Scaffolding Pulley

Scaffolding Pulley Related Searches

Stainless Steel Pulley Aluminum Timing Pulley Bar Stock Pulley Stock Aluminum Roller Pulley WheelsHot Searches

Scaffolding Manufacturer In Mumbai Physiotherapy Equipment Supplier In Malaysia Medical Equipment Suppliers In Kenya Electrical Equipment Price List Aluminium Scaffold Planks Sale Aluminium Walkway Mesh Prices Cost To Hire Scaffolding Scaffolding Sales Uk Scaffolding Manufacturers Uk Scaffolding Joints Types Scaffolding Bracing Types Scaffolding Types Ppt Scaffolding Company Names Harsco Scaffolding Company Wholesale Sound Equipment Electrical Equipment Company Petaluma Cleaning Equipment Suppliers Medical Equipment Suppliers Uk Rehabilitation Equipment ManufacturersScaffolding Pulley Supplier & Manufacturer from China

Okorder.com is a professional Scaffolding Pulley supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Scaffolding Pulley firm in China.Hot Products

FAQ

- There exist various global standards and regulations governing steel tube couplers in scaffolding. Among these, the EN 74-1 standard stands out as one of the most widely recognized. It is a European standard specifically tailored for couplers utilized in temporary structures like scaffolding. This standard outlines specific requirements in terms of dimensions, materials, and mechanical properties of the couplers. Moreover, the American National Standards Institute (ANSI) has developed its own set of standards for scaffolding couplers, namely ANSI/SSFI SC 100-5/05. These standards mandate specific requirements for the design, testing, and performance of couplers incorporated into scaffolding systems. Additionally, the International Organization for Standardization (ISO) has released ISO 9001, a quality management system standard that can be implemented in the manufacturing process of steel tube couplers. ISO 9001 ensures that manufacturers adhere to a set of guidelines aimed at producing couplers that meet designated quality requirements. For manufacturers, suppliers, and users of steel tube couplers in scaffolding, strict adherence to these international standards and regulations is crucial to guarantee the safety and dependability of scaffolding systems. By complying with these standards, one can ensure that the couplers employed in scaffolding possess high quality, have undergone adequate testing, and can withstand the loads and stresses associated with scaffolding structures.

- The common maintenance requirements for steel tube couplers include regular inspection, cleaning, lubrication, and replacement if necessary. Regular inspection is important to identify any signs of wear and tear, such as cracks, corrosion, or deformation, which can compromise the functionality and safety of the couplers. Cleaning the couplers is essential to remove dirt, debris, and any other contaminants that may accumulate over time and hinder their performance. Lubrication is another important maintenance requirement as it helps reduce friction between the couplers, ensuring smooth operation and preventing premature wear. It is recommended to use a suitable lubricant specifically designed for steel tube couplers. Additionally, if any couplers are found to be damaged or faulty during the inspection, they should be promptly replaced to maintain the integrity and reliability of the overall structure. Overall, regular maintenance and timely repairs or replacements are crucial to ensure the longevity and optimal performance of steel tube couplers.

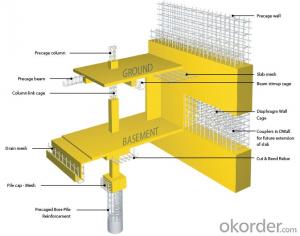

- Steel tube couplers are essential components of a scaffolding structure as they enable quick and secure connections between tubes. By eliminating the need for complex and time-consuming welding or drilling, couplers allow for easy and swift assembly and disassembly of scaffolding. This not only enhances the overall ease of movement and repositioning of the structure but also ensures its stability and safety during use.

- The overall cost of scaffolding projects can be significantly influenced by steel tube couplers. These couplers serve as vital components that connect steel tubes, creating a strong and dependable structure. The cost of these couplers can vary depending on several factors, including their type, quality, quantity needed, and the supplier. The type of steel tube couplers used is one aspect that affects the cost. There are various types available, such as swivel couplers, sleeve couplers, putlog couplers, and beam clamps. Each type has its own specifications, applications, and associated cost. For instance, swivel couplers are generally pricier than sleeve couplers due to their added flexibility and adjustable features. The quality of the steel tube couplers is also a factor that impacts the overall cost. High-quality couplers are typically more expensive but offer superior durability, strength, and resistance to corrosion. Investing in top-notch couplers can result in longer-lasting scaffolding structures, reducing the need for frequent replacements and maintenance, potentially reducing overall costs in the long term. The quantity of steel tube couplers required for a specific project directly affects the cost. Larger-scale projects that necessitate a significant amount of scaffolding will naturally require a greater number of couplers, leading to higher costs. It is crucial to accurately estimate the required quantity to avoid over-purchasing and unnecessary expenses. Lastly, the choice of supplier can also influence the cost of steel tube couplers. Different suppliers may offer varying prices for identical or similar products. It is essential to conduct research and compare prices from multiple suppliers to ensure the best value for money. In conclusion, steel tube couplers have a substantial impact on the cost of scaffolding projects. Considerations such as the type, quality, quantity, and supplier of the couplers should be carefully evaluated to optimize costs while maintaining the necessary safety and reliability of the scaffolding structure.

- The market offers a range of steel tube coupler sizes that vary depending on the specific application and industry requirements. Some commonly utilized sizes include 1/2 inch, 3/4 inch, 1 inch, 1 1/4 inch, 1 1/2 inch, 2 inch, and 2 1/2 inch. These sizes are typically available in both standard and metric measurements, catering to diverse global markets and regions. Furthermore, specialized applications or specific industries may have access to larger or smaller sizes. To ensure compatibility with your project or needs, it is crucial to consult with manufacturers or suppliers to ascertain the exact size range they offer.

- Yes, steel tube couplers are compatible with other scaffolding systems. These couplers are designed to connect steel tubes securely, providing a versatile and reliable solution for constructing scaffolding structures.

- Yes, steel tube couplers can be used in scaffolding projects involving complex or intricate geometries. These couplers are versatile and can be adjusted to fit various angles and shapes, allowing for the construction of scaffolding structures in intricate or irregular geometries.

- Yes, steel tube couplers can be used in scaffolding projects that require overhead protection or canopy. Steel tube couplers are designed to securely connect scaffolding tubes, allowing for the construction of stable and reliable structures. This makes them suitable for supporting overhead protection or canopy systems, providing a safe and effective solution for scaffolding projects that require such features.