue in firearms that can cause a stoppage. Brass is the A choice for casings. No Rust, it has no issues for reactivity, wont spark, expands to seal chambers... and in many cases can be reloaded and used over again.

- Q:How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that minimizes the risk of damage. They are usually placed on pallets or in racks to keep them off the ground and provide stability. Additionally, they are often secured with bands or straps to prevent movement during storage and transportation. Proper ventilation is also important to prevent moisture buildup, which can cause corrosion. By implementing these measures, the risk of damage to steel coils is significantly reduced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Al-Zinc Coated steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords