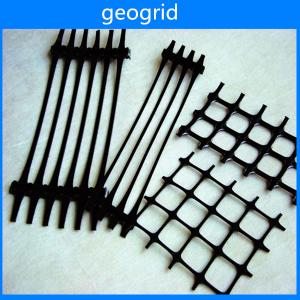

Tensar Tx-5 Geogrid

Tensar Tx-5 Geogrid Related Searches

Geogrid Machine Geogrid Plastic Paver Plastic Geogrid Black Poly Geogrid Geogrid Landscape Fabric Geogrid Fabric Driveway Geogrid Cost Per Square Foot Geogrid Grass Driveway Geogrid Grass Geogrid RollHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleTensar Tx-5 Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Tensar Tx-5 Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tensar Tx-5 Geogrid firm in China.Hot Products

FAQ

- Design considerations for geogrids in reinforced soil slopes prone to seismic activity include: 1. Geogrid selection: Choosing a geogrid with sufficient strength, stiffness, and durability to withstand the dynamic forces generated during seismic events is crucial. The geogrid should have high tensile strength and low elongation properties to effectively restrain the soil mass. 2. Connection details: Ensuring proper connection between the geogrid and the facing system is essential. The connection should be able to accommodate the movement and deformation of the soil during seismic events without compromising the stability of the reinforced slope. 3. Slope geometry: The slope geometry should be carefully designed to minimize the risk of failure. Factors such as slope angle, height, and overall stability need to be considered to prevent excessive stress on the geogrid and ensure it can effectively reinforce the soil. 4. Soil properties: Understanding the behavior of the soil under seismic loading is crucial for designing the geogrid reinforcement. The soil properties, such as shear strength, liquefaction potential, and settlement characteristics, should be evaluated to determine the appropriate geogrid type, spacing, and embedment depth. 5. Dynamic analysis: Conducting dynamic analysis to assess the potential response of the reinforced slope to seismic forces is important. This analysis helps in determining the required strength and stiffness of the geogrid and ensures that the slope remains stable during seismic events. 6. Construction quality control: Implementing proper construction techniques and quality control measures during geogrid installation is vital. Ensuring adequate compaction of the reinforced soil, proper connection of the geogrid to the facing system, and accurate placement of the geogrid layers are important considerations for the long-term stability of the reinforced slope in seismic-prone areas.

- Yes, geogrids can be used in wastewater treatment applications. Geogrids are often used in the construction of wastewater treatment facilities to reinforce soil and prevent erosion. They can also be used to stabilize slopes and retain walls, which are common features in wastewater treatment plants. Additionally, geogrids are used to reinforce and separate different layers of soil, ensuring the stability and longevity of the wastewater treatment infrastructure.

- The tensile strength of a steel bar is about the number of cattle per square millimeter per square millimeter. The tensile strength of Gsa's cattle per meter, understand the carrying capacity of tensile Gsa every one meter in width is the number of cattle (considering Gsa gap), or single Gsa every one meter in length tensile capacity is the number of cattle (the size effect of Gsa does not consider the length direction). Please advise!

- Plastic mesh grille in custom-made case, first calculate the root number and the wire is thick, in the calculation of mesh size for tensile impact, your problem is that the tensile strength of steel grating is the tensile strength of each of the above. There are problems can be private chat, hope to adopt Thank you

- Yes, geogrids can be used in geothermal energy systems. Geogrids are commonly used in geothermal installations to reinforce the ground and provide stability for underground piping systems. They help distribute the weight and thermal load, reducing the risk of ground settlement and ensuring efficient heat transfer.

- Yes, geogrids are generally resistant to corrosion due to their material composition, which is typically made of high-density polyethylene (HDPE) or polypropylene (PP). These materials are highly resistant to chemicals, moisture, and environmental factors, making geogrids suitable for long-term use in various applications without the risk of corrosion.

- What is the geogrid GSJ80/HP

- 4, mixed with asphalt compatible materials - glass fiber geogrid treatment process after coating is designed for asphalt mixture, every fiber is fully coated with high compatibility with asphalt, so as to ensure that the glass fiber geogrid in the asphalt layer and not in isolation of asphalt mixture but, firmly together.5, physical and chemical stability, through special postprocessing agent coating, glass fiber geogrid can resist all kinds of physical and chemical erosion wear, can resist biological erosion and climate change, ensure that its performance is not affected.6, lock and limit the aggregate because of glass fiber geogrid is mesh structure, aggregate in asphalt concrete can be run through them, thus forming a mechanical interlock. This restriction hinders the movement of aggregates, so that the asphalt mixture in the case of load can achieve better compaction state, higher load capacity, better load transfer performance and smaller deformation.

- What is the single geogrid 60kN/m

- Unidirectional geogrid, the tensile strength is not less than 60 kn per meter

- Geogrids enhance the performance of flexible retaining structures by providing reinforcement and stability to the soil. They distribute the loads more evenly, reducing the stress on the structure and increasing its overall strength. Geogrids also prevent soil erosion and improve drainage, ensuring the long-term integrity and durability of the retaining structure.