Virony Tiles

Virony Tiles Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Pvc Tiles For Walls Fiberglass Sheets For Roofing Decorative Lights For Ceiling Ceiling Lights For Sitting Room Ceiling Brackets For Lights Hanging Ceiling Chairs For Bedrooms 42 White Ceiling Fan With LightHot Searches

Used Foam Board Insulation For Sale Plastic Roof Tiles For Sale Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Gypsum Board Price Per Sheet In India High Density Mdf Board Suppliers Calcium Silicate Pipe Insulation Price 5 8 Type X Gypsum Board Price Calcium Silicate Board Suppliers In Uae Gypsum Board Price Per Sheet Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Pre Laminated Board Price List Durock Cement Board Price Century Waterproof Plywood Price List Greenply Waterproof Plywood Price List Solar Inverter Mounting BoardVirony Tiles Supplier & Manufacturer from China

Okorder.com is a professional Virony Tiles supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Virony Tiles firm in China.Hot Products

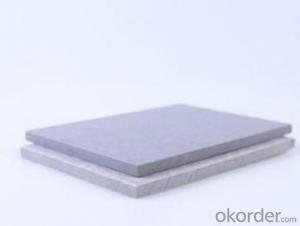

High Quality and Non-Asbestos Versatile Sandblasting Cutting Edge Calcium Silicate Board For Ceiling

FAQ

- Calcium and calcium silicate board and calcium carbonate plate distinction and contact

- Smallpox modeling Less use of calcium silicate board. hardness. Moisture, waterproof. Deformation. Better performance on fire. 2 price is not much.

- Is the calcium silicate board gypsum board?

- Calcium silicate board is mainly made of siliceous materials and calcareous materials through a variety of production processes, with good fire and water, light high strength, long life, heat and sound absorption, high density and other characteristics, is the future light The main direction of the development of the partition wall. Gypsum board mainly by the construction of gypsum as raw material, the surface of a special paper for the face, after processing from the plate, but also has a light high strength, heat and sound absorption, construction and other characteristics.

- Calcium silicate board with asbestos and non-asbestos how to choose

- Two are containing asbestos fibers, and non-asbestos fiber, of course, not asbestos fiber prices are more expensive, simply introduce what is asbestos asbestos, asbestos is a good natural silicate fiber products, with high insulation Tensile strength, corrosion resistance and electrical insulation, asbestos added calcium carbonate board impact resistance and insulation than not asbestos is much better, while adding asbestos calcium silicate board price is cheaper, but also in the noise There are also very good results, is generally used for partition board and ceiling decoration. How many projects procurement and home improvement personnel often can not tell how these two partition panels to choose, and many people are man-made asbestos Is a harmful material to the human body, but this is undeniable is indeed a certain harm to the human body, but the building materials manufacturers through the national inspection of asbestos are within the scope of the national security, if the Chengdu building materials market selection of this When the partition wall plate must make the building materials dealers to produce the country's quality inspection report

- Fiber reinforced calcium silicate board is to do with the cut off it?

- Calcium silicate board is non-polluting, environmentally friendly, new building materials, and aerated concrete and concrete hollow block, belong to the new wall materials, has replaced the traditional clay brick. Calcium silicate board in the high-rise building and frame light board building system, is an indispensable wall material for the construction of the wall of the factory complex; mechanized construction; put an end to the construction of wet operations;

- Gypsum board with calcium silicate board which is good? What are the advantages and disadvantages?

- Of course, calcium silicate board is good, calcium silicate board is gypsum board upgrade products.

- I need a tool that can cut calcium silicate board, Bo deep good, where can I buy Wuxi?

- We are Shijiazhuang company to buy their stuff of course good to buy, you can check online in your local dealer, their saw blade is good, our company has been with it

- Calcium silicate board how to deal with smooth surface, that is, I would like to foil in the calcium silicate board, is to be very common to paste the bottom,

- The first lower number of sand belt sand flat, and then a high head of the belt polishing, pits or wood fiber fluff easily blistering, you can try or ask the belt or sanding equipment manufacturers

- Calcium silicate board surface putty Why crack?

- First, the first clean seams at the end of the dust, after cleaning, in the seams sweep a white latex, can achieve better anti-cracking effect. (Figure 1) Second, with a scraper putty putty evenly embedded in the seam mouth. (Figure 2) Three, and then immediately wiped the self-adhesive fiber mesh belt, and the net completely affixed to the putty, and then a layer of putty on the net belt putty. (Figure 3) Fourth, in order to further strengthen the anti-cracking effect, to be a putty completely dry (about 5 hours, the case of wet weather will increase), with a putty in the thin layer (slightly wider than the seam chamfering area and slightly higher On the board) (Figure 4) Five, until the putty completely dry, with sandpaper on the surface of the caulking, sanding, so that the entire board smooth.