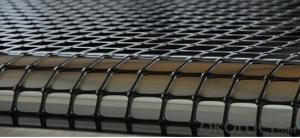

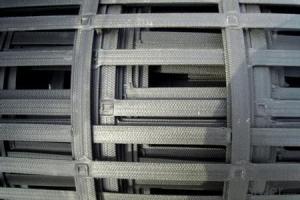

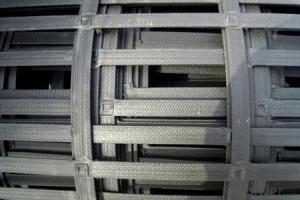

Unilock Geogrid

Unilock Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleUnilock Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Unilock Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Unilock Geogrid firm in China.Hot Products

FAQ

- Geogrids are used in civil engineering to reinforce and stabilize soil structures. They are typically made of high-strength polymer materials and are placed within the soil to provide additional strength and stability. Geogrids help distribute loads, prevent soil erosion, and improve the overall performance of infrastructure projects like roads, retaining walls, and embankments.

- Geogrids help in reducing soil compaction by providing reinforcement and stabilization to the soil. They distribute the applied load more evenly, preventing concentrated pressure points that can lead to compaction. This allows for better load-bearing capacity, improved soil structure, and increased permeability, ultimately reducing the likelihood of soil compaction.

- Some of the key design considerations for geogrid-reinforced pavements include selecting the appropriate geogrid material and properties based on the project requirements, determining the optimal placement and orientation of the geogrid within the pavement structure, considering the compatibility between the geogrid and other pavement materials, evaluating the long-term performance and durability of the geogrid, and ensuring proper construction techniques and quality control during installation. Additionally, factors such as traffic loading, subgrade conditions, climate, and drainage need to be taken into account for a successful design of geogrid-reinforced pavements.

- The standards for geogrid testing and certification are outlined by various organizations such as ASTM International (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards cover a range of parameters including tensile strength, elongation, aperture size, junction strength, and durability. Testing methods and acceptance criteria are defined to ensure that geogrids meet the necessary performance requirements for their intended applications. Certification is typically granted by accredited third-party laboratories or certification bodies after successful compliance with these standards.

- Yes, geogrids can be used in the reinforcement of soil-nailing systems. Geogrids are commonly used to enhance the stability and strength of soil structures, including soil nail walls. They provide additional tensile strength and distribute the loads more evenly, improving the overall performance and durability of the soil-nailing system.

- There are several different installation methods for geogrids, including direct burial, mechanical anchoring, and adhesive bonding. Direct burial involves placing the geogrid in the soil and covering it with additional soil to secure it in place. Mechanical anchoring involves using pins or stakes to anchor the geogrid to the soil or other structures. Adhesive bonding involves using a specialized adhesive to bond the geogrid to a surface, such as a retaining wall. The choice of installation method depends on the specific project requirements and conditions.

- Yes, geogrids can be used in the reinforcement of railway ballasts. Geogrids are commonly employed in railway construction and maintenance projects to enhance the stability and load-bearing capacity of the ballast layer. By distributing the load more evenly, geogrids help to prevent excessive settlement and deformation, improving the overall performance and longevity of the railway track.

- The recommended geogrid roll width for specific applications can vary depending on factors such as the type of soil, the slope angle, and the desired level of reinforcing strength. It is best to consult with a geotechnical engineer or supplier who can assess the specific project requirements and provide a suitable recommendation.