Platform Twin Bed Frame

Platform Twin Bed Frame Related Searches

Galvanized Steel Garden Bed Galvanized Steel Raised Bed Canister Sets Stainless Steel Aluminum Ball From Foil Fine Bone China Dinnerware Aluminum Diamond Plate Bed Rails Ball Aluminum Stock Iron Full Bed Frame Iron Frame Bed Pe TapeHot Searches

Used Hotel Patio Furniture For Sale Wicker Stools For Sale Outdoor Led Screen Price Alcoa Aluminum Stock Price Today 1 4 Aluminum Plate Home Depot 1/4 Aluminum Plate Home Depot 1 8 Aluminum Plate Home Depot Outdoor Led Screen Cost Outdoor Led Screen Manufacturers Outdoor Led Signs Wholesale 1/2 Inch Aluminum Plate Near Me 1/4 Inch Aluminum Plate Near Me 1 4 Inch Aluminum Plate Near Me Outdoor Led Signs Prices Led Signs Outdoor Prices Aluminum Trim Coil Near Me 1/2 Aluminum Plate Near Me 1 4 Aluminum Plate Near Me 1/4 Aluminum Plate Near Me 3/8 Aluminum Plate Near MePlatform Twin Bed Frame Supplier & Manufacturer from China

Okorder.com is a professional Platform Twin Bed Frame supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Platform Twin Bed Frame firm in China.Hot Products

FAQ

- Steel formwork proves to be an adaptable construction material capable of effectively managing architectural features like openings and recesses. Its strength and flexibility render it perfect for accommodating these design elements in concrete structures. In terms of openings, such as windows or doors, steel formwork can be easily customized to yield precise and well-defined openings. The formwork panels can be cut or shaped to the preferred size and shape, enabling accurate placement of the concrete around the opening. It also provides stability and support during the pouring and curing process, ensuring the structural soundness of the concrete surrounding the opening. On the other hand, recesses can be effortlessly formed using steel panels specifically engineered to create the desired recessed area. These panels can be shaped or molded to match the architectural design, facilitating a seamless integration of recesses into the concrete structure. Steel formwork allows for meticulous control over the depth and dimensions of the recess, guaranteeing compliance with the design requirements. In addition to its adaptability, steel formwork offers several advantages when dealing with architectural features. Its durability and resistance to deformation enable it to withstand the pressure exerted by the concrete, thereby preserving the formwork's shape throughout the construction process. This is crucial in maintaining the accuracy and integrity of architectural features. Moreover, steel formwork is reusable, making it a cost-effective option for projects involving multiple openings and recesses. The panels can be disassembled, cleaned, and reassembled for future use, reducing the need for new formwork materials and minimizing waste. To summarize, steel formwork is a dependable and efficient choice for managing architectural features like openings and recesses. Its strength, flexibility, and reusability make it an ideal construction material for creating precise and visually appealing architectural designs.

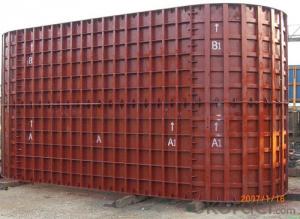

- Certainly, circular columns can be constructed using steel formwork. Steel formwork possesses great versatility and can be conveniently molded into different shapes and sizes, including circular structures. Its exceptional strength and durability make it ideal for projects requiring formwork that can withstand substantial loads and frequent utilization. Moreover, steel formwork can be easily modified and utilized repeatedly, resulting in cost-effective circular column construction. Typically, the steel formwork is meticulously designed and produced to perfectly align with the precise dimensions and radius of the circular column, guaranteeing an exact and precise formwork system.

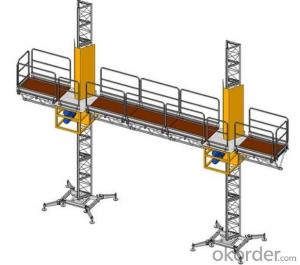

- Yes, steel formwork can be used for temporary structures. Steel formwork is durable, strong, and can withstand heavy loads, making it suitable for temporary structures such as scaffolding, shoring, and temporary supports. Its versatility and reusability make it a popular choice in construction projects requiring temporary structures.

- The time required to set up steel formwork can vary depending on the complexity of the project, the size of the structure, the experience of the workers, and the availability of resources. However, typically it can take a few hours to a few days to set up steel formwork for a construction project.

- Steel formwork contributes to the construction process by providing a durable and reusable framework for concrete pouring. It ensures accurate shaping and alignment of the structure, allowing for efficient construction and reduced labor costs. Additionally, steel formwork offers increased strength and stability, enabling the creation of complex and high-rise structures with precision.

- When it comes to designing steel formwork for heritage buildings, there are several common considerations that need to be taken into account. These considerations aim to preserve the historical and architectural value of the building while ensuring efficient construction processes. Some of the key design considerations for steel formwork in heritage buildings include: 1. Historical Preservation: The primary goal in designing steel formwork for heritage buildings is to preserve and protect the historical elements of the structure. The design must respect the original architectural features, materials, and construction methods of the building while ensuring the formwork adequately supports the weight of the concrete during construction. 2. Structural Integrity: Steel formwork should be designed to provide sufficient support and stability to the structure during the concrete pouring and curing process. It is crucial to consider the load-bearing capacity of the formwork and ensure it can withstand the weight of the concrete, reinforcing bars, and construction equipment without causing any damage to the heritage building. 3. Flexibility and Reusability: Since heritage buildings often require restoration or repairs over time, it is essential to design the steel formwork in a way that allows for easy disassembly and reusability. This consideration ensures that the formwork can be removed without causing any damage to the building and can be reused for future construction projects. 4. Aesthetics: In heritage buildings, maintaining the original architectural aesthetics is of utmost importance. The design of steel formwork should consider the visual impact it will have on the structure. This may involve incorporating decorative elements or finishes that match the existing architectural style or using formwork that can be concealed or removed once the concrete is set. 5. Accessibility and Safety: The design of the steel formwork should take into account the safety requirements for the construction workers and the general public. It should ensure safe access to different areas of the building during construction and minimize any potential risks or hazards associated with formwork installation and removal. 6. Environmental Considerations: Sustainable design practices should be considered when designing steel formwork for heritage buildings. This may involve using recycled or low-impact materials, minimizing waste generation, and implementing energy-efficient construction techniques. In conclusion, the design considerations for steel formwork in heritage buildings revolve around historical preservation, structural integrity, flexibility, aesthetics, accessibility, safety, and environmental sustainability. By addressing these factors, architects and engineers can ensure that the construction process respects the heritage value of the building while meeting modern construction standards.

- Steel formwork is known for its durability and strength, which makes it highly efficient in handling formwork stripping time. Unlike traditional wooden formwork, steel formwork can withstand multiple uses without compromising its structural integrity. This means that the stripping time for steel formwork is significantly reduced compared to other formwork materials. Due to its rigid construction, steel formwork can support the weight of concrete and resist deformation during the pouring and curing processes. This allows for faster stripping of the formwork after the concrete has set, as there is less concern about damaging or warping the formwork. Additionally, steel formwork is designed to have smooth and non-porous surfaces. This characteristic prevents the concrete from adhering to the formwork, making the stripping process even easier and quicker. The smooth surface also contributes to a better finish of the concrete, reducing the need for additional finishing work. Moreover, steel formwork systems often incorporate adjustable features, such as adjustable props and modular panels. These features enable the formwork to be easily adjusted and repositioned, further enhancing the efficiency of the stripping process. This adaptability allows for faster stripping and reusability of the formwork, resulting in significant time and cost savings. In conclusion, steel formwork handles formwork stripping time exceptionally well due to its durability, strength, and smooth surface. Its ability to withstand multiple uses, resist deformation, and prevent concrete adhesion makes steel formwork highly efficient and time-saving in the construction industry.

- Steel formwork plays a crucial role in contributing to the overall structural integrity of a building. Firstly, steel formwork provides a robust framework for pouring and shaping concrete, ensuring that it maintains the desired shape and dimensions during the construction process. This is particularly important for complex or irregular structures, where the use of steel formwork allows for accurate and precise construction. Furthermore, steel formwork offers excellent strength and durability, which enhances the structural integrity of the building. Steel is inherently strong and can withstand heavy loads, making it suitable for supporting the weight of concrete and other construction materials. This strength ensures that the formwork remains stable and secure, preventing any potential collapse or deformation during the construction process. Additionally, steel formwork provides excellent dimensional stability, which is vital for maintaining the structural integrity of the building. Steel is resistant to warping, shrinking, or expanding due to changes in temperature or humidity, ensuring that the formwork retains its shape and does not compromise the structural stability of the building. Moreover, the use of steel formwork allows for efficient and speedy construction, which can also contribute to the overall structural integrity of the building. Steel formwork systems are reusable and can be easily assembled and disassembled, enabling faster construction cycles. This reduces the risk of errors or delays, ensuring that the building is constructed in a timely manner and minimizing potential structural issues that may arise from prolonged construction periods. In conclusion, steel formwork is essential for ensuring the overall structural integrity of a building. Its robustness, strength, dimensional stability, and efficiency contribute to the accurate construction and support of the building's structural components, ultimately ensuring its safety and durability.