Iron On Melamine Sheet

Iron On Melamine Sheet Related Searches

Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiber Sheet For Roof Plastic Wall Coverings For Bathrooms Plastic Corner Protectors For Furniture Decorative Lights For Ceiling Plastic Netting For Gardens Ceiling Brackets For Lights Hanging Ceiling Chairs For Bedrooms 42 White Ceiling Fan With LightHot Searches

Hdf Board For Sale sintra board for sale Gypsum Board Price Per Sheet In India High Density Mdf Board Suppliers 5 8 Type X Gypsum Board Price Lasani Wood Sheet Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Mdf Price Per Sheet Pre Laminated Board Price List 4Mm Mdf Sheet 1220X2440Mm Price 6Mm Mdf Board Price 18Mm Ply Board Price Ply Board Price List Partex Board Price List Hdf Board Price India 19Mm Ply Board Price Hpl Board Price Magnum Board PriceIron On Melamine Sheet Supplier & Manufacturer from China

Okorder.com is a professional Iron On Melamine Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Iron On Melamine Sheet firm in China.Hot Products

FAQ

- Steel sheets are typically stored in a dry and climate-controlled environment to prevent damage. They are stacked flat and evenly, with proper support between each sheet to avoid warping or bending. Additionally, protective coverings such as plastic sheets or cardboard are often used to shield the steel sheets from moisture, dust, and other potential sources of damage.

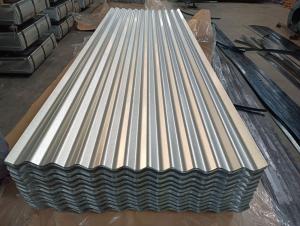

- Yes, steel sheets can be used in architectural applications. Steel sheets are often used in architectural projects for their durability, strength, and versatility. They can be used in various applications such as roofing, cladding, facades, flooring, and structural elements. Steel sheets offer a wide range of design options and can be customized to meet specific architectural requirements. Additionally, their corrosion resistance and fire resistance properties make them suitable for long-lasting and safe architectural solutions.

- Yes, steel sheets can be bent or curved using various methods such as press brakes, rollers, or heat treatment techniques.

- The typical impact strength of a steel sheet can vary depending on various factors such as the grade and thickness of the steel, as well as the specific testing method used to measure impact strength. However, steel sheets generally exhibit high impact strength, making them resistant to cracking or breaking under sudden or dynamic loads.

- There exist several methods for joining steel sheets, each with its own benefits and applications. 1. Welding, a widely used method, involves melting and fusing the sheet edges together with heat. Various welding techniques, such as arc, MIG, TIG, and spot welding, are available. Welding ensures robust and durable joints but demands skilled operators and can be time-consuming. 2. Bolting, another method, employs bolts or screws to connect steel sheets. This method is commonly preferred when disassembly or maintenance is necessary. Bolting guarantees strong and reliable joints, and it is relatively simple and quick. However, it may involve drilling holes and result in a less visually appealing appearance compared to welding. 3. Riveting, a method utilizing metal pins or rivets, effectively joins steel sheets. Rivets are inserted through pre-drilled holes and then deformed or expanded to secure them in place. Riveting ensures strong and secure joints, commonly used in applications requiring high shear strength. Nevertheless, it can be time-consuming and necessitates specialized tools and skills. 4. Adhesive bonding involves using specialized adhesives or bonding agents to join steel sheets. The adhesive is applied between the sheets and forms a strong bond as it cures. Adhesive bonding provides excellent aesthetics, leaving no visible joints, and evenly distributes stress across the joint. It finds common use in industries where welding or other methods are unsuitable, such as automotive and aerospace sectors. 5. Clinching utilizes mechanical force to join steel sheets. It entails deforming the sheet edges to interlock them and create a strong joint. Clinching is cost-effective as it does not require additional materials like fasteners or adhesives. However, it may not be suitable for applications requiring high load-bearing capacity. Ultimately, the choice of joining method for steel sheets depends on factors such as the application, desired strength, aesthetics, time constraints, and cost considerations. Each method possesses its own advantages and limitations, necessitating the selection of the most appropriate method for the specific project requirements.

- Steel sheets can vary in thickness depending on their intended use, but they are typically available in thicknesses ranging from 0.5mm to 6mm for general applications.

- Yes, steel sheets are suitable for high-pressure applications. Steel is known for its strength, durability, and resistance to deformation, making it an ideal material for withstanding high pressures.

- The average wind load capacity of steel sheets can vary depending on various factors such as sheet thickness, size, shape, and the specific steel material used. It is typically determined by conducting engineering calculations and considering local building codes and standards. Therefore, it is not possible to provide a specific average wind load capacity without knowing the specific details of the steel sheets in question.