Rebar Tensile Strength

Rebar Tensile Strength Related Searches

Tensile Strength Of Geogrid Car Fiberglass Fiberglass Roof Shingles Fiberglass French Doors Surfboard Fiberglass Repair Fiberglass Distributors Geogrid Tensile StrengthHot Searches

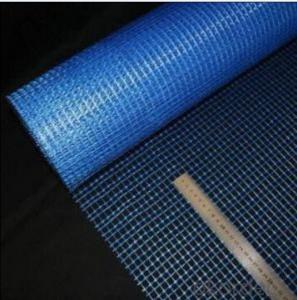

Geogrid China Geogrid Mesh Price Geogrid Fabric Price Geogrid Roll Price Geogrid Price List Tensar Triax 160 Geogrid Price Tensar Ss40 Geogrid Price Tensar Tx160 Geogrid Price Triax Geogrid Price Geogrid Price Tx160 Geogrid Price Geogrid Fabric Home Depot Tensar Type 2 Geogrid Type 2 Geogrid Home Depot Geogrid Geogrid Home Depot Geogrid Material Suppliers Geogrid Fabric Near Me Geogrid China Geogrid Mesh PriceRebar Tensile Strength Supplier & Manufacturer from China

Okorder.com is a professional Rebar Tensile Strength supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Rebar Tensile Strength firm in China.Hot Products

FAQ

- Geotextiles and geogrids to do the re inspection approach?

- In theory it is necessary

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used to reinforce soil and provide stability in retaining walls and structures. They are versatile and can be used in both permanent and temporary applications, making them suitable for various construction and engineering projects.

- Geogrids improve the performance of geotextile containers by providing additional tensile strength and stability to the structure. They reinforce the geotextile material, preventing it from stretching or sagging under the weight of the contained materials. This enhances the container's ability to retain its shape, withstand external forces, and overall improves its structural integrity.

- meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- The main purpose of filling subgrade is to use geogrid, which is to prevent the longitudinal cracking and sliding. As for Geogrid, it can not directly stabilize the slope, but also rely on geotextile wrapped. As for the soaking embankment, in addition to the use of Geogrid and geotextile, but also consider the problem of slope protection (such as stone, concrete surface etc.).Geogrid is usually used to fill the embankment with high height, in order to play a role. Also, you said that the protection of the ramp laying 1.4 meters, the laying of the roadbed in the area of 1.6 meters, these are trivial, can only play a part of the role of little. See you use the material is plastic geogrid, this is the worst kind of material, the strength is very low. Small size, low strength, not as good as the use of woven bags stacked slope. I guess this is a low grade road

- Yes, geogrids can be used in the reinforcement of embankments. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil structures, such as embankments. They are designed to distribute loads and provide support, reducing the potential for settlement and slope failure. By incorporating geogrids into the embankment design, the overall performance and durability can be improved, making them a suitable choice for reinforcement.

- Yes, geogrids can be used in railway track bed stabilization. Geogrids are commonly used in geotechnical engineering applications to improve the stability and performance of soil structures. In railway track bed stabilization, geogrids can provide reinforcement and increase the load-bearing capacity of the track bed, reducing settlement and improving overall stability.

- Yes, there are design guidelines for using geogrids in reinforcement applications. These guidelines provide recommendations and specifications on various aspects such as selecting the appropriate geogrid type, determining the required strength and stiffness properties, and establishing the proper installation and testing procedures. Additionally, these guidelines consider factors such as soil type, loading conditions, and environmental considerations to ensure effective and safe use of geogrids for reinforcement applications.