Interax Geogrid

Interax Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleInterax Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Interax Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Interax Geogrid firm in China.Hot Products

FAQ

- Geogrids offer several benefits in pavement construction, including improved stability and load-bearing capacity, reduced cracking and rutting, increased pavement lifespan, and cost savings. By reinforcing the soil or aggregate base, geogrids distribute the load more evenly, preventing the formation of potholes and reducing maintenance requirements. Additionally, they enhance the overall structural integrity of the pavement, making it more resistant to heavy traffic and environmental factors such as freeze-thaw cycles. Ultimately, utilizing geogrids in pavement construction leads to longer-lasting, more durable roads with reduced maintenance needs, resulting in cost savings over time.

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the clay liner. They help distribute the loads more evenly, reduce soil movement, and prevent erosion by reinforcing the liner's tensile strength. This enhances the overall effectiveness and longevity of the erosion control system.

- What is the minimum net size of geogrid mesh center?

- The specific requirements of the customer to see there needs, like glass fiber and polyester, there are two types, one large and one small, mesh size and steel PP welding can be adjusted, the specific requirements of the customer to see what kind of need, generally according to their requirements to do this.

- Where the geogrid is the cheapest! Plastic fiber polyester fiberglass geogrid there?

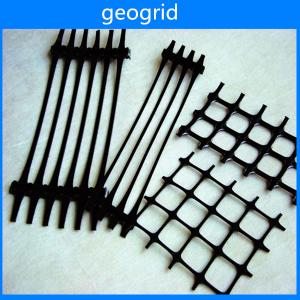

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. 1) Plastic Geogrid

- Dimensions of U shaped steel nails for geogrids

- U type nails, like the letter U, geogrid generally 0.6 multiplied by 80. You can also process.

- Geocell of earthwork grid construction method

- 4, permafrost subgradeIn the construction of embankment in permafrost regions, should reach the minimum height of fill, to prevent the occurrence of frost or freezing layer caused by upper limit decreased, resulting in the occurrence of excessive settlement of embankment. The whole side reinforcing effect of geocell specific and effective implementation, to the maximum extent to ensure that the minimum height of fill in some special area, and the high strength and stiffness of soil.5, loess collapsibility roadbed treatmentFor the highway and the highway through the collapsible loess and loess compression lots better, or high embankment foundation and embankment load is lower than the vehicle to allow the weight bearing pressure, should also be in accordance with the requirements of the subgrade bearing capacity, then the geocell superiority will undoubtedly show the.6, saline soil, expansive soilThe saline soil, expansive soil and construction of the highway, a highway, the road shoulder and slope reinforcement measures are used, the reinforcement effect of geocell facade is a reinforcement material in all the best, and it has excellent corrosion resistance, can fully meet in saline soil, expansive soil has higher requirements for highway.

- Geogrids help in reducing the use of natural resources by enhancing the stability and strength of soil, thus reducing the need for excessive excavation and the use of traditional construction materials like stone or concrete. This results in less dependence on natural resources and promotes sustainability in construction projects.

- The load-bearing capacities of geogrids vary depending on the specific type and design of the geogrid, as well as the soil conditions and application. However, geogrids are typically engineered to have high tensile strength and can support heavy loads, ranging from several hundred to several thousand kilonewtons per meter.